The Evolution of the American

Locomotive.

Scientific American Supplement—May

8, 1897 (Part 3 of 3)

By HERBERT T. WALKER.

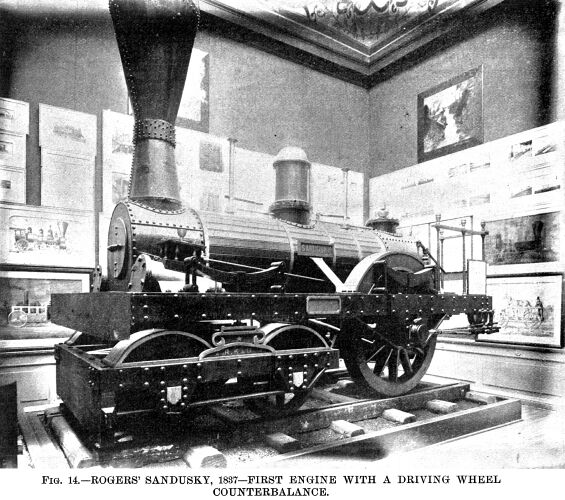

FIG. 14

illustrates the Sandusky, the first locomotive built at the famous

Rogers Locomotive Works, Paterson, N. J. At that time the name

of the firm was Rogers, Ketchum & Grosvenor, and its founder

Thomas Rogers, designed this engine. The late Zerah Colburn remarked

that "Thomas Rogers maybe fairly said to have done more for

the modern American locomotive than any of his contemporaries." FIG. 14

illustrates the Sandusky, the first locomotive built at the famous

Rogers Locomotive Works, Paterson, N. J. At that time the name

of the firm was Rogers, Ketchum & Grosvenor, and its founder

Thomas Rogers, designed this engine. The late Zerah Colburn remarked

that "Thomas Rogers maybe fairly said to have done more for

the modern American locomotive than any of his contemporaries."

The Sandusky ran its trial trip from Paterson to Jersey City

and New Brunswick and back October 6, 1837, its performance being

entirely satisfactory. It was intended for the New Jersey Railroad

and Transportation Company, but was, however, bought for the Mad

River and Lake Erie Railroad by its president, Mr. J. H. James,

of Urbana, O. It continued in service many years. The cylinders

were 11 in. in diameter by 16 in. stroke. Driving wheels 4 ft.

6 in. diameter; truck wheels 2 ft. 6 in. diameter. The general

design did not differ materially from the Experiment (Fig 11),

but it is of interest as being the first locomotive with weights

on the driving wheels to counterbalance the cranks and connecting

rods. For this Mr. Rogers filed a specification in the Patent

Office dated July 12,1837, in which he says, "The irregular

motion which arises from not having the cranks and connecting

rods balanced is attended with much injury to the engine and to

the road, and with much loss of power." The driving wheels

were of cast iron, with hollow spokes and rims, which at that

time was a remarkable novelty. The section of the spokes was of

oval form, and the rim of very much the same shape as that which

is in common use to-day. In order to counterbalance the parts

referred to, the rim of the wheel opposite the crank was cast

solid. The importance of counterbalancing was not recognized until

several years after it had been introduced by Mr. Rogers, but

to-day it would be hard to find a locomotive without counterbalanced

driving wheels.

Another sporadic form of locomotive engine was built by Gillingham

& Winans, of Baltimore, for the Baltimore and Ohio Railroad,

in the year 1838. They had upright boilers, but the cylinders

were horizontal and were connected to cranks on an intermediate

shaft, which was geared to a second shaft having outside cranks

to which the four driving wheels were coupled. These engines were

of ungainly form and were nicknamed "crabs," but in

the year 1844 Mr. Winans brought out another class of engine retaining

substantially the same system of gearing but with eight coupled

wheels instead of four, and a horizontal boiler. These engines

were ignominiously named "mud diggers," but they did

heavy freight service on the Baltimore and Ohio Railroad for many

years.

At this period it will be necessary to revisit England to see

what was going on in the shops of Robert Stephenson & Company,

Newcastle upon Tyne, in 1842. In that year it appears that the

link motion was reinvented without previous knowledge of James’

invention. William Howe, a mechanic employed in Stephenson’s

shops, decided to place a curved link between the eccentric rods

to take the place of the Stephenson "fork motion," then

in general use. He made a pencil sketch and wooden model which

were shown to Robert Stephenson, who, seeing its merits, ordered

it to be fitted to all engines constructed at his works, and from

that time it has been known as "Stephenson’s link motion."

The first engine equipped with this gear was No. 71, for the North

Midland Railway, and commenced to run September 10, 1842. There

was a dispute between Howe and an apprentice named Williams, who

claimed to have a share in the invention, but as we have not space

to enter into the details of the controversy, the reader is referred

to Colburn’s "Locomotive Engineering," where the

matter is very ably dealt with.

But not even when the link was being used with such remarkable

success in England did American engineers recognize its merits,

and it was not until 1847 that it was adopted in this country.

In the year 1849 Mr. Thomas Rogers introduced it in his practice,

fitting a stationary link motion to some engines for the Hudson

River Railroad. In this arrangement the curve of the link was

convex toward the eccentrics, instead of concave, as in the Stephenson

gear, and the link was suspended on a fixed center, the valve

rod block being moved up and down instead of the link. This plan

was introduced by Sir Daniel Gooch, master mechanic of the Great

Western Railway, of England, about the year 1845. In 1850 Mr.

Rogers commenced to build engines with the shifting link motion,

and soon afterward it came into general use. Other builders, however,

strenuously resisted the innovation, and none more so than Mr.

Baldwin, who could not be induced to adopt it until the year 1854,

when he fitted the link to the Pennsylvania, an engine for the

Central Railroad of Georgia.

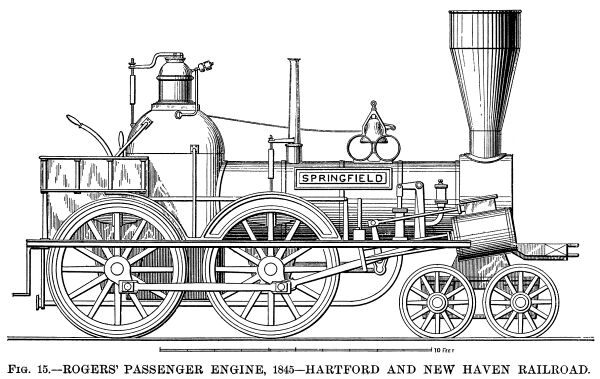

The next example

of progress in locomotive construction is illustrated in Fig.

15, which shows a very good engine designed by Mr. Rogers

and built at his works, in 1845, for the Hartford and New Haven

Railroad. It had equalizing levers between the driving wheel springs,

which do not show in the drawing. The truck had side bearings

and springs on the sides of truck. The pumps had short stroke

and were worked from the crosshead as shown. The cylinders were

11½ in. diameter by 18 in. stroke. Driving wheels 5 ft.

diameter. We notice the supplemental frame that supports the running

board. It illustrates the transition from outside to inside framing.

The frames were of bar iron and the reversing gear was the hook

or fork motion. The next example

of progress in locomotive construction is illustrated in Fig.

15, which shows a very good engine designed by Mr. Rogers

and built at his works, in 1845, for the Hartford and New Haven

Railroad. It had equalizing levers between the driving wheel springs,

which do not show in the drawing. The truck had side bearings

and springs on the sides of truck. The pumps had short stroke

and were worked from the crosshead as shown. The cylinders were

11½ in. diameter by 18 in. stroke. Driving wheels 5 ft.

diameter. We notice the supplemental frame that supports the running

board. It illustrates the transition from outside to inside framing.

The frames were of bar iron and the reversing gear was the hook

or fork motion.

The writer has not succeeded in discovering when the first

sand boxes were used. The early locomotives were without them.

When the engine slipped, the fireman jumped down and threw some

gravel on the rails with his shovel, or, failing that, he used

the pinchbar, with verbal encouragements, more powerful than polite,

from the engine driver. The next step appears to have been a bucket

of sand carried on the foot board, and scattered by hand when

required. Mr. Baldwin commenced to place sand boxes on his engines

in the year 1846 for the Philadelphia and Reading Railroad. The

chief objection to sand is that, while it prevents the driving

wheels from slipping, it has a retarding effect on the train wheels,

which, with a heavy load on a hill, is a very serious drawback.

To overcome this, a jet of steam or water has been tried, and

with a measure of success, as it is well known that thoroghly

wet rails will give almost as good adhesion as when they are perfectly

dry. An electric current has been passed through the driving wheels

and rails to prevent slipping; but none of these devices are equal

to good dry sand.

In the year 1846, Septimus Norris, a brother of William Norris,

patented a ten wheel freight engine with six driving wheels combined

with a leading truck. Several of these were built for the Philadelphia

and Reading Railroad.

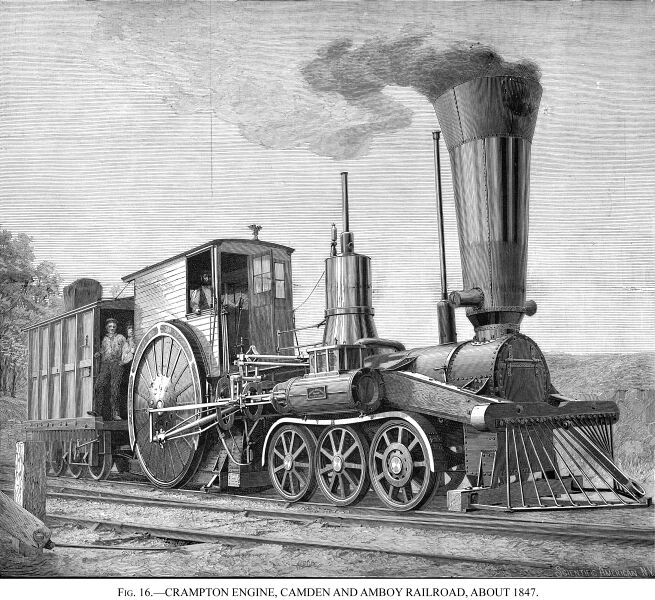

An interesting locomotive is illustrated by Fig. 16,

which shows one of a class built at the Norris Works about the

year 1847, for the Camden and Amboy Railroad. There were several

of these engines built, most of them having driving wheels 8 ft.

in diameter and cylinders variously 13 in. by 34 in., 13 in. by

38 in. and 14 in. by 38 in. stroke. Their weight was about 22

tons in working trim. This type of engine has the driving wheels

behind the firebox and is known as the "Crampton" class,

having been patented in 1843 by the late Thomas Russell Crampton,

an English engineer of some distinction. He did not, however,

originate the idea, as Baldwin built engines with the driving

wheels behind the firebox in the year 1833. The advocates of this

class of engine claimed that it admitted of driving wheels of

practically unlimited diameter, while the boiler could be dropped

down to the axles of the carrying wheels, thus enabling an engine

with large driving wheels to have a low center of gravity, which

was at that time and for years afterward considered necessary

for safety at high speeds. Crampton engines never came into general

use anywhere except in France, where the "système

Crampton" was very popular and it is believed that some of

the engines are still running.

Referring to the example before us (Fig. 16), we are

informed that these engines made steam slowly, which was probably

caused by the fact that the boilers were small compared with the

immense cylinders and driving wheels. Another drawback to them

was that they lacked adhesive weight, having only about 8 tons

on the driving wheels; it was, therefore, hard to start them with

a train, although when under headway they occasionally covered

a mile in 53 seconds. But the most serious objection to there

was their tendency to run off the track when traveling fast, the

chief reason being that the propelling mechanism at the rear end,

with unbalanced driving wheels, caused the front end to "nose"

or oscillate laterally. It will be observed that the driving wheels

had a wood filling between the spokes to prevent "raising

dust."

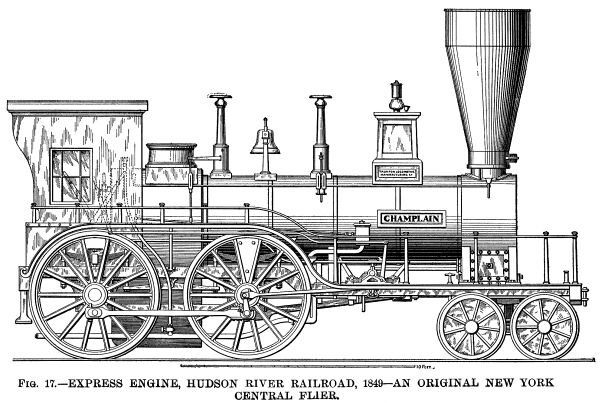

Fig. 17 illustrates a fine engine designed by Mr. McQueen

for the Hudson River Railroad (now apart of the New York Central

and Hudson River Railroad). It is interesting not only for the

excellence of the design, but because it was one of the first

engines to do regular everyday express work on the road that now

claims to have the fastest regular train in the world. It appears

that the Hudson River steamboats, even as far back as 1845, offered

great inducements to travelers by reason of their luxurious accommodation

and high speeds, and these express trains were put on to compete

with them. A writer in the Practical  Mechanic’s Journal of 1850-51, in describing this

engine, said: "The usual speed of railroads was not so much

greater as to induce the passengers to leave the magnificent floating

palaces. Great speed must, therefore, be determined on."

The result was the Champlain, which commenced working the express

trains between Thirty-first Street, New York, and Poughkeepsie,

72 miles, in December, 1849. The distance was covered in 2 hours

25 minutes = 29.79 miles an hour, including twelve stops. The

weight of the trains averaged 94 tons, exclusive of engine and

tender. The ordinary trains did the same distance in 2 hours 45

minutes. Mechanic’s Journal of 1850-51, in describing this

engine, said: "The usual speed of railroads was not so much

greater as to induce the passengers to leave the magnificent floating

palaces. Great speed must, therefore, be determined on."

The result was the Champlain, which commenced working the express

trains between Thirty-first Street, New York, and Poughkeepsie,

72 miles, in December, 1849. The distance was covered in 2 hours

25 minutes = 29.79 miles an hour, including twelve stops. The

weight of the trains averaged 94 tons, exclusive of engine and

tender. The ordinary trains did the same distance in 2 hours 45

minutes.

The Champlain had cylinders 15 in. in diameter by 20 in. stroke.

Steam ports, 14 in. by 1 in. Exhaust port, 14 in. by 2 in. Driving

wheels, 5 ft. 6 in. in diameter. Heating surface of firebox, 79.43

sq. ft.; of tubes, 824.43 sq. ft.; total heating surface, 903.86

sq. ft. Gross weight of engine, 23½ tons. The frame was

a curious example of the transition from plate to bar, it being

made of two plates with a square bar riveted between. The plates

were 5 inches deep.

There were two slide valves in. the steam chest; the upper

one was a cut-off valve to enable the steam to be worked expansively,

and it moved on a fixed perforated plate immediately over the

main valve. The former was worked from a return crank on the crank-pin;

the main valve was worked from the eccentrics with the V hook motion commonly used at that period.

The throw of the main valve was 3½ in. with five-eighths

in. lap, and set with a lead of three-sixteenths in. The expansion

valve cut off at half stroke.

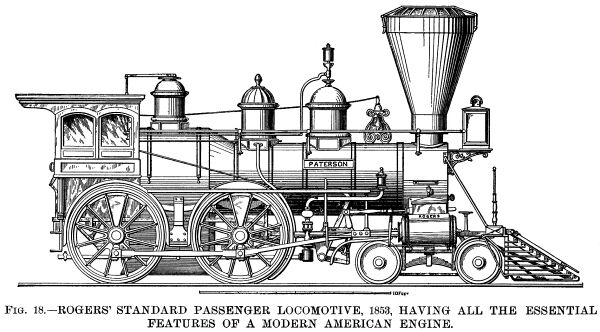

Referring back

to Fig. 12, it will be seen that Campbell’s engine,

although it has the Stephenson firebox, four coupled driving wheels,

with cylinders connected to the forward pair, and a leading truck,

does not possess all the essential features of the modern locomotive,

because the frames are outside and of plate iron and wood. The

cylinders are inside connected, and it has no equalizers. Fig.

13 has outside cylinders, leading truck, inside frames and

equalizers, but the frames are of plate iron and wood, the cylinders

are connected to the rear driving wheels, and the firebox is of

the Bury pattern Fig. 15 has the bar frame, and begins

to look more like an American engine, having the equalizers and

the cylinders connected to the, forward driving wheels; but the

cylinders are inclined, and the outside frame for the running

board and objectionable Bury firebox are still retained, and the

reversing gear is the hook motion. Engineers up to that time were

afraid of spreading the truck wheels too far apart; hence the

necessity of inclined cylinders but in 1850 Mr. Rogers designed

a spread truck, which permitted the cylinders to be dropped down

to a horizontal line, and in the same year the wagon top boiler

was introduced in the practice of the Rogers Locomotive Works;

and so we have in the year 1853 an engine possessing all the essential

features of a modern American locomotive, which is shown in Fig.

18. It had the Stephenson firebox, with the peculiar inclined

or tapered joint between it and the barrel of the boiler, making

what is known as the wagon top boiler. The latter was an American

invention. A large number of these engines were built by Mr. Rogers

for various railroads. They had the link motion. The cylinders

were 16 in. diameter by 22 in. stroke, and the driving wheels

were 5 ft. in diameter, although the size of the latter was varied

in different engines. Referring back

to Fig. 12, it will be seen that Campbell’s engine,

although it has the Stephenson firebox, four coupled driving wheels,

with cylinders connected to the forward pair, and a leading truck,

does not possess all the essential features of the modern locomotive,

because the frames are outside and of plate iron and wood. The

cylinders are inside connected, and it has no equalizers. Fig.

13 has outside cylinders, leading truck, inside frames and

equalizers, but the frames are of plate iron and wood, the cylinders

are connected to the rear driving wheels, and the firebox is of

the Bury pattern Fig. 15 has the bar frame, and begins

to look more like an American engine, having the equalizers and

the cylinders connected to the, forward driving wheels; but the

cylinders are inclined, and the outside frame for the running

board and objectionable Bury firebox are still retained, and the

reversing gear is the hook motion. Engineers up to that time were

afraid of spreading the truck wheels too far apart; hence the

necessity of inclined cylinders but in 1850 Mr. Rogers designed

a spread truck, which permitted the cylinders to be dropped down

to a horizontal line, and in the same year the wagon top boiler

was introduced in the practice of the Rogers Locomotive Works;

and so we have in the year 1853 an engine possessing all the essential

features of a modern American locomotive, which is shown in Fig.

18. It had the Stephenson firebox, with the peculiar inclined

or tapered joint between it and the barrel of the boiler, making

what is known as the wagon top boiler. The latter was an American

invention. A large number of these engines were built by Mr. Rogers

for various railroads. They had the link motion. The cylinders

were 16 in. diameter by 22 in. stroke, and the driving wheels

were 5 ft. in diameter, although the size of the latter was varied

in different engines.

In 1857 Mr. Bissell patented a four wheeled truck, having its

frame extended rearwardly and pivoted to the engine frame. The

truck, therefore, swung from this pivot instead of on a central

pin, and the engine rested on a pair of V shaped inclined

planes  midway between

the two axles. The inventor claimed that a truck on his plan adjusted

itself to the curvature of the track better than one of the ordinary

plan. Mr. Hudson, of the Rogers Locomotive Works, was one of the

first to recognize the value of Bissell’s invention, and

applied it to a locomotive in 1858. In the same year Bissell patented

the single axle or pony truck, as it is often called. This was

constructed on substantially the same principle as his four wheeled

truck and is now in common use. midway between

the two axles. The inventor claimed that a truck on his plan adjusted

itself to the curvature of the track better than one of the ordinary

plan. Mr. Hudson, of the Rogers Locomotive Works, was one of the

first to recognize the value of Bissell’s invention, and

applied it to a locomotive in 1858. In the same year Bissell patented

the single axle or pony truck, as it is often called. This was

constructed on substantially the same principle as his four wheeled

truck and is now in common use.

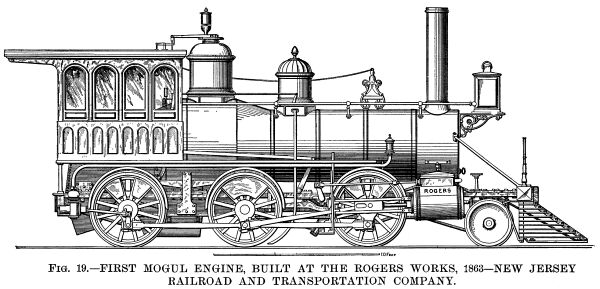

On the death of Mr. Rogers, which occurred in 1856, the business

of Rogers, Ketchum & Grosvenor was reorganized under the title

of the Rogers Locomotive and Machine Works, and Mr. William S.

Hudson was appointed superintendent. Mr. Hudson was a pupil of

George Stephenson’s, and was one of the foremost locomotive

engineers of his day. Under his supervision, the first Mogul engine,

Fig. 19, built at the Rogers works, was completed in 1863

for the New Jersey Railroad and Transportation Company, now the

New Jersey part of the Pennsylvania Railroad. This engine had

six coupled wheels and the Bissell pony truck previously described,

with swing links patented by Mr. Alba F. Smith, and also an equalizing

lever from the truck to the springs of the forward driving wheels.

This equalizing arrangement was invented and patented by Mr. Hudson.

The cylinders were 17 in. diameter by 22 in. stroke. Driving wheels

4 ft. 6 in. in diameter. Weight about 35 tons. A very large proportion

of the weight of a Mogul engine rests on the driving wheels, which

makes it the most useful and popular freight engine of to-day.

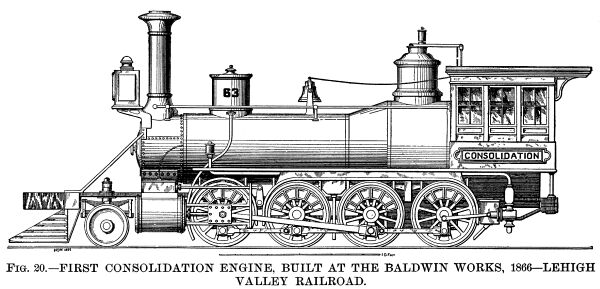

The rapid increase of traffic during the period under notice

demanded a still more powerful freight engine, and in order to

secure the necessary amount of adhesion, Mr. Alexander Mitchell,

master mechanic of the Lehigh and Mahoning Railroad, designed

in the year 1866 an eight coupled engine, and it was named Consolidation.

This name was suggested by the consolidation of the Lehigh and

Mahoning with the Lehigh Valley Railroad, which had just then

been consummated.

This historical

locomotive is shown in Fig. 20, and it is interesting to

note that both the Mogul and Consolidation engines of the present

day have not been altered in any essential particular except in

dimensions, which reflects great credit on their designers. The

Consolidation was built at the Baldwin Locomotive Works, and its

principal dimensions were: Cylinders, 20 in. diameter by 24 in.

stroke; driving wheels, 48½ in. in diameter. The pony truck

was equalized with the front driving wheels. Weight about 45 tons.

The boiler was fed by one injector and two feed pumps; the latter

were worked by return cranks on the rear driving wheels, as shown.

Pumps have now practically become obsolete. They gave much trouble

by freezing in cold weather, and many vexatious delays were caused

by "failure of the pumps." This historical

locomotive is shown in Fig. 20, and it is interesting to

note that both the Mogul and Consolidation engines of the present

day have not been altered in any essential particular except in

dimensions, which reflects great credit on their designers. The

Consolidation was built at the Baldwin Locomotive Works, and its

principal dimensions were: Cylinders, 20 in. diameter by 24 in.

stroke; driving wheels, 48½ in. in diameter. The pony truck

was equalized with the front driving wheels. Weight about 45 tons.

The boiler was fed by one injector and two feed pumps; the latter

were worked by return cranks on the rear driving wheels, as shown.

Pumps have now practically become obsolete. They gave much trouble

by freezing in cold weather, and many vexatious delays were caused

by "failure of the pumps."

Mr. H. J. Giffard, a French engineer, discovered that the motion

imparted by a jet of steam to a surrounding column of water was

sufficient to force it into the boiler from which the steam was

taken. In July, 1858, he patented his invention of the injector,

and the various inspirators now in general use for supplying steam

boilers with water are all constructed on the model of the Giffard

injector.

In these days of "continuous brakes," it seems remarkable

that the early locomotives were absolutely without any retarding

mechanism; and even down to the medieval period of railway history,

the fastest English trains were run with only a hand brake on

the tender, and a similar brake, worked by the guard, in the brake

van. When the tender weighed only 10 or 15 tons and the brake

van less, this system was woefully inadequate, and many frightful

accidents resulted. American trains were far better equipped in

this respect, and at a very early period all our cars, both freight

and passenger, were provided with hand brakes. In the year 1833,

Robert Stephenson patented a steam brake for locomotive engines,

and in the following year the device was applied to an engine

on the Liverpool and Manchester Railway. It was successful, but,

like the link motion, never came into general use until years

afterward, when the so-called "steam driver brake" was

introduced, being substantially the same as Stephenson’s

design of 1833.

As we have not space to examine the numerous forms of power

brakes that have come and gone during the last fifty years, it

will suffice to say that the invention of continuous brakes, which

act on all the wheels of the train simultaneously, is the most

important one of modern times, inasmuch as their adoption has

not only rendered possible the present high speeds, but has done

more in the way of saving life and property than any other invention

connected with railways.

Various systems of steam, hydraulic and vacuum brakes have

been tried, and also brakes applied by the inertia of the moving

train with more or less success, but it appears that brakes worked

by air pressure are the most efficient and reliable.

George Westinghouse, Jr., introduced his continuous air brake

in 1869 upon a train on the Pittsburgh, Cincinnati, Chicago and

St. Louis Railway running out of Pittsburgh. The brake was non-automatic,

but in 1873 he made a very important improvement by placing his

automatic brake on the Reading Railway. In this arrangement all

the brakes are automatically applied if the train parts or any

of the cars run off the rails. The original automatic system has,

however, been supplanted by the quick action automatic brake,

introduced by Mr. Westinghouse in 1886, which makes the use of

air brakes possible on long freight trains, so that a train of

50 standard freight cars, having a total weight of nearly 2,000,000

pounds, measuring over 1,900 feet in length and traveling at the

rate of 37 miles an hour on a level, can be stopped in the remarkably

short time of 15 seconds without skidding the wheels. In a separate

test to show the rapidity of application, it was found that the

brakes went fully on within two seconds from the tune the engine

driver opened his brake valve. This system is undoubtedly the

best in the world, and does great credit to Mr. Westinghouse.

It now only remains to glance at a few locomotives of modern

construction, as there is practically no difference between the

engines of to-day and those already described, except in dimensions

and weight.

As in 1836 it was found necessary to build four coupled engines

for heavy freight service, so, about fifteen years ago, six coupled

engines for heavy passenger service came into the field, and it

is a noteworthy fact that the fastest speed ever recorded was

attained by a six coupled passenger engine, No. 564, on the Lake

Shore and Michigan Southern Railway, October 24, 1895, when a

special train, weighing 304,500 lb., was conveyed from Erie to

Buffalo Creek (86 miles) in 1 hour 10 minutes 46 seconds = 72.92

miles an hour. During this trip 33 consecutive miles were made

at the rate of 80.6 miles an hour, 8 miles at 85.44 miles an hour,

and 1 mile was covered at the rate of 92.3 miles an hour. This

engine weighs 56½, tons, it has a leading four wheeled

truck, the cylinders are 17 in. in diameter by 24 in. stroke,

and six driving wheels, 5 ft. 6 in. in diameter, which, at 92.3

miles an hour, would make 469 revolutions per minute. The engine

was built by the Brooks Locomotive Works, Dunkirk, N. Y.

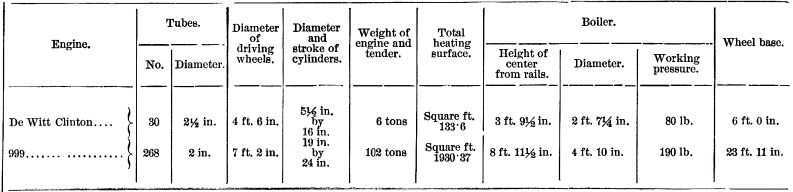

The left hand portion of Fig. 5 shows the celebrated

"999," on the New York Central and Hudson River Railroad.

It is the latest development of the American eight wheeled locomotive,

and the picture gives a good idea of the grandeur and beauty of

its proportions, when compared with the De Witt Clinton. It was

designed by Mr. William Buchanan, chief of motive power of the

above named railroad. The center line of the boiler is no less

than 8 ft. 11½ in. from the rails, and it is remarkably

steady at the highest speeds.

The Empire State Express covers 440 miles in 8¼ hours

= 53.33 miles per hour, including four stops, and this engine

hauls the train over a portion of the route. It was exhibited

with the De Witt Clinton at the Columbian Exposition, and a comparative

table of the dimensions of the first and latest New York Central

engines will be of interest.

This article would be incomplete without touching on "compound"

locomotives. To those who are not familiar with the subject, it

will be well to explain that in ordinary or "simple"

engines, the steam, after having done its work in the cylinders,

is released through the exhaust pipe into the chimney; but in

a compound engine, the steam from the boiler is admitted to one

cylinder only, called the "high pressure" cylinder,

and at the end of the stroke is exhausted to the next cylinder,

called the "low pressure" cylinder, and from thence

through the exhaust pipe to the chimney in the usual way. The

steam is thus made to do its work twice over by virtue of its

expansive force. Broadly speaking, compound locomotives may be

divided into three classes, viz., those having two, three and

four cylinders. Some very good two cylinder compounds have been

built by the Richmond Locomotive Works, which show an economy

of fuel consumption of about 25 per cent. A fine two cylinder

compound engine, No. 1 may be seen every day working in the Grand

Central Station yards in this city. It was designed by Mr. William

Buchanan, and is doing good service. A large number of tree cylinder

compounds are running on the London and Northwestern Railway,

of England, designed by the locomotive superintendent of that

line, Mr. F. W. Webb. These engines show a saving of fuel of about

25 per cent.

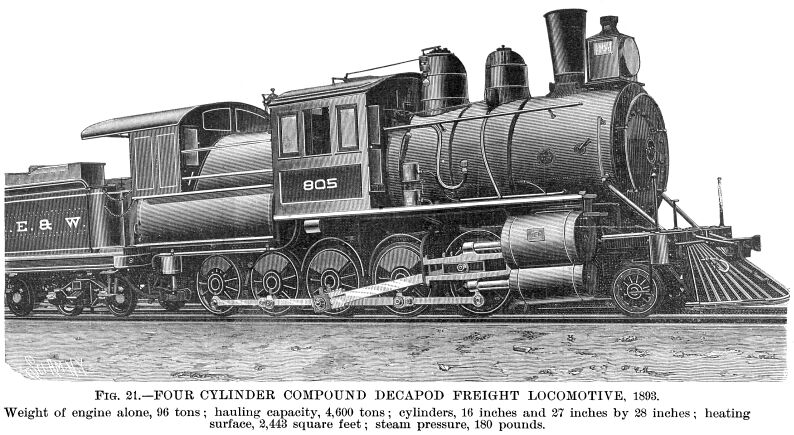

Fig. 21 illustrates one of the best examples of a four

cylinder compound locomotive. It is of the Vauclain type, and

was built by the Baldwin Locomotive Works for the New York, Lake

Erie and Western Railroad for heavy freight service.

The cylinders are arranged in pairs, the piston rods engaging

a common crosshead. The cylinders are 16 in. and 27 in. in diameter

by 28 in. stroke. The engine alone weighs 96 tons and has a hauling

capacity of 4,600 tons on a level. It is worth while to compare

this with the load drawn by the first Baldwin engine, Fig.

10.

It may be remarked that engineers are much at variance on the

question of compound locomotives; many men of the highest standing,

while admitting that a certain success has been attained by compound

engines, maintain that the economy in fuel is counterbalanced

by the disadvantages inherent to the greater complication of machinery

and by the extra cost for repairs. Notwithstanding this, it seems

probable that the compound engine is the locomotive of the future,

and that of the two cylinder type, as being the least complicated

and costly.

The writer takes pleasure in thanking Mr. J. Elfreth Watkins,

curator of the National Museum, Washington; Mr. Theo. N. Ely,

chief of motive power of the Pennsylvania Railroad; Mr. R. S.

Hughes, president of the Rogers Locomotive Company; Mr. William

Buchanan, chief of motive power of the New York Central and Hudson

River Railroad; the Baldwin Locomotive Works; the Westinghouse

Air Brake Company; Mr. M. N. Forney, M.E.; and Mr. Clement E.

Stretton, C.E., of Leicester, England, for the valuable data and

drawings they have kindly placed at his disposal.

Antebellum RR

| Contents Page

|