THE VALUE OF COMPRESSED

AIR IN AND ABOUT RAILROAD SHOPS.

Railway Engineering and Mechanics—November,

1894

BY F. M. TWOMBLY,

Master Mechanic New York, New Haven & Hartford R.R.

The writer, having the supervision of a railway shop that cares

for eighty locomotives making about 210,000 miles per month, also

building all the tanks for 260 locomotives, became Interested

in the use of compressed air and commenced using it In the summer

of 1891, and probably at the present time is using it as extensively

as most any one with a shop of equal size; and he is now prompted

by the numerous inquiries constantly received, to give to the

readers of RAILWAY ENGINEERING

AND MECHANICS, in

a general way, what it is like and what it is worth, as he found

it, without going too much into details.

In applying the numerous devices for the utilization of compressed

air in a shop, much depends upon the way the shop is constructed,

its height, location of machinery, etc.; but more depends upon

the ingenuity of the person making the application, as two shops

cannot be fitted alike, unless they are built and equipped alike.

Those mechanics who are skeptical regarding the utility and economy

of compressed air, the writer would be glad to show his plant;

to those who cannot see it, it will be made as plain as possible

by means of the accompanying illustrations.

With us pneumatic lifts have entirely superseded in the shops

and yard, chain falls, rope falls and blocks, and cranes. So much

has been written about pneumatic lifts that a minute description

of them at this time, is probably not necessary. I will observe,

however, that by the aid of 'seamless tubes, cold rolled steel

for piston rods, leather packing, and cast iron heads bolted together

with rods, their construction is a very simple matter, and inexpensive

in comparison with any other kind of lift. For cylinders 7¾

inches in diameter and less, we use brass; for larger sizes, wrought

iron. To smooth the inside of the latter tubes, a cast iron "slug"

turned a trifle larger than the tube and kept well greased, is

forced through them with hydraulic press. For this idea the writer

is indebted to Mt. J. H. Manning, master mechanic U.P.R.R., Omaha

Neb.

Where the height of a building is insufficient, hoists can

be just as well used horizontally, pulling over a sheave, the

loss by friction, of course, being a little more. In some experiments

made by us, the loss by friction on the direct lift was found

to, be about 3 per cent.

The matter of compressors will not be touched upon in this

article as no opportunity has existed for comparisons, the ordinary

locomotive air pump having been used exclusively; nor have we

made experiments to determine the amount of coal consumed, but

are confident that the amount is a mere ''bagatelle" when

compared with the results obtained and saving made.

The first lift

constructed was 6 inches in diameter and took the place of a chain

fall used in lifting steel rails into place for dri1ling holes,

which was being done by two men receiving $1.75 and $1.50 respectively,

the change paying more than 300 per cent on the investment. The first lift

constructed was 6 inches in diameter and took the place of a chain

fall used in lifting steel rails into place for dri1ling holes,

which was being done by two men receiving $1.75 and $1.50 respectively,

the change paying more than 300 per cent on the investment.

Air is being used for lifting ashes, made by locomotives, from

the pits to the cars, the apparatus costing less than $200. The

saving over the old method is over $600 per annum, or more than

300 per cent. This is in, constant use every day of the year.

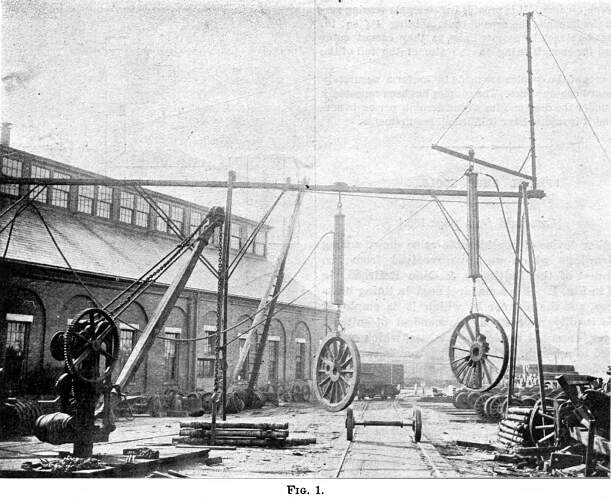

A glance at Fig. 1 will show an overhead railway, constructed

of old rails, a crane, and shears, all operated by air; also an

old crane now obsolete. With the old crane, which is a good one,

five men will use 64 minutes in loading on a car, 16 pair of tender

or car wheels, while with the new crane the same men will do the

work in 10 minutes. While at present there is attached to the

shears only a medium sized cylinder, it is obvious that the size

of the cylinder need only be limited to the strength of the shears.

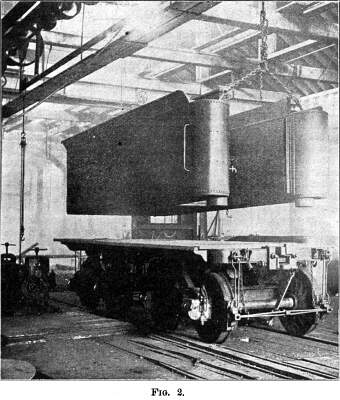

Fig. 2 shows a completed tank, weighing 7,540 lbs., in tank

shop, being raised to place on tender frame. This is accomplished

by two cylinders which lie horizontally on chords of roof, either

of them being capable of raising the load separately. These are

also used for turning tanks over, or, in fact, anything that requires

any pulling.

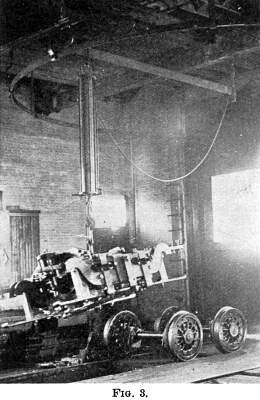

The reader's

attention is particularly called to the overhead arrangement to

which hoist is suspended in Fig. 3. It is a horizontal bar, one

end of which is hung on a spindle or pivot, the other end having

a trolley running on a bar which is an arc of a circle, the pivot

being the center. With the hoist movable on the bar that forms

the radius, it is plain that all of the territory within the sector

can be covered. There are in use in our machine shop about a dozen

of these, ranging from an are of sixty degrees to a full circle. The reader's

attention is particularly called to the overhead arrangement to

which hoist is suspended in Fig. 3. It is a horizontal bar, one

end of which is hung on a spindle or pivot, the other end having

a trolley running on a bar which is an arc of a circle, the pivot

being the center. With the hoist movable on the bar that forms

the radius, it is plain that all of the territory within the sector

can be covered. There are in use in our machine shop about a dozen

of these, ranging from an are of sixty degrees to a full circle.

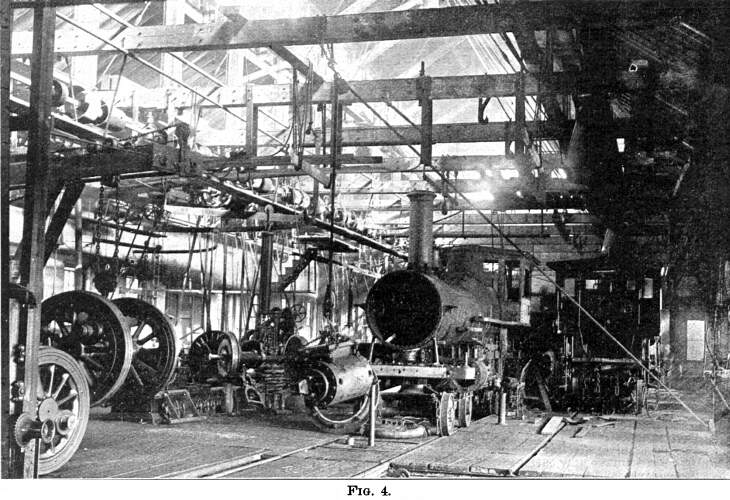

Fig. 4 illustrates how a stationary hoist may be, used to raise

weights at a considerable distance away by means of snatch blocks.

If the bight of the rope, that is seen lifting the cylinder, was

made fast to the "dead man" in floor, and another snatch

block placed in the bight and hooked to the piston, the hoist

would lift half of its capacity through twice its space; we make

considerable use of air in this way. The large driving wheel crane

seen in left of picture, although operated by air, is to be superseded

by overhead railway seen under construction. Immediately back

of cylinder suspended by rope, is a ram coming up through the

floor which is a driving wheel jack, of which we have several,

they being made of old locomotive cylinders. For smaller wheels

we use jacks made of seven inch tender cylinders.

Our bolt cutter is supplied with oil from a reservoir underneath;

constant air pressure is maintained on top of oil, and the flow

is regulated by a cock. Oil after being used is strained into

a pan under the machine and above the reservoir, and when desirable

is conducted back to the reservoir by gravitation, the air being

shut off and a bleeder on the reservoir opened. This arrangement

is better, costs less and is preferable to a pump. The same principle

is used by us in transferring oil from barrels to tanks.

This principle will also be applied to a machine, which we

have under construction, for forcing sand from a reservoir, the

top of which will, be on floor level, to a tank in top of engine

house, from which the sand will be conveyed to sand: boxes of

locomotives the same as water is to tenders. While this machine

is not in operation, experiments have satisfied us that it will

be a success.

We have a pressure gage in the office for registering at all

times, the pressure on, the air plant, and having piped to the

office for this purpose we also operate our letter-copying press

with air.

We have about 300 cubic feet of air storage, about half of

which is in the old boiler. There are many uses that we make of

compressed air not enumerated in this article. Some of them were

mentioned in a former article appearing in RAILWAY

ENGINEER ING AND

MECHANICS for March, 1893.

The writer is decidedly of the opinion that the value of compressed

air in shops cannot well be overestimated.

Build a Locomotive

| Contents Page

|