BUILDING OF AMERICAN LOCOMOTIVES.—I.

Scientific American—June 7, 1902

It would be difficult to find a form of mechanical construction

in America which bears more strongly the imprint of our national

characteristics than the American locomotive. In its general appearance,

constructive details, and unquestionable convenience of operation,

it stands entirely distinct as a type among the hundred-and-one

styles of locomotives that are manufactured in the shops of the

world. This national individuality is seen even more strongly

in the great industrial establishments in which our locomotives

are made, where labor-saving machinery and carefully-thought-out

methods of shop management have enabled us to build at a speed

and price which cannot be approached by any other nation. The

magnitude of the locomotive industry in this country was emphasized

in the festivities which attended the recent completion of their

20,000th locomotive by one of the locomotive works of this country,

an event which occurred in the spring of the present year. The

early founding of the Baldwin Locomotive Works, its rapid growth,

the many standard types of locomotives which have been originated

in the shops of the company, and the fact that its locomotives

have been for years finding their way to the four corners of the

earth render the works thoroughly representative of the locomotive

industry in this country.

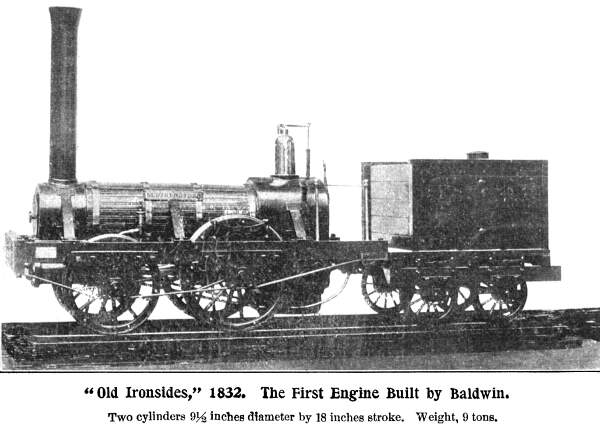

Mathias W. Baldwin, who founded

the establishment, started in business as a jeweler in a small

shop in Philadelphia in the year 1819. In 1830 the steam railroad

was beginning to make its appearance and establishing itself in

this country, and to gratify public interest the proprietor of

a Philadelphia museum gave an order to Baldwin for the construction

of a miniature locomotive for exhibition. In the spring of 1831

the work was completed and the toy was set in motion on a circular

railroad track at the museum. The success of the model brought

an order to Baldwin for a locomotive from the Philadelphia, Germantown

& Norristown Railroad Company. Guided by his experience with

the little model, and by some memoranda which he had taken of

a locomotive recently imported from England by the Camden &

Amboy Railroad Company, Baldwin completed the curious and historical

locomotive known as "Old Ironsides," of which we give

an illustration on our front page. The engine was tried November

23, 1832, and did duty on the Germantown road and, later, on other

roads for a period of over twenty years. The "Ironsides"

was a four-wheeled engine, modeled after the English pattern of

those days, and it weighed in running order something over five

tons. The cylinders were placed beneath the smokebox and connected

to a pair of cranks on the rear axle, which was placed in front

of the firebox. The driving wheels were 54 inches in diameter,

and the front, wheels 45 inches in diameter. The cylinders were

9½ inches in diameter by 18 inches stroke, and they were

carried beneath the smokebox, as is done today with modern inside-connected

engines. The wheels had cast-iron hubs, wooden spokes and rims,

and wrought-iron tires. The frame was of wood. The boiler was

30 inches in diameter and contained seventy-two copper flues 1½

inches in diameter. The valve motion was given by a single loose

eccentric to each cylinder, and the engine was reversed by changing

the position of the eccentric on the axle by a lever operated

from the firebox. The contract price was $3,000. Mathias W. Baldwin, who founded

the establishment, started in business as a jeweler in a small

shop in Philadelphia in the year 1819. In 1830 the steam railroad

was beginning to make its appearance and establishing itself in

this country, and to gratify public interest the proprietor of

a Philadelphia museum gave an order to Baldwin for the construction

of a miniature locomotive for exhibition. In the spring of 1831

the work was completed and the toy was set in motion on a circular

railroad track at the museum. The success of the model brought

an order to Baldwin for a locomotive from the Philadelphia, Germantown

& Norristown Railroad Company. Guided by his experience with

the little model, and by some memoranda which he had taken of

a locomotive recently imported from England by the Camden &

Amboy Railroad Company, Baldwin completed the curious and historical

locomotive known as "Old Ironsides," of which we give

an illustration on our front page. The engine was tried November

23, 1832, and did duty on the Germantown road and, later, on other

roads for a period of over twenty years. The "Ironsides"

was a four-wheeled engine, modeled after the English pattern of

those days, and it weighed in running order something over five

tons. The cylinders were placed beneath the smokebox and connected

to a pair of cranks on the rear axle, which was placed in front

of the firebox. The driving wheels were 54 inches in diameter,

and the front, wheels 45 inches in diameter. The cylinders were

9½ inches in diameter by 18 inches stroke, and they were

carried beneath the smokebox, as is done today with modern inside-connected

engines. The wheels had cast-iron hubs, wooden spokes and rims,

and wrought-iron tires. The frame was of wood. The boiler was

30 inches in diameter and contained seventy-two copper flues 1½

inches in diameter. The valve motion was given by a single loose

eccentric to each cylinder, and the engine was reversed by changing

the position of the eccentric on the axle by a lever operated

from the firebox. The contract price was $3,000.

The second engine, built in 1834

for the Charleston & Hamburg Railroad Company, was a six-wheeled

engine with a single pair of drivers, 4½ feet in diameter,

carried behind the firebox, with a half-crank axle of Baldwin's

design. The wood and iron wheels used on the "Ironsides"

having proved faulty, the driving-wheels in this case were cast

in solid bell metal. The "Miller" had cylinders 10 inches

in diameter by 16 inches stroke, and weighed in working order

about 8 tons. The boiler was constructed with a high circular

dome over the firebox, a form of construction which was consistently

followed for many years afterward. The next engine, the "Lancaster,"

built in 1834, weighed about 8½ tons, and in that year

five locomotives were completed. In the following year, the business

having outgrown the works, a location was found on Broad and Hamilton

Streets, the site of the present works, then in the suburbs of

the city. From that time on the growth of the plant was rapid,

fourteen engines being built in 1835 and forty in 1836. Without

attempting to go into the details of the progress of the works,

it is sufficient to state that several standard American types

had their origin in the Baldwin shops, and of these, perhaps the

most notable are the "Consolidation," the "Mogul"

and the "Atlantic" types. The Consolidation," from

which the type of this name was named, was built in July, 1866,

for the Lehigh Valley Railway. She was a remarkably powerful engine

for that day, with cylinders 20 by 24; four pairs of drivers connected,

and a Bissell pony truck equalized with the front drivers. The

engine in working order weighed 90,000 pounds. The "Mogul"

class took its rise from an engine built for the Louisville &

Nashville Railroad in 1861. The "Mogul" had three pairs

of drivers connected, and a swinging pony truck, which was later

equalized with the forward drivers. The first "Atlantic"

type of locomotive was built in 1895 for the Atlantic Coast Line,

which was followed by engines of the same type for the Atlantic

City trains of the Philadelphia & Reading Railroad. The 1,000th

locomotive was built in 1861. The 5,000th locomotive, built in

1880, was designed for fast passenger service between Philadelphia

and New York, and to run with a light train at a speed of 60 miles

per hour; its cylinders were 18 by 24, and it was carried on a

four-wheel truck, one pair of 6½-foot driving wheels, and

a pair of 45-inch trailing wheels equalized with the drivers.

The 10,000th locomotive was completed in 1889; the 15,000th in

1896; and the 20,000th in 1902. The second engine, built in 1834

for the Charleston & Hamburg Railroad Company, was a six-wheeled

engine with a single pair of drivers, 4½ feet in diameter,

carried behind the firebox, with a half-crank axle of Baldwin's

design. The wood and iron wheels used on the "Ironsides"

having proved faulty, the driving-wheels in this case were cast

in solid bell metal. The "Miller" had cylinders 10 inches

in diameter by 16 inches stroke, and weighed in working order

about 8 tons. The boiler was constructed with a high circular

dome over the firebox, a form of construction which was consistently

followed for many years afterward. The next engine, the "Lancaster,"

built in 1834, weighed about 8½ tons, and in that year

five locomotives were completed. In the following year, the business

having outgrown the works, a location was found on Broad and Hamilton

Streets, the site of the present works, then in the suburbs of

the city. From that time on the growth of the plant was rapid,

fourteen engines being built in 1835 and forty in 1836. Without

attempting to go into the details of the progress of the works,

it is sufficient to state that several standard American types

had their origin in the Baldwin shops, and of these, perhaps the

most notable are the "Consolidation," the "Mogul"

and the "Atlantic" types. The Consolidation," from

which the type of this name was named, was built in July, 1866,

for the Lehigh Valley Railway. She was a remarkably powerful engine

for that day, with cylinders 20 by 24; four pairs of drivers connected,

and a Bissell pony truck equalized with the front drivers. The

engine in working order weighed 90,000 pounds. The "Mogul"

class took its rise from an engine built for the Louisville &

Nashville Railroad in 1861. The "Mogul" had three pairs

of drivers connected, and a swinging pony truck, which was later

equalized with the forward drivers. The first "Atlantic"

type of locomotive was built in 1895 for the Atlantic Coast Line,

which was followed by engines of the same type for the Atlantic

City trains of the Philadelphia & Reading Railroad. The 1,000th

locomotive was built in 1861. The 5,000th locomotive, built in

1880, was designed for fast passenger service between Philadelphia

and New York, and to run with a light train at a speed of 60 miles

per hour; its cylinders were 18 by 24, and it was carried on a

four-wheel truck, one pair of 6½-foot driving wheels, and

a pair of 45-inch trailing wheels equalized with the drivers.

The 10,000th locomotive was completed in 1889; the 15,000th in

1896; and the 20,000th in 1902.

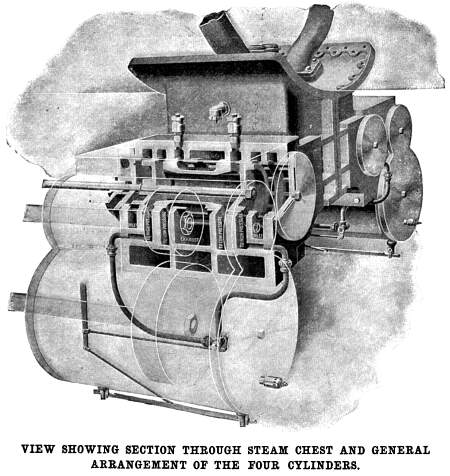

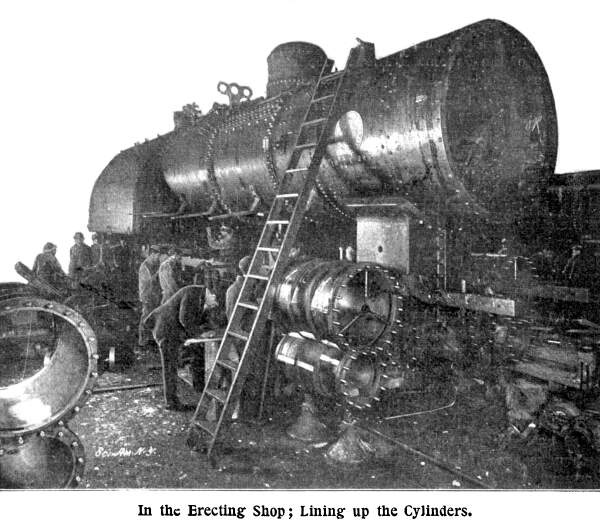

A banner year in the history of

these works was the season of 1889, when the first of the now

celebrated compound locomotives was completed and placed on the

Baltimore & Ohio Railroad. It was of the four-cylinder type

designed by S. M. Vauclain, the general superintendent, a high

and a low-pressure cylinder being carried on either side of the

smokebox, the high-pressure above and the low-pressure below,

although in some later engines the positions are, for convenience,

reversed. The two pistons on either side are connected to a common

crosshead, and each pair of cylinders is cast in one piece with

the piston, steam-chest and one-half of the saddle. The arrangement

is shown very clearly in the accompanying perspective view of

the cylinders. The valve, which is double and hollow, controls

the steam admission and exhaust of both cylinders. The exhaust

steam on the high-pressure cylinder becomes the supply steam for

the low-pressure cylinder; and as the steam for the high-pressure

cylinder enters the steam-chest at both ends the valve is in practically

perfect balance. A by-pass valve is provided to admit live steam

to the low-pressure cylinder in starting. A banner year in the history of

these works was the season of 1889, when the first of the now

celebrated compound locomotives was completed and placed on the

Baltimore & Ohio Railroad. It was of the four-cylinder type

designed by S. M. Vauclain, the general superintendent, a high

and a low-pressure cylinder being carried on either side of the

smokebox, the high-pressure above and the low-pressure below,

although in some later engines the positions are, for convenience,

reversed. The two pistons on either side are connected to a common

crosshead, and each pair of cylinders is cast in one piece with

the piston, steam-chest and one-half of the saddle. The arrangement

is shown very clearly in the accompanying perspective view of

the cylinders. The valve, which is double and hollow, controls

the steam admission and exhaust of both cylinders. The exhaust

steam on the high-pressure cylinder becomes the supply steam for

the low-pressure cylinder; and as the steam for the high-pressure

cylinder enters the steam-chest at both ends the valve is in practically

perfect balance. A by-pass valve is provided to admit live steam

to the low-pressure cylinder in starting.

In view of the fact that there is, even to-day, a rather widespread,

although mistaken, idea among railroad men that the superiority

of the compound to the single-expansion locomotive is doubtful,

it is well to draw attention here to two facts: First, that the

scientific tests which have been made in experimental engineering

laboratories, such as those at Purdue University and Columbia

University, have shown that the compound locomotive is decidedly

more economical than the single-expansion; and,  second,

that where the management, engineers and firemen of a railroad

have taken hold of the compound with the determination to give

it a perfectly fair trial, it has not proved more costly in repairs

and has maintained what we might call its laboratorial reputation

for economy. We quote from a paper on the performance of a four-cylinder

Baldwin, compound locomotive, by Richard A. Smart, Assistant Professor

of Experimental Engineering at Purdue University, in which he

draws the following conclusions: First, that there was with an

increase of speed an increase of horse power and economy up to

270 revolutions per minute; second, the indications were that

the power would increase for speeds considerably above 270 revolutions

per minute; third, the increase in economy with increase of speed

was chiefly due to a decrease of cylinder condensation; fourth,

the average steam consumption of the compound was much lower than

the lowest consumption shown by the single-expansion engine; fifth,

the saving in steam shown by the compound locomotive would result

in a saving in coal of from 18 per cent to 33 per cent. second,

that where the management, engineers and firemen of a railroad

have taken hold of the compound with the determination to give

it a perfectly fair trial, it has not proved more costly in repairs

and has maintained what we might call its laboratorial reputation

for economy. We quote from a paper on the performance of a four-cylinder

Baldwin, compound locomotive, by Richard A. Smart, Assistant Professor

of Experimental Engineering at Purdue University, in which he

draws the following conclusions: First, that there was with an

increase of speed an increase of horse power and economy up to

270 revolutions per minute; second, the indications were that

the power would increase for speeds considerably above 270 revolutions

per minute; third, the increase in economy with increase of speed

was chiefly due to a decrease of cylinder condensation; fourth,

the average steam consumption of the compound was much lower than

the lowest consumption shown by the single-expansion engine; fifth,

the saving in steam shown by the compound locomotive would result

in a saving in coal of from 18 per cent to 33 per cent.

Perhaps the most celebrated locomotives

turned out by these works are those which have been built to haul

the extremely fast trains which are running between Camden, across

the Delaware River from Philadelphia, and Atlantic City. These

are of the celebrated "Atlantic" type in which the cylinders

drive the rear pair of four-coupled drivers and the weight of

the firebox is carried by a pair of trailers. Engine 1027 was

built under guarantee to haul a train of eight cars (four coaches

and four Pullmans) to Atlantic City, a distance of 55.5 miles,

in sixty minutes; or to haul six cars over the same distance in

fifty minutes, with a development of an estimated horse power

of 1,400. In practice, however, this locomotive exceeded the guarantee

by about 10 per cent. Another of the "Atlantic" type

was built for the Chicago, Milwaukee & St. Paul Railroad,

under contract to haul nine cars between Milwaukee and Chicago

in one hour and forty-five minutes, with an estimated development

of maximum horse power of 1,600. One of the latter engines exceeded

the guarantee by four cars, hauling thirteen cars, in the specified

time, the train and locomotive together weighing 600 tons. Following

on these excellent results the company proceeded to make accurate

tests of 1027 to determine just what the locomotive was capable

of. It was found that with an experimental train of twelve coaches

the horse power increased directly with the speed until it reached

1,450 horse power at 70 miles an hour, and even at this speed

the locomotive had a reserve of power to overcome grade resistance

or to enable it to accelerate the train to a higher speed. Perhaps the most celebrated locomotives

turned out by these works are those which have been built to haul

the extremely fast trains which are running between Camden, across

the Delaware River from Philadelphia, and Atlantic City. These

are of the celebrated "Atlantic" type in which the cylinders

drive the rear pair of four-coupled drivers and the weight of

the firebox is carried by a pair of trailers. Engine 1027 was

built under guarantee to haul a train of eight cars (four coaches

and four Pullmans) to Atlantic City, a distance of 55.5 miles,

in sixty minutes; or to haul six cars over the same distance in

fifty minutes, with a development of an estimated horse power

of 1,400. In practice, however, this locomotive exceeded the guarantee

by about 10 per cent. Another of the "Atlantic" type

was built for the Chicago, Milwaukee & St. Paul Railroad,

under contract to haul nine cars between Milwaukee and Chicago

in one hour and forty-five minutes, with an estimated development

of maximum horse power of 1,600. One of the latter engines exceeded

the guarantee by four cars, hauling thirteen cars, in the specified

time, the train and locomotive together weighing 600 tons. Following

on these excellent results the company proceeded to make accurate

tests of 1027 to determine just what the locomotive was capable

of. It was found that with an experimental train of twelve coaches

the horse power increased directly with the speed until it reached

1,450 horse power at 70 miles an hour, and even at this speed

the locomotive had a reserve of power to overcome grade resistance

or to enable it to accelerate the train to a higher speed.

It is a well-known fact that at the higher speeds the single-expansion

locomotive is subject to drawbacks in the shape of wire drawing

of the steam, back pressure in the cylinders and overforcing of

the fire, which are absent in the compound with its wider range

of expansion and its milder exhaust. Careful tests have shown

over and over again that there is about 25 per cent economy in

a compound as compared with a single-expansion locomotive doing

the same work. This is due to the less evaporation required to

develop the necessary energy, together with the slower rate of

combustion of fuel resulting from exhausting the steam at lower

tension. Of course, it is understood that these results are only

obtained, as we have before remarked, where the management and

operatives of the road are in thorough sympathy with the compound,

and are desirous of giving it every facility to show its best

results.

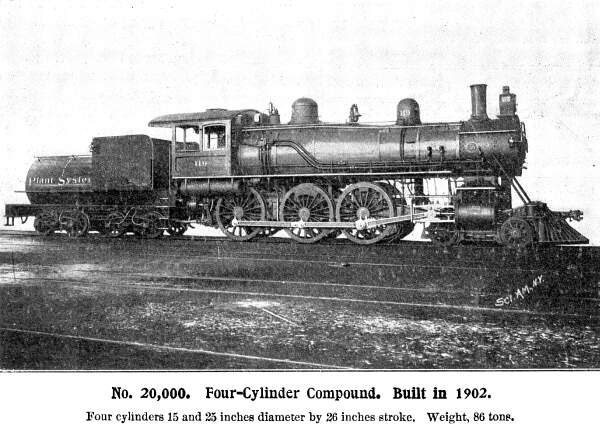

The 20,000th locomotive, of which

we present an illustration, is a further improvement in which

it is sought to secure a more perfect balance of the reciprocating

parts than is possible on the ordinary type. The high and low-pressure

cylinders, instead of being arranged above one another in a vertical

plane, are all carried in one horizontal plane, the high-pressure

cylinders within the frames beneath the smokebox and the low-pressure

cylinders on the outside of the frames. The low-pressure crossheads

are connected with the main driving wheels by outside connecting

rods as in ordinary practice. The main driving axle has two cranks,

which are set at right angles to each other on each side of the

center of the locomotive, and each crank is coupled to the crosshead

of one of the high-pressure pistons. The crank on the axle and

the crank-pin in the wheel for the corresponding high and low-pressure

cylinders are set at an angle of 180 degrees, and the two axle

cranks being set at 90 degrees results in the action of each high

and low-pressure cylinder, on one side of the locomotive quartering

with the equivalent cylinders on the opposite side. As a consequence,

an almost perfectly balanced engine is secured, and the amount

of counter-balance required is reduced to a very low limit. The

arrangement is the same as was used by Strong in his locomotive

that attracted so much attention a dozen or more years ago, and

it has lately been adopted with very good results on two or three

of the English roads. Other special features of No. 20,000 are

that it carries the Vanderbilt boiler and tender. In the former

the firebox is cylindrical and corrugated, and in the tender the

water tank is cylindrical, and the coal box is built at the front

end of the tender and is, therefore, very conveniently placed

for the fireman. The locomotive weighs in working order 176,510

pounds, of which 127,010 pounds are on the driving wheels. The

weight of the tender loaded is 99,000 pounds. The driving wheels

are 73 inches in diameter and the cylinders are 15 and 25 in diameter

by 26 inches stroke. The boiler has a total heating surface of

2,793 square feet, of which 128 square feet are in the firebox. The 20,000th locomotive, of which

we present an illustration, is a further improvement in which

it is sought to secure a more perfect balance of the reciprocating

parts than is possible on the ordinary type. The high and low-pressure

cylinders, instead of being arranged above one another in a vertical

plane, are all carried in one horizontal plane, the high-pressure

cylinders within the frames beneath the smokebox and the low-pressure

cylinders on the outside of the frames. The low-pressure crossheads

are connected with the main driving wheels by outside connecting

rods as in ordinary practice. The main driving axle has two cranks,

which are set at right angles to each other on each side of the

center of the locomotive, and each crank is coupled to the crosshead

of one of the high-pressure pistons. The crank on the axle and

the crank-pin in the wheel for the corresponding high and low-pressure

cylinders are set at an angle of 180 degrees, and the two axle

cranks being set at 90 degrees results in the action of each high

and low-pressure cylinder, on one side of the locomotive quartering

with the equivalent cylinders on the opposite side. As a consequence,

an almost perfectly balanced engine is secured, and the amount

of counter-balance required is reduced to a very low limit. The

arrangement is the same as was used by Strong in his locomotive

that attracted so much attention a dozen or more years ago, and

it has lately been adopted with very good results on two or three

of the English roads. Other special features of No. 20,000 are

that it carries the Vanderbilt boiler and tender. In the former

the firebox is cylindrical and corrugated, and in the tender the

water tank is cylindrical, and the coal box is built at the front

end of the tender and is, therefore, very conveniently placed

for the fireman. The locomotive weighs in working order 176,510

pounds, of which 127,010 pounds are on the driving wheels. The

weight of the tender loaded is 99,000 pounds. The driving wheels

are 73 inches in diameter and the cylinders are 15 and 25 in diameter

by 26 inches stroke. The boiler has a total heating surface of

2,793 square feet, of which 128 square feet are in the firebox.

Build a Locomotive

| Contents Page

|