|

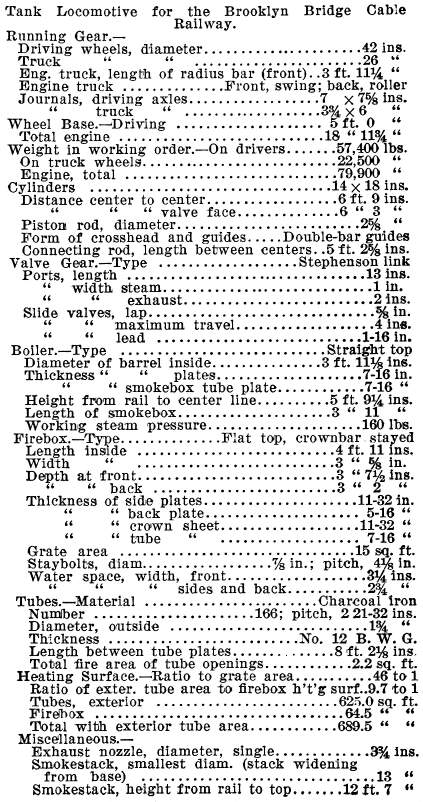

TANK LOCOMOTIVES FOR THE BROOKLYN BRIDGE.

Engineering News, June 13, 1895

On the Brooklyn Bridge cable railway tank locomotives are used

for switching the trains from the incoming to the outgoing tracks,

and also for hauling the trains at night (from 1 a. m. to 5 a.m.),

when the cable driving plant is stopped for inspection and overhauling.

For about ten years all the engines were of the four-wheel type,

with saddle tanks, the weight increasing from 10 tons in 1883

to about 22 tons in 1893, and six of these heavier engines are

still in use, As these engines had 33-in. wheels and 6 ft. wheel-base,

and rapidly wore out the rails and wheels at the switches and

the extremely sharp curves (100 ft. radius) over which they have

to pass, and as it required two of the engines to haul a; train

of three cars over the bridge (the maximum grade being 3¾),

it was decided to try a heavier and more powerful engine. A "double-end"

type was adopted, and the first was built in 1893 by the Baldwin

Locomotive Works (Eng. News, Dec. 7, 1893). It has four 42-in.

driving wheels, with 5 ft. driving wheel-base, and has a pony

truck at each end, making the total wheel-base 17 ft. 7 ins. The

weight is 68,000 lbs., with 53,000 lbs. on the driving wheels.

On dry rails and under favorable conditions of track it can haul

a train of four partially, or three fully, loaded cars up the

maximum grade at the speed of the cable trains, or 10.3 miles

per hour, this load being equivalent to about 85 to 100 tons,

the heaviest cars weighing 20 tons empty.

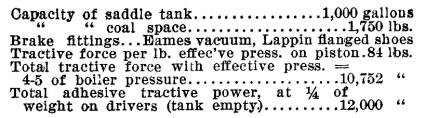

Two more engines of the same type, but somewhat larger and

heavier, have recently been built by H. K. Porter & Co., of

Pittsburgh, Pa., and one of these is shown in the accompanying

cut., These engines can haul six empty cars or four loaded cars

in regular service. The bank capacity is increased by extending

the saddle tank over the smoke-box, and the smokestack is made

wider at the top than at the base, instead of being a cylindrical

stack, as in the other engines. The engine is fitted with the

vacuum brake, the same as the cars, and the Lappin flange-bearing

brake-shoes of 50% hardness are used. The driving wheel tires

are 3 ins. thick, and the truck wheel tires 2½ ins. thick,

all 5½ ins. wide and flanged. The coiled bearing springs

were specified to be of 7/8 in. rods, and the flat springs to

have not less than 14 leaves 3½ ins. wide for the, driving

wheels and 8 leaves 2¼ ins. wide for the trucks. The three

spark arrester plates are 1/8-in. thick, with holes 1½

x 3-16 in., and there is also a steel wire netting. The feed is

supplied by a Korting injector and a force pump, each capable

of supplying the full amount of water. A boiler compound pot is

also attached, and lubrication is provided for by two Detroit

automatic sight-feed lubricators in the cab. The discharge from

the brake ejector is muffled, two 2½-in. Coale mufflers

being fitted.

The specifications make the following provisions as to quality

and tests of material: Boiler plates to be of open-hearth steel,

with a tensile strength (unannealed) of 55,000 to 65,000 lbs.

per sq. in., and an elongation of not less than 20% in 8 ins.

Stay-bolt iron to be capable of bending double both ways without

crack or flaw. The tubes to be rolled strictly to gauge throughout

their length, to show a perfect weld, be free from pitholes and

other imperfections, and to be expanded when fitted into place

without crack or flaw, while a 2-in. length must withstand flatting

closely down under the hammer without appearance of fracture.

The iron for stay-bolts and tubes must have a tensile strength

of 50,000 lbs. per sq. in., and an elongation of 25% in 8 ins.

The flues to be tested with a hydraulic pressure of 500 lbs. per

sq. in., and copper and brass pipes 300 lbs. per sq. in. Springs

to be oil tempered, and to sustain without set a weight equal

to 1½ times the extreme working load. The boiler to be

subjected to a test of 240 lbs. per sq. in. by hydraulic pressure,

and 185 lbs. per sq. in. under its own steam. We give below, in

our standard form, the list of dimensions and particulars of the

engine:

Brooklyn Bridge | Bridge Page

| Contents Page

|