THE THIRD RAIL SYSTEM

ON THE NEW HAVEN RAILROAD.

THE THIRD RAIL SYSTEM

ON THE NEW HAVEN RAILROAD.

Scientific American—July 12, 1897

The third rail system of electric traction is now in permanent

operation on an important section of a leading steam railroad.

The recent opening of the line from Berlin to New Britain and

from New Britain to Hartford, while it is by no means the first

successful operation of third rail traction, is notable as being

its first application in a permanent way to the lines of a standard

steam railroad.

The first extensive test of this system took place within the

grounds of the World's Fair, at Chicago, where its operation was

very satisfactory. It was then adopted on the elevated roads of

Chicago, where it has given reliable service. The Brooklyn Bridge

trustees decided that it was adapted to the requirements of bridge

traffic, and laid a third rail on the outside of the tracks. The

equipment has given a good account of itself, especially in the

switching operations at the terminal stations.

It is stated by Col. N. H. Heft, chief of the electrical department

of the New York, New Haven & Hartford Railroad, who has afforded

us every facility in the preparation of the present article, that

the probability of electricity entering largely into the operation

of steam railroads was suggested to the directors by Mr. Clark

in his annual presidential report made in 1891. It was natural

that the attention of this company should be turned to the question

of electric traction, for the reason that their passenger traffic

was being exposed to severe competition from the network of suburban

and interurban trolley lines which have sprung up throughout the

country served by the New Haven road. Fully one-half of the gross

receipts of this road is realized from passenger traffic and a

large proportion of this is obtained from local traffic, of a

character for which suburban trolley car service has most attraction.

The first step taken by the company was to form an electrical

department, and give orders for the electrical equipment of a

stretch of their road which runs from Nantasket Junction to Pemberton,

Mass. This equipment, which is commonly known as the Nantasket

Beach line, was put in operation in 1895. Overhead conductors

were used and the experiment was highly successful. The company

then determined to test the third rail system of transmission,

and a trial line was laid down in 1896, when an additional 3½

miles of road was placed in service. The operations at Nantasket

were regarded by the company as being experimental and preparatory

to a further extension of the system. The results were so promising

that it was determined to apply the system on a larger and more

permanent scale, embodying in the new line the results of previous

experiments.

The equipment

which has recently been put in operation is applied to two lines

of steam railroad, one extending from New Britain to Berlin and

the other from Hartford to New Britain, the total length of the

line from Hartford to Berlin being 12.3 miles. The equipment

which has recently been put in operation is applied to two lines

of steam railroad, one extending from New Britain to Berlin and

the other from Hartford to New Britain, the total length of the

line from Hartford to Berlin being 12.3 miles.

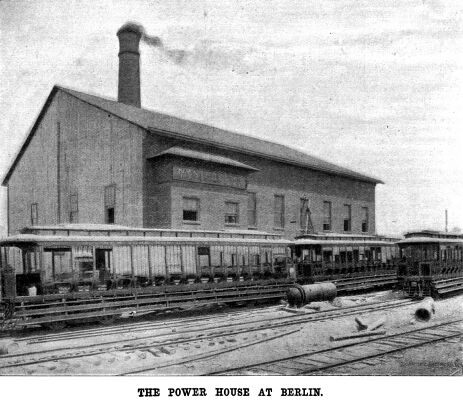

The power station has been built with a view to its enlargement

as the electric equipment is extended. The building shown in the

accompanying engraving is 106 feet wide by 117 feet in length,

the end on which the extension will be added being temporarily

walled in with wood planking. The present building contains two

stories in the front devoted to the engine and generators, etc.,

and a boiler room in the rear extending the full height of the

building. A 1,200 horse power engine is already in place and the

foundations have been built for a second. There is room in the

building for a third engine when the extension of the line calls

for it. Further details regarding the engines and the boilers

will be given in a later issue. The engine is direct connected

to a General Electric Company's standard 10 pole, 850 kilowatt

generator of the well known ironclad type, which furnishes current

at 600 volts no load and 650 volts full load.

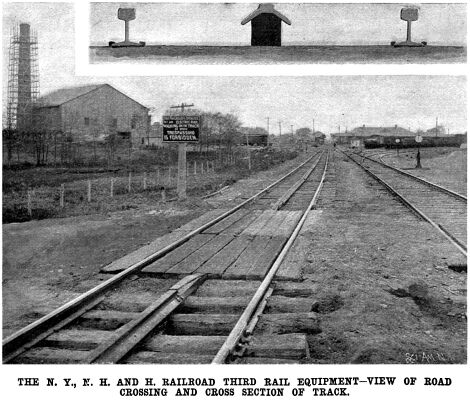

The third rail conductor is of a special section rolled for

this purpose. It resembles somewhat a flattened A,

the flanges forming a protection to the insulating blocks upon

which it is laid. The rail is heavy, weighing ninety-three pounds

to the yard, and it is found that wooden blocks saturated with

insulating material give excellent service, and three to the rail

are found to be sufficient. The flanges of the rail come within

1½ to 1-five-eighths inches of the top of the ties, the

head of the rail being one inch higher than the main rails. It

will be seen that this conductor is carried much lower than that

on the Nantasket line, the difference being due to the height

of the main rails. The ends of the rail are bonded by sheet copper

plates one-eighth inch thick, 4½ inches wide and 12 inches

long, which are held against the under side of the flanges at

the rail ends by iron plates. The latter are bolted to each rail

by sixteen bolts, eight for each plate, the copper bonds being

sandwiched between the iron plates and the rail. The capacity

of each bond is 900,000 circular mils, the double bond having

more than the carrying capacity of the rail itself.

On the whole

line there are twenty-two grade crossings, at each of which the

third rail is replaced by underground cables of 850,000 circular

mils. The cables are drawn into creosoted wooden conduits filled

with an insulating material made of residuum and asphalt. The

conduits are laid in creosoted wooden troughs filled with the

same material, which are buried in the earth. Special attention

has been paid to the return circuit, as it is the opinion of Col.

Heft that the importance of this element is too often overlooked

in the construction of electric roads. The company has put in

leaf bonds of 550,000 circular mils, and these are attached to

the base of the rail in preference to the web, and are secured

by wedge fastenings. In order to prevent any interruption to the

current when a train is passing over switches and crossings a

shoe is provided on the rear car of a two-car train. This insures

that connection will be made by the shoe of the motor car before

the shoe of the second car has entered the gap. On the whole

line there are twenty-two grade crossings, at each of which the

third rail is replaced by underground cables of 850,000 circular

mils. The cables are drawn into creosoted wooden conduits filled

with an insulating material made of residuum and asphalt. The

conduits are laid in creosoted wooden troughs filled with the

same material, which are buried in the earth. Special attention

has been paid to the return circuit, as it is the opinion of Col.

Heft that the importance of this element is too often overlooked

in the construction of electric roads. The company has put in

leaf bonds of 550,000 circular mils, and these are attached to

the base of the rail in preference to the web, and are secured

by wedge fastenings. In order to prevent any interruption to the

current when a train is passing over switches and crossings a

shoe is provided on the rear car of a two-car train. This insures

that connection will be made by the shoe of the motor car before

the shoe of the second car has entered the gap.

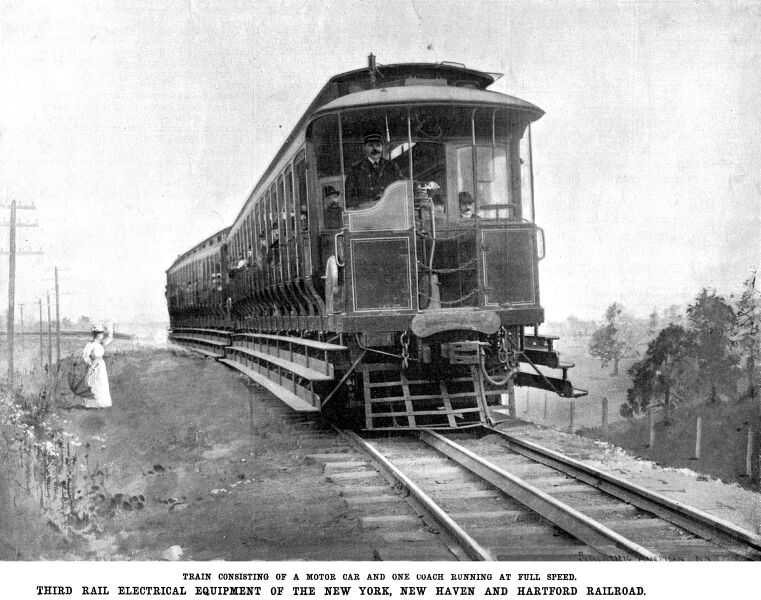

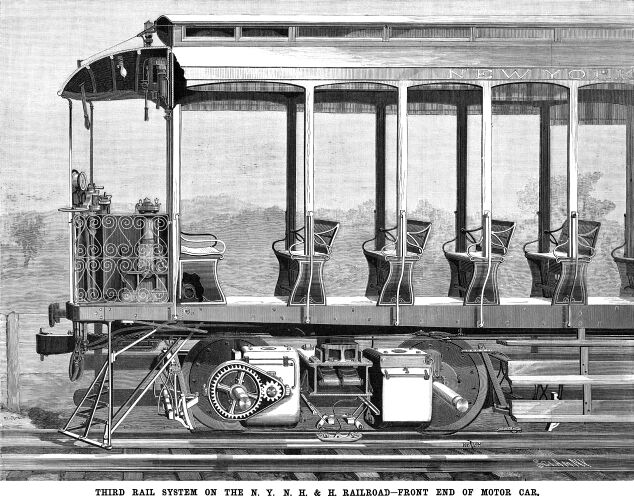

The general appearance and mechanical details of the open cars

are shown very clearly in our front page and other illustrations.

They are 51 feet long, and are provided with sixteen seats, each

of which can accommodate six passengers, the capacity of a two-car

train being, therefore, 192 passengers. The current is taken from

the third rail by means of a sliding contact shoe, which consists

of a simple cast iron plate 5 inches wide by 12 inches long, weighing

about 12 pounds. It is carried by an insulated support, to which

it is fastened by jointed links, which allow it to bear upon the

rail at all times with a pressure due to its own weight. Each

train is made up of a motor car and a trailer. Each motor car

has two 125 horse power motors, both of which are mounted upon

one track, as shown in the accompanying engraving, in which the

casing has been removed to show the gearing of the forward motor.

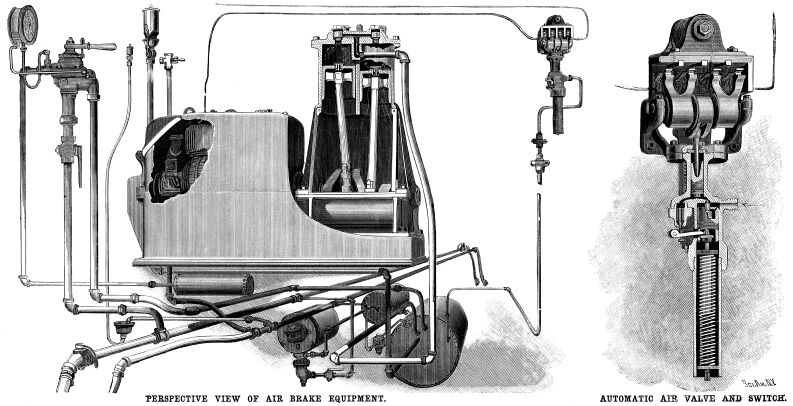

It can well be understood that in a service of this kind, where

the high speeds which are customary in the steam service are to

be regularly made, special attention had to be given to the question

of braking. As hand-operated brakes were out of the question and

steam was not available, it was determined to equip the motor

cars with a separate electrically driven air brake plant. The

details of this successful and highly creditable work are shown

in the upper front page engraving and its position on the front

platform is shown in the side view of the car.

The two cylinder, single acting compressor is driven by a direct

connected 10 horse power motor. The compressor has a capacity

of 52½ cubic feet of air per minute under a gage pressure

of 90 pounds per square inch. The speed is 250 revolutions per

minute and the consumption 16 amperes at 600 volts. The standard

Westinghouse air brake equipment of the company is used on the

cars, and it is controlled by the usual engineer's valve, as shown

in the engraving. One of the most ingenious features is the automatic

valve and switch for starting and stopping the compressor, of

which a sectional view will be found on the front page. By reference

to the engraving it will be seen that air is led in above a small

piston, which works in a vertical cylinder and is pressed upward

by a coil spring. The spring is set at the working pressure of

90 pounds to the square inch. As soon as the air pressure exceeds

90 pounds, the piston is forced down, carrying with it a small

vertical valve stem and allowing the air to pass up into a small

Cylinder located beneath the electrical switch which controls

the motor of the air compressors. Here it pushes up a piston which

throws over the electrical contacts and opens the switch. As the

air pressure falls it releases the lower piston, which rises to

its normal position. As it rises, a catch on the piston rod lifts

the small lever shown to the left and opens a release valve below

the switch cylinder above mentioned. The upper piston now falls

and closes the switch, thereby starting the motor of the air compressor.

The device has given complete satisfaction. It may be set to work

at from 45 to 100 pounds pressure, and on a variation of from

5 to 7 pounds pressure.

The air compressor

is placed, as shown, on the front platform of the car to the left

of the motorman. In front of the compressor is the wheel of the

hand brake, and conveniently arranged in front of the motorman

are the pressure gage, the engineer's air valve and the controller.

The lever for operating the air chime whistle passes through the

hood just above the motorman's head. Beneath the hood on the front

of the car above the door are the current breaker and the main

switch. On the front rail of the platform there is also a conductor's

signal whistle. The air compressor

is placed, as shown, on the front platform of the car to the left

of the motorman. In front of the compressor is the wheel of the

hand brake, and conveniently arranged in front of the motorman

are the pressure gage, the engineer's air valve and the controller.

The lever for operating the air chime whistle passes through the

hood just above the motorman's head. Beneath the hood on the front

of the car above the door are the current breaker and the main

switch. On the front rail of the platform there is also a conductor's

signal whistle.

The current passes from the shoes through flexible copper cables

to the circuit breakers. After passing through these it is led

through a lightning arrester and a "kicking coil." It

then divides, passing to the controllers on each platform. At

each controller it passes through a magnetic blow-out coil, and

is led by cable to the resistance situated in the center of the

car. It then returns through the resistance contacts to the controller

cylinder and the motors.

The danger to the public from the use of the third rail is

considerably less than is popularly supposed, and in view of the

precautions which have been taken to safeguard the ignorant or

unwary, the chance of accident is very small. At the Berlin and

Hartford stations the third rail section is fenced in on both

sides. At New Britain, where the two lines converge, a switchman's

tower has been built in the Y

where the roads converge. Underground cables connect the rail

where it enters the station with a switchboard in the tower. When

a train has stopped in the station the third rail is cut out,

and it is not thrown in until the train is ready to start again.

When the road which has now been electrically equipped was

operated by steam, eight trains a day were run each way between

Hartford and New Britain, and fourteen trains a day between New

Britain and Berlin. Under the present system of two-car trains

will be run every half hour between Hartford and New Britain from

six in the morning till twelve at night. The run of 9.3 miles

will be made in something under twenty minutes, and the fare will

be ten cents each way. Sixteen trains a day will be run between

New Britain and Berlin, a distance of three miles, the fare being

five cents for a single trip.

We reserve further particulars and illustrations of this interesting

plant for a later issue.

Electric Article 2 | Lines

West | Stories Page | Contents

Page

This page originally appeared on Thomas Ehrenreich's Railroad Extra Website

|