EARLY RAILS, SILLS, A STONE BLOCKS.

DETAILED DESCRIPTIONS OF THE METHODS USED ON THE

PHILADELPHIA AND COLUMBIA RAILROAD

The exact nature and cost of the methods adopted on the Philadelphia

and Columbia Railroad are shown by the following data extracted

from a note-book in which Mr. W. Hasell Wilson commenced writing,

in 1831, such information as he considered valuable, while he

was acting as principal assistant engineer on that road, under

the direction of his father, Major John Wilson, chief engineer:—

Description and Estimate of Granite Railway,

as Laid on the

Columbia and Philadelphia Railway.

SILLS.—The sills are in lengths of not less than

three feet; the size, one foot square, or containing not less

than a square foot in the cross section, none, however, being

less than eight inches in depth; the shape as nearly square as

possible; the bed and upper surface, particularly, ought to be

parallel. The upper surface is dressed for about five or six inches,

to afford a smooth bearing for the iron. That part of the sill

outside of the iron is reduced to the same level, but not so smoothly.

The ends of the sills are dressed square, so as to be in contact

for at least three inches in depth below the iron, and for six

inches across the stone, exclusive of the chamfering.

BROKEN STONE.—The broken stone, the particles of

which must not be larger than it cube of two inches, are to be

kept clear from earth, clay, or other material.

TRENCHES.—The trenches are not less than two feet

in width, and twenty-two inches in depth, below the top of the

sill, except where the stone sill is wider than one foot, and

where rock occurs in the trench. In the former case, the trench

is made of such width as to admit of four inches of broken stone

on each side of the sill; in the latter, the depth will be such

as to allow four inches of broken stone under the sill.

LAYING.—The broken stone are placed in layers of

three inches, each layer well compacted with a heavy rammer. The

sills are then laid, and bedded with a heavy rammer.

The Holes are then drilled to correspond with the holes on

the bars, and to suit the width and position of the track, not

less than three and a half inches in depth, and five-eighths in

diameter. No hole is drilled within three inches of the end of

a sill. The plugs are of seasoned locust, fitting the hole exactly,

but not requiring much driving. The bar is then spiked on, and

the inner edge of the sill chamfered off, in width two inches,

and in depth one inch and a half.

THE HORSE PATH is filled in, and the earth sloped from the

back of the sills, to turn off the water collecting on the surface.

THE IRON BARS are in lengths of fifteen feet, two and a quarter

inches in width, and five-eighths of an inch in thickness. The

spikes are three and a half inches in length, and three-eighths

of an inch square, the heads fitting the countersink of the bar.

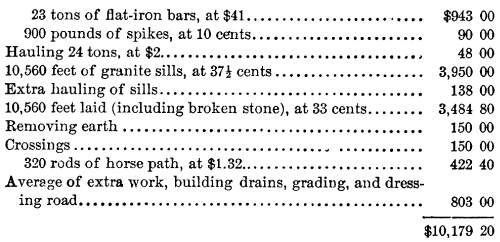

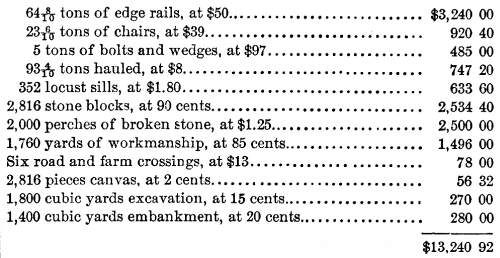

Estimate for One Mile of the Granite Railway, as Completed

by Robinson, Carr & Co.

Description and Estimate of a Wooden Railway.

SILLS.—The sills are chestnut, white oak, or chestnut

oak, seven and a half feet in length, and of such size as to square

seven inches, dressed flat on the under side, and notched on the

tipper.

TRENCHES.—The trenches are four feet apart, from centre

to centre, one foot in width, sixteen in depth (making twenty-four

inches to top of wooden rail), and eight feet in length.

RAIL.—The wooden rail is yellow pine, six inches square.

The keys are of white oak or yellow pine, one foot in length,

two inches in height, and one inch and a half thick, tapering

to three-quarters.

In notching the sills for the rail, there must be left at least

three inches of a bearing under the rail.

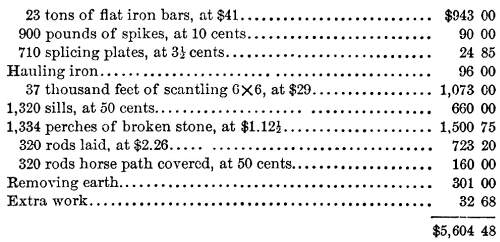

Estimate for One Mile of Wooden Railway as Completed

Edge Rails on Stone Blocks and Stone Sills, as

Laid Between Broad Street and Schuylkill River.

BLOCKS.—The blocks are of granite, twenty inches in length,

sixteen in width, and twelve in depth; depth of holes, six inches;

diameter, one inch.

SILLS.—The transverse sills are of granite, six and a

half feet in length, and twelve inches square. These are placed

it the joining of the bars, about fifteen feet front centre to

centre.

TRENCHES.—The trenches are twenty-eight inches wide, and

twenty-four inches deep (from the top of the block).

LAYING.—The broken stone are placed in layers of three

inches, well rammed; the blocks and sills then laid, three feet

apart from centre to centre. They are then drilled, the chairs

fastened on, and the iron bars laid and keyed. The broken stone

are now rammed around the blocks and sills, and the horse path

filled in.

THE IRON is the same as that used on the Wigan railway, the

rail weighing forty-one and a quarter pounds to the yard. Between

the chair and block a piece of canvas is inserted (the size of

the chair), soaked in tar.

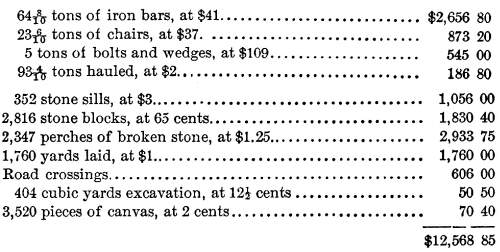

Estimate for One Mile of Edge Rails on Stone Blocks and

Sills, as Completed.

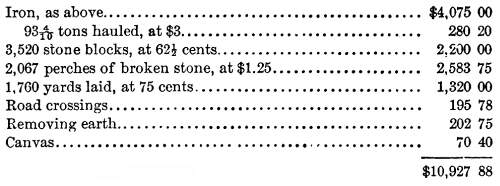

Estimate for One Mile, Without Stone Sills, as Laid.

Description and Estimate of Edge Rails on Stone Blocks

and Locust Sills, as Laid Between Columbia and the Intersection

of the West Chester Railway.

BLOCKS.—Granite, limestone, or sandstone, 22in. x 16 in.

x 12in.

SILLS.—Locust 7½ feet long, 6 x 8 inches, laid

15 feet apart, and on the flat side; in the curves they are placed

9 feet apart. The rails are not joined on the sills, but on the

nearest blocks, but not opposite. A cross trench is dug for each

sill, and filled with broken stone, which, on the embankments,

is continued out to the edge of the bank, thereby serving as a

drain. Between the rails, the space is filled up with earth to

a level with the top of the blocks. The holes in the blocks are

drilled six inches in depth, and one and a half inches in diameter,

then plugged with red cedar, which is previously bored through

the centre, half an inch in diameter, the bolt being five-eighths.

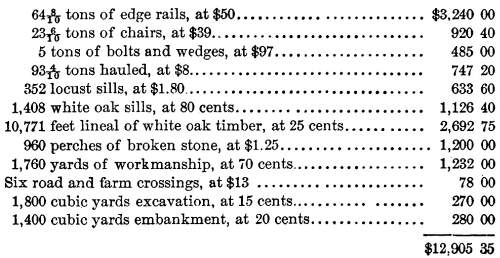

Estimate for One Mile of Edge Rails on Stone Blocks

and Locust Sills; Prices Averaged from Contracts Completed.

Description and Estimate of Edge Rails on Wooden

Cross Sills and Bearing Timbers.

THE BEARING TIMBERS are white oak, 10 x 12 inches, and in lengths

of not less than 20 feet, laid edgewise, and notched down two

inches, every three feet, to receive the cross sills.

At the joinings of these timbers, there is a tenon 4 inches

thick, and the whole width of the timber, laying horizontally

across the centre of the stick, and projecting six inches with

a mortice (to fit) on the opposite stick, secured by a wooden

pin. The sills are 7½ feet long, 6 x 8 inches, of white

oak, or chestnut, except at intervals of 15 feet on the straight

lines and 9 feet oil the curves, where they are of locust. They

are laid on the flat side, and secured to the bearing timbers

by wooden keys.

Estimate for One Mile of Edge Rails Upon Bearing Timbers

and Sills, with Locust Sills at Every Fifteen Feet.

It will be seen that the estimates given above relate to six

styles or variations in construction. The word sills is sometimes

used to indicate wood or stone which performed functions similar

to those now entrusted to ties, especially when they are called

cross sills, and sometimes to indicate a continuous foundation

on which rails were laid; and the relatively small number of cross

sills (or ties) used, indicates that at the Outset the danger

of the tracks spreading was not fully realized. It is somewhat

surprising, too, to note how nearly one of the systems adopted

approximated to modem methods in the matter of creating a foundation

of broken stone, and using wooden cross sills or ties.

"SNAKE HEADS."

A large proportion of the early railway tracks represented

close imitations of a style adopted by early coal roads, consisting

of bars of iron spiked on stringers of wood, and this style was

so extensively employed, and continued in use in some sections

for such a protracted period, that "snake heads" became

one of the recognized and most important of early railway perils.

This term was suggested by the liability of the iron bar to become

loosened from its fastenings as a train moved over it, and it

would sometimes suddenly turn upward with sufficient force to

pierce the bottom of cars, and occasionally injure passengers,

or throw a train from the track. As it was not until near the

middle of the fifth decade of the nineteenth century that iron

rails were manufactured in this country, except a few cast-iron

rails and flat bars, it was necessary to import all rolled-iron

rails that were used here, and this operation, together with the

large amount of iron required even by the edge rails then used,

necessitated a greater expenditure than could be afforded by many

of the earlier companies.

Horatio Allen, chief engineer of the South Carolina Railroad,

which had 10 miles in operation in 1830, and increased this mileage

by 52 miles in 1832, and 75 miles in 1833, and which for a time

enjoyed the distinction of being the longest continuous railway

in the United States, and the first to use a locomotive of American

construction, says of this road, that "it was of the age

of wooden rails capped with iron. Confidence and capital had not

yet reached the growth to make an iron track of the most modest

weight per yard a possibility, and steel rails were as unthought

of as the telegraph. On timber rails, 6inch X12-inch section,

iron bars 21-ineb x ½-inch were spiked. The wood was the

southern pine, the bard, resinous surface of which was as suitable

for the iron bars as wood could be."

The South Carolina was one of the first companies to substitute

edge or iron rails for iron bars or plates over its entire line,

as this course was adopted a few years after the completion of

the road. The desire of engineers and managers to secure such

an advance was very general, as they fully appreciated its importance,

and explained the advantages derived from its use in the way of

saving operating expenses, but the difference in cost of construction,

when comparatively heavy edge rails were used, was at one time

estimated at about $6,000 per mile, and this outlay was too great

to be borne by most of the early companies. The result was that

flat bars continued to furnish the iron for many tracks during

a protracted period. In 1839 all the New York railways, except

the Long Island, used flat bars. All the railways in Pennsylvania

used iron plates or bars, varying in dimensions from 1½

x three-eighths, on short early mine roads, to 2¼ x five-eighths,

except the state railways; the Norristown line, which at that

time used 40-pound rail; the Philadelphia and Reading, which used

45-pound rail; the York and Wrightsville; Buck Mountain; Little

Schuylkill and Susquehanna; Beaver Meadow extension; and West

Branch, a road leading from Schuylkill Haven to Mine Hill. All

the railways of Virginia, North and South Carolina, Georgia, and

Florida used flat bars, varying in dimensions from 2 x ½

to 2½ x ¾ except the South Carolina, and portions

of the Georgia and Central roads, of Georgia. All the railways

of Alabama, Louisiana, Mississippi, Tennessee, and Kentucky used

flat bars, except the Pontchartrain, of New Orleans; the Mississippi;

the Vicksburg and Jackson, and the Grand Gulf and Port Gibson.

All the railways of the Western states used iron bars or plates

except the Madison and Indianapolis.

WOODEN "RAILS," STRING PIECES, OR STRINGERS.

In a large proportion of the very early railroads wood was

extensively used of such shapes and patterns that, in the railway

language of that day, it was generally called "rails."

Some of the primitive lines did not even have these wooden rails

covered with flat iron bars, and they were called wooden rail-roads,

a term which was also frequently applied to the forms of construction

in which the wooden rail was plated with iron bars. Timber rails

were an article of commerce. Considerable quantities were sent

from South Carolina and North Carolina to be used on the early

railways in Pennsylvania. Their dimensions were sometimes 5 x

9; and sometimes 5 inches wide and 7 deep, and they were usually

plated with flat iron bars. The dimensions of these bars was frequently

a matter of considerable importance. When the bars were narrow

and thin it was found that under the pressure of heavy loads,

the bars would bend and sink into the wooden rail. To obviate

this effect, a small sheet of zinc was sometimes placed beneath

the ends of the iron rails. The wooden rails, string pieces, or

stringers, rested frequently on wooden ties which were then called

sleepers.

The following description of an early road of a class which,

while it did not represent the highest rank, was very much better

than a number of inferior roads, was published in 1832, in the

notes appended to Mr. G. W. Smith's American edition of Wood's

Treatise on Railroads. The account was furnished by Messrs. Kughler

and Dundas:—

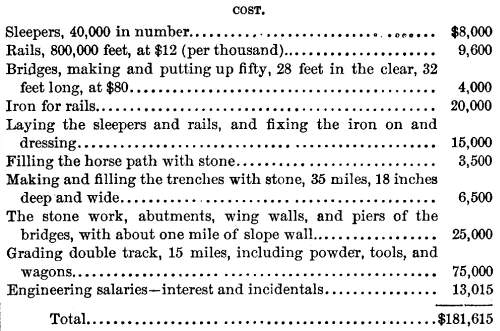

"The Mine Hill and Schuylkill Haven Railroad was begun in

June, 1829, and finished, the main line, in June, 1830, and the

remainder in June, 1831. The main line commences at Schuylkill

Haven, and extends 101 miles along the west branch of the river

Schuylkill, through the Mine Hill Gap. At the fork of this branch

with the west-west branch of the river, 6 miles from Schuylkill

Haven, a branch of the railroad extends along the last-mentioned

arm of the river, 3½ miles of a double track, and one mile

of a single track, but graded for a double track, making 14 miles

of a double track, and one of a single, or 15 miles in the whole.

The company have disbursed for all expenses, in completing this

work, $181,165. The width of the track is 4 feet 8½ inches.

The sleepers (white oak) are 4 feet apart, from centre

to centre, and average 10 x 8 inches. The wooden rails (white

oak) are 4 x 7 inches. The iron rails are 1½ inches wide

by half an inch thick. The curves are in no instance of a radius

less than 400 feet, but generally 500 feet. The grades do not

exceed 30 feet to the mile, except on two inclined planes, the

first of which is 80 feet to the mile; the second 150 feet to

the mile. The sleepers rest on stone rubble work, in three parallel

lines, from one end of the road to the other. There are 50 bridges,

each of 28-feet span. The highest embankment is 21 feet, and the

deepest excavation 31 feet. There are 12 culverts, and several

minor bridges and drains.

COST.

This is as near the actual cost as can be obtained."

It will be perceived that in this statement the wood on which

the iron rested was designated "rails," while the iron

with which they were plated was described as "iron for rails."

ORIGIN OF THE T-RAIL.

The imperfections of the snake-head rails and of the early

English substitutes for them suggested to an American, Mr. Robert

L. Stevens, of Hoboken, who was the son of Col. John Stevens,

the prominent early American advocate of railways, an improvement

in rail construction which is the progenitor of the present T-rail.

It is stated that when Mr. Robert L. Stevens, who was actively

identified with the construction of the Camden and Amboy Railroad,

"was on the ship, on his way to Europe to order the 'John

Bull,' in 1830, he devoted a considerable amount of time to whittling

out cross-sections of what be thought Would be a good kind of

iron rails to lay on the railroad. The best rail then known was

the T-rail without any base.

This style had been adopted by all the most important roads in

Europe. Owing to its peculiar shape, it required a chair on every

cross-tie or stone block, as the case might be. Stevens was the

first man to design the rail which he termed the H-rail—in

other words, a rail with a base which could be spiked with 'hook-headed'

spikes directly to the bearing." Rails made in accordance

with this pattern were laid down upon the Camden and Amboy when

it was first constructed, and methods were also adopted for joining

or splicing the rails which represent a great advance on the systems

then generally prevailing. Of these rails a report of the company

says that they were of the I form invented by Mr. Stevens,

3½ inches high, 2½ inches on the upper running surface,

and 3½ inches in width on its base, weighing 42 pounds

to the yard.

The writer has been credibly informed that Mr. Stevens encountered

great difficulty in his efforts to induce a British rail mill

to make rails of the improved pattern he had devised. He was obliged

to assume the whole responsibility of the scheme, to pay all the

extra expenses, and to give heavy security to guard the works

against all description of damages that could possibly be inflicted

on the rail Works by this innovation, which was evidently regarded

as dangerous, or at least highly imprudent, and likely to prove

disastrous to all concorned. The supposed grounds for such adverse

views must have made a deep impression, for it long period elapsed

before the use of T-rails became

approximately universal, although some companies adopted the T-rail a few years after it was first

used on the Camden and Amboy. The T-rail

became widely known as the Vignoles rail, rather than the Stevens

rail, because a European engineer, Mr. C. B. Vignoles, hastened

its introduction on European railways, using them on English roads

during the progress of construction to an extent that gave to

them the title of contractors' rails.

A recognition of the usefulness of the improvement must have

been comparatively rapid, because by or before 1840 the H- or T-rail

was in use on all or portions of the following American lines,

viz.: Camden and Amboy; Philadelphia and Reading; Philadelphia,

Wilmington and Baltimore; Long Island; portions of the Philadelphia

and Columbia Railroad, on which flat, plate, or bar-iron rails

had originally been laid; on important New England roads, including

the second track of the Boston and Lowell, Boston and Worcester,

Boston and Providence, Providence and Stonington; New Castle and

Frenchtown; Washington branch of the Baltimore and Ohio, and portions

of the Georgia Railroad.

In a description of the Camden and Amboy Railroad, contained

in Mr. George W. Smith's appendix to Wood's Treatise on Railroads,

and published in 1832, the following reference is made to the

T- or H-rails

used: "The rails are of rolled iron, 16 feet long, 2-one-eighth

inches wide on the top, 3¼ inches at the bottom and 3½

deep; the Dock half-inch thick. The weight is 209 pounds = 39-three-sixteenths

pounds per yard. They are secured by clamps of iron, riveted at

the extremity of each bar. The rails are attached to the stone

blocks and sleepers by means of nails or pins at the sides, driven

into wooden plugs. Chairs are dispensed with."

The following interesting letter relating to this subject is

published in Mr. J. M. Swank's census report of 1880, on iron

and steel manufactures, the writer of the letter being a nephew

of Mr. Robert L. Stevens:—

"HOBOKEN, NEW JERSEY, May 31, 1881.

DEAR SIR: In answer to your letter of the 27th instant 1 will

say that I have always believed that Robert L. Stevens was the

inventor of what is called the T-rail,

and also of the method of fastening it by spikes, and I have never

known his right to the invention questioned.

The rail of the Liverpool and Manchester Railroad, on its opening,

in September, 1830, was of wrought iron, divided into fish-bellied

sections, each section being supported by a cast-iron chair, to

which it was secured by a wooden wedge. The form was derived from

the old cast-iron fish-bellied train rail, cast in single sections,

each about 36 inches long. This wrought-iron rail was afterwards

improved by making its bottom straight uniformly throughout its

length.

Mr. Stevens' invention consisted in adding the broad flange

on the bottom, with a base sufficient to carry the load, and shaped

so that it could be secured to the wood below it by spikes with

hooked heads; thus dispensing with the cast-iron chair, and making

the rail and its fastenings such as it now is in common use. In

the year 1836 and frequently afterwards he spoke to me about his

invention of this rail, and told me that in London, after unsuccessful

applications elsewhere in England, shortly after the opening of

the Liverpool and Manchester Railroad, he had applied to Mr. Guest,

a member of Parliament, who had large rolling mills in Wales,

to take a contract to make his rail for the Camden and Amboy Railroad,

of which he was the chief engineer; that Mr. Guest wished to take

the contract, but considered that it would be impracticable to

roll the rail straight; that, finally, Mr. Guest agreed to go

to Wales with him and make a trial; that great difficulty was

at first experienced, as the rails coming from the rolls curled

like snakes, and distorted in every imaginable way; that, by perseverance,

the rail was finally successfully rolled; and that Mr. Guest took

the contract. The Camden and Amboy Railroad, laid with this rail,

was opened October 9th, 1832, two years after the opening of the

Liverpool and Manchester Railroad. Of this I was a witness.

This rail, long known as the old Camden and Amboy rail, differed

but little, either in shape or proportions, from the T-rail now in common use, but weighed

only 36 pounds to the yard. For the next six or eight years after

the opening of the Camden and Amboy Railroad this rail was but

little used here or abroad, nearly all the roads built in the

United States using the flat iron bar, about 2½ inches

by ¾ inch, nailed to wooden rails, and the English continuing

to use the chair and wedge.

My uncle always regretted that he had not patented his invention.

He mentioned to me, upwards of forty years ago, that when advised

by his friend, Mr. F. B. Ogden, the American consul at Liverpool,

who was familiar with the circumstances of his invention, to patent

it, he found that it was too late, and that his invention had

become public property.

Yours, truly,

FRANCIS B. STEVENS."

DIVERSITIES IN PERMANENT WAY.

In addition to the plans of construction heretofore referred

to, various modifications were adopted in different localities,

the most important of which were rendered possible by the T-or H-rail.

The Boston and Lowell used, in its first track, edge rails which

were not parallel, but of the fish-bellied pattern, i.e.,

their bottoms were slightly curved, as the body of a fish is curved,

so that the amount of iron used was greatest at the points most

distant from the rail joints. Where the H-

or T-rail was used numerous chairs

ceased to be indispensable, as this rail, unlike the edge rail,

was self-supporting, and the use of chairs was generally confined

to places where the rails were united. A greater number of sleepers

or ties than had originally been considered desirable were put

down in the tracks of some roads. On the Boston and Providence

sleepers of white cedar were laid down 3 feet apart from centre

to centre. They were seven feet long and six inches thick, and

rested on broader sills of hemlock. On the Philadelphia and Reading,

on which H-rails, weighing 45-one-eighth

pounds per yard were used, the rails were laid upon white oak

sleepers, or cross-ties, seven feet in length, and of a uniform

depth or thickness of seven inches. They were laid 3½ feet

apart from centre to centre, and each sleeper was laid upon a

prism of broken stone, deposited in a trench 14 inches deep, 12

inches wide, and 9 feet long across the line of the track. At

the rail joints the rails rested upon cast-iron chairs, let into

the sleepers by means of notches cut for that purpose. The chair

was six inches square at its lower surface, where it was five-eighths

of an inch in thickness. There were bolts, with nut screws attached,

to hold the ends of the two rails to the chair. The bolt and nut

weighed 7 ounces, and the chair 10½ pounds. The chairs,

and the rails, at the points where they rested on sleepers, were

spiked down, with spikes six inches in length, with stems three-fourths

by five-eighths of an inch. In a mile of track of the Philadelphia

and Reading, built in accordance with these requirements, there

were 563 bars of iron, weighing 71 tons; 563 chairs, weighing

5,910 pounds; 7,882 spikes, weighing 4,524 pounds; 1,126 screw

bolts and nuts, weighing 481 pounds, and 1,689 sleepers. The entire

cost of the single track as laid, was reported to be $7,617 per

mile. As the road was intended, from the outset, for exceptionally

heavy traffic, it was much more substantially built, in every

respect, than was usual at the time of its construction, and the

rails proved to be very serviceable.

On portions of the Western (of Massachusetts), which were being

constructed about 1840, a mode was adopted which differs in some

important respects from any of those heretofore described. The

rails were of the U or bridge

pattern. A contemporaneous description says: "The rails are

of wrought iron, rolled in lengths of fifteen feet, and made hollow.

The top is two inches wide, base six inches, and height one inch

and three-quarters. Holes are punctured in the flanges on both

sides, about eighteen inches apart, to secure the rail (without

chairs) to the sleepers, by means of screws eight inches long.

To prevent the sleepers from spreading, there are, at every fifteen

feet, iron ties across the railway, spiked down at each end of

the sleepers."

In this description the term sleepers was used to designate

"longitudinal, continuous sleepers of Memal timber kyanized,

thirteen or fourteen inches wide, by six and a half or seven inches

thick, which are firmly bedded on the ground, previously made

even and well rammed. On the top of the sleepers are laid the

rails." Another feature was an effort to give the outer edge

of the rail a slightly higher altitude than the inner edge, for

the purpose of making the surface of the rail correspond as closely

as possible with the conical shape of the car wheels. Other railways

endeavored to accomplish that object at comparatively early periods,

but the results were usually not satisfactory.

Transport Systems

| Antebellum RR | Contents

Page

|