|

CHAPTER XI.

INJECTORS.

ALTHOUGH the injector is not theoretically so efficient as

a good pump, practically it has proved itself the best means of

feeding water to locomotive boilers that has ever been tried.

When a well-made injector is used regularly, it is more reliable

than any form of pump, is more easily examined and repaired when

it gets out of order, is less liable to freeze or to sustain damage

from accidental causes, and it regulates the quantity of water

required as well as the ordinary pump, and better than any pump

actuated by the machinery of the engine, when the speed of a train

is irregular. The injector also possesses the important advantage

that it raises the temperature of the feed-water to approach the

temperature of the boiler, thereby avoiding shocks and strains

to metal that very cold water is likely to impart.

So long as injectors were imperfectly understood, and were

used with no regularity, they retained the name of being unreliable;

but so soon as they began to be made the sole feeding medium for

locomotive boilers, they had to be worked regularly, and kept

in order, which quickly made their merits recognized.

INVENTION OF THE INJECTOR.

The feed injector was invented by Henri Giffard, an

eminent French scientist and aeronaut. Its successful action was

discovered during a series of experiments, made with the view

of devising light machinery that might be used to propel balloons.

Although Giffard designed the most perfect balloon that was ever

constructed, the injector was not used upon it. and the invention

was laid aside and almost forgotten. During the course of a sea-voyage,

Giffard happened to meet Stewart of the engineering firm, Sharp,

Stewart & Co., of Manchester, England. In the course of a

conversation on the feeding of boilers, Giffard remembered his

injector, and mentioned its method of action. Stewart was struck

with the simplicity of the device, and undertook to bring it out

in England, which he shortly afterwards did, representing the

interests of the inventor so long as the original patents lasted.

By his advice, William Sellers & Co., of Philadelphia, were

given control of the American patents. Seldom has an invention

caused so much astonishment and wild speculation among mechanics,

and even among scientists, as the injector did for the first few

years of its use. Scientists were not long in discovering the

philosophy of the injector's action, but that knowledge spread

more slowly among mechanics. It was regarded as a case of perpetual

motion — the means of doing work without power, or, as Americans

expressed it, by the same means a man could raise himself by pulling

on his bootstraps.

PRINCIPLE OF THE INJECTOR'S ACTION.

Although the mechanism of the injector is very simple, the philosophy

of its action is not so easily understood as the principles on

which a pump raises water and forces it into the boiler. On beginning

to investigate the action of the injector, it appears a physical

paradox, the finding that steam at a given pressure leaves a boiler,

passes through several tortuous and contracted passages, raises

several check-valves, and then forces water into the boiler against

a pressure equal to that which the steam had when it first began

the operation. At first acquaintance the operation looks as if

it had a strong likeness to perpetual motion, but closer investigation

will show that the steam which raises and forces the water by

passing through an injector performs mechanical work as truly

as the steam that pushes a piston which moves a pump-plunger.

A current of any kind, be it steam, air, water, or other matter,

has a tendency to induce a movement in the same direction of any

body with which it comes in contact. Thus, we are all familiar

with the fact that a current of air called wind, passing over

the surface of a body of water, sets waves in motion, and dashes

the water high up on the shore away above its original level.

In the same way a jet of steam moving very rapidly, when injected

into a body of water, under favorable conditions, imparts a portion

of its motion to the water, and starts it with momentum sufficient

to overcome a pressure even higher than the original pressure

of the steam. The locomotive blast, blowers, steam siphons, steam

jets, jet exhausters, vacuum ejectors, and argand burners, are

all common instances of the application of the principle of induced

currents.

VELOCITY OF STEAM AND OF WATER.

At a boiler pressure of 140 pounds per square inch steam passes

into the atmosphere with a velocity of 1920 feet per second. When

steam at this speed strikes like a lightning-flash into the tubes

of the injector, it becomes the ram which forces the water towards

the boiler; but its power is opposed by the tendency of the water

inside the boiler to escape through the check-valve. The velocity

with which water will flow from a vessel is known to be equal

in feet to the square root of the pressure multiplied by 12.19.

Accordingly, in the case under consideration, the water inside

of the boiler would tend to escape at a speed of 144 feet per

second. This represents the resistance at the check-valve. The

mechanical problem, then, to be worked out by the injector is

to transform the energy of hot steam moving at a high velocity

into the momentum possessed by a heavier and colder mass of water.

In the operation the steam yields up a portion of its heat and

the greater part of its velocity, but it keeps a current of water

flowing fast enough to overcome the static resistance at the check-valve.

TEMPERATURE OF INJECTED WATER.

A common delivery temperature of the water forced through an injector

is 160 degrees Fahr. Taking the feed-water at 55 degrees Fahr.,

we find that the steam used in operating the injector imparts

105 degrees Fahr. to the feed-water before putting it into the

boiler. One pound of steam at 140 pounds boiler-pressure contains

1224 heat units reckoned above zero. When the hot steam speeding

at a high velocity strikes the feed-water, part of the heat is

converted into the mechanical work required to put the water in

motion, but there still is left heat sufficient to raise about

11 pounds of water to the temperature of 160 degrees. One pound

of steam, therefore, communicates to 11 pounds of water the motion

required for overcoming the resistance encountered at the. check-valve.

The steam moving at a speed of 1920 feet per second having imparted

motion to a body eleven times its own weight, itself in the mean

time having become a portion of the mass, the velocity of the

feed-water would be 1920 / 12 = 170 feet per second. When the

reduction of speed due to friction of the pipes and other resistances

is considered, there still remains momentum enough in the water

to raise the check-valve.

Although 160 degrees is about the average heat of the water

delivered by lifting injectors, instruments can be designed so

that they will heat the water much higher. With non-lifting injectors,

the feed-water is nearly always delivered at a higher temperature

than with the other kind.

ELEMENTARY FORM OF INJECTOR.

There are numerous forms of injectors in use, but they are all

developments of the elementary arrangement of parts shown in the

annexed illustration, Fig. 1. Steam at a high velocity passes

from the boiler into the tube A, and striking the feed-water

at B, is itself condensed, but imparts momentum to the

water to send it rushing along into the delivery pipe E

with sufficient force to raise the check-valve against the pressure

inside and pass into the boiler. As the current of water could

not be started into rapid motion against the constant pressure

of the check-valve, an overflow opening is provided in the injector,

through which the water can flow unchecked till the necessary

momentum is obtained, when the overflow valve is closed.

In a lifting injector, the parts are so designed that, in starting,

a jet of steam passes through the combining tube at sufficient

velocity to create a vacuum in the water-chamber XX, and

the water is drawn into this place from the feed-pipe as if by

the suction of a pump. The steam-jet then striking the water starts

it into motion. If too much steam is admitted for the quantity

of water passing, air will be drawn in through the overflow opening,

mixing with the water and reducing its compactness, while some

uncondensed steam will pass through with the water. This will

reduce the force of impact of the feed-water upon the boiler check,

and when it becomes so light that the momentum of feed-water is

no greater than the resistance inside the boiler, the injector

will break. On the other hand, when the quantity of water supplied

is too great for the steam to put into high motion, part will

escape through the overflow valve. In some forms of injectors,

separate appliances are used for raising the water from the forcing

chamber to the source of supply.

As the successful operating of the injector is dependent on

the feed-water promptly condensing the steam which supplies the

power, water of a very high temperature cannot be fed by an injector.

A certain amount of live steam must be condensed by the feed-water

to impart the momentum necessary to make the latter overcome the

resistance at the check-valve. When the feed-water becomes hotter

than 100 degrees Fahr. a point is soon reached where it takes

such a large body of water to condense the steam that there is

not the required velocity generated to force the feed water into

the boiler.

All deviations from the elementary form of injector shown are

made for the purpose of extending the action of the instrument

under varied conditions, for making it work automatically under

different pressures of steam, and for increasing its capacity

for raising the water to be used above its natural level.

CARE OF INJECTORS.

When an engineer finds that an injector refuses to work, his first

resort should be the strainer. That gets choked with cinders or

other impurities so frequently that no time should be lost in

examining it. One day when I was running a round-house, an engineer

came in breathless, with the information that his engine was blocked

in the yard, and he must dump his fire, as he could not get his

injector to work. The thermometer stood at twenty degrees below

zero, and an Iowa blizzard was blowing; so the prospect of a dead

engine in the yard meant some distressingly cold labor. I asked,

the first thing, if he had tried the strainer; and his answer

was that the strainer was all right, for the injector primed satisfactorily,

but broke every time he put on a head of steam. I went out to

the engine, and had the engineer try to work the injector. By

watching the overflow stream, I easily perceived that the injector

was not getting enough water, although it primed. An examination

showed that the strainer was full of cinders, and the injector

went to work all right as soon as the obstruction to the water

was removed.

THE MOST COMMON CAUSES OF DERANGEMENT.

Sand and cinders are the most common causes of failure with injectors,

as they are indeed with all water feeding apparatus. A very common

cause of failure of injectors is leakage of steam through throttle-valve

or check-valve, keeping the tubes so hot that no vacuum can be

formed to make it prime. A great many injector-checks have been

turned out too light for ordinary service, while others are made

in a shape that will always leave the valve away from the seat

when they stop working. Then the engineer has to run forward,

and pound the check with a hammer to keep the steam from blowing

back, and that soon ruins the casting. Check-valves set in a horizontal

position are worthless with water that contains grit.

HOW TO KEEP AN INJECTOR IN GOOD ORDER.

To preserve a good working injector, the engineer should see that

the pipes and joints are always perfectly tight. Of course it

is difficult to keep them tight when they are subjected to the

continual jars a locomotive must stand; but injectors cannot be

depended on where there is a possibility of air mixing with the

water. Leaky joints or pipes are particularly troublesome to lifting

injectors; for air passes in, and keeps the steam-jet from forming

a vacuum. At first the injector will merely be difficult to start;

but as the leaks get worse there will be no starting it at all.

Then, the air mixing with the water is detrimental to the working

of all injectors, as its tendency is to decrease the speed of

the water. The compact molecules of water form a cohesive body,

which the steam can strike upon with telling force to keep it

in motion. When the water is mixed with air it lacks the element

of compactness, and the steam-jet strikes a semi-elastic body

which does not receive momentum readily. This mixture of steam

and air does not act solidly on the check-valve, but makes the

water pass in with a bubbling sound, as if the valve were moving

up and down; and the stream of water breaks very readily when

it is working in this way.

COMMON DEFECTS.

As maintaining unbroken speed on the water put in motion is the

first essential in keeping an injector in good working order,

anything that has a tendency to reduce that speed will jeopardize

its action. A variety of influences combine to reduce the original

efficiency of an injector. Those with fixed nozzles are constructed

with the orifices of a certain size, and in the proportion to

each other which experiment has demonstrated to be best for feeding

with the varied steam-pressures. When these orifices become enlarged

by wear the injector will work badly, and nothing will remedy

the defect but new tubes. The tubes sometimes get loose inside

the shell of the injector, and drop down out of line. The water

will then strike against the side of the next tube, or on some

point out of the true line, scattering it into spray which contains

no energy to force itself into the boiler. A machinist examining

a defective injector should always make sure that the tubes are

not loose. Injectors suffering from incrusted water-passages will

generally work best with the steam low. In districts where the

feed-water is heavily charged with lime salts, it is common for

injectors to get so incrusted that the passages are almost closed.

Joints about injectors that are kept tight by packing must

be closely watched. Many an injector that failed to work satisfactorily

has been entirely cured by packing the ram-gland.

CARE OF INJECTORS IN WINTER.

During severe frosty weather an injector can be kept in order

much easier than a pump; but it needs constant watching and intelligent

supervision.

To keep an injector clear of danger from frost, it should be

fitted with frost-cocks so that all the pipes can be thoroughly

drained. Bends in the pipes, where water could stand, should be

avoided as far as possible; and where they cannot be avoided,

the lowest point should contain a drain-cock.

To operate an injector successfully, thoughtful care is requisite

on the part of the engineer; and where this is given, the injector

will prove itself a very economical boiler-feeder.

The injectors principally used in American locomotives are

the Sellers, the Nathan, the Mack, and the Rue Little Giant. All

are good reliable boiler-feeders, and all are made to wear well

under the rough service met with on locomotives.

THE SELLERS INJECTOR.

When the Giffard injector was first introduced into this country

by William Sellers & Co., Philadelphia, it was a rather defective

boiler-feeder; but that firm effected great improvements and led

the way for making the injector the popular boiler-feeder it is

to-day. They made the instrument self-adjusting, and improved

its design so that it would feed automatically, however much the

pressure of the boiler varied, and, finally they perfected it

so that, should anything happen to interrupt its working, it would

automatically restart itself. The latest development of the injector

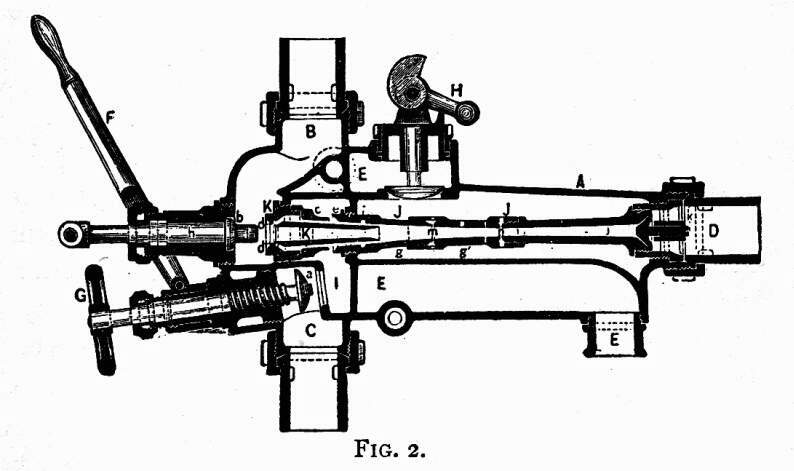

is shown by a sectional view in Fig. 2.

This instrument will start at the lowest steam pressures with

water flowing to it, and will lift the water promptly even when

the suction-pipe is hot. At 10 pounds steam pressure it will lift

the Water 2 feet; at 30 pounds, 5 feet; and at all ordinary pressures,

say 60 pounds and over, it will lift from 12 to 18 feet. It can

be used as a heater for the water supply by simply closing the

waste-valve and pulling out the steam-lever.

By reference to the cut it will be seen that this injector

consists of a case A provided with a steam inlet B,

a water-inlet C, an outlet D through which the water

is conveyed to the boiler, an overflow opening E, a lever

F by which to admit steam, stop and start its working,

a hand-wheel G to regulate the supply of water, and an

eccentric lever H to close the waste-valve when it is desired

to make a heater of the injector.

Its operation is as follows:

The water-inlet C being in communication with water

supply, the valve a is open to allow the water to enter

the chamber I, Steam is admitted to the chamber B,

and the lever F is drawn out to lift the valve b

from its seat and permit the steam to enter the annular lifting

steam-nozzle c through the holes d d. The steam issuing

from this nozzle passes through the annular combining tube e

and escapes from the instrument partly through the overflow opening

f and partly through the overflow openings provided in

the combining tube g g, through the overflow chamber J

and passage E E, and produces a strong vacuum in the water

chamber I which lifts the water from the source of supply,

and the united jet of steam and water is, by reason of its velocity,

discharged into the rear of the receiving end of the combining

tube g. The further movement of the lever F withdraws

the spindle h until the steam-plug i is out of the

forcing nozzle K, allowing the steam to pass through the

forcing nozzle K and come in contact with the annular jet

of water which is flowing into the combining tube around the nozzle

K. This jet of water has already a considerable velocity,

and the forcing steam jet imparts to it the necessary increment

of velocity to enable it to enter the boiler through the delivery

tube j and boiler check k.

If from any cause the jet should be broken—say from a

failure in the water supply—the steam issuing from the forcing

nozzle K into the combining tube g will escape through

the overflows m and n and intermediate openings

with such freedom that the steam, which will return through the

annular space formed between the nozzle K and combining

tube g, and escape into the overflow chamber through the

opening f, will not have sufficient volume or force to

interfere with the free discharge of the steam, issuing from the

annular lifting steam-nozzle and escaping through the same overflow

F, and hence the lifting steam-jet will always tend to

produce a vacuum in the water-chamber I, which will again

lift the water when the supply is renewed, and the combined annular

jet of steam and water will be forced into the combining tube

g against the feeble current of steam returning, when the

jet will again be formed and will enter the boiler as before.

In actual practice on a locomotive the movement of the lever F

in starting the injector is continuous.

NATHAN MFG. CO.'S IMPROVED MONITOR INJECTOR.

One of the most successful and enduring injectors in use is the

Monitor, the distinguishing feature of which originally was that

the injector is constructed with fixed nozzles, that insure great

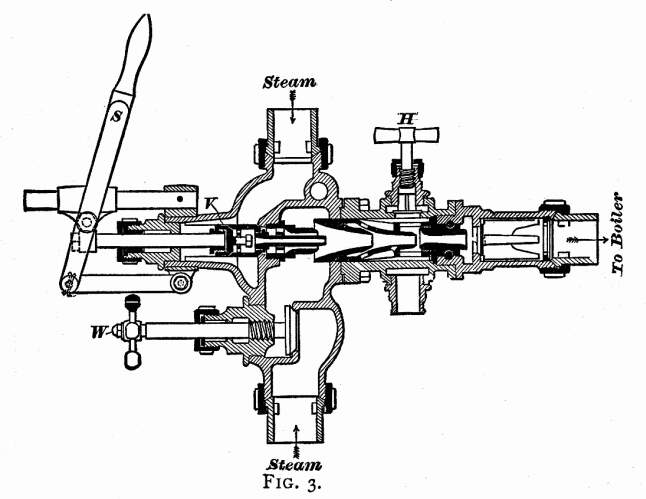

durability, combined with certainty of action. The injector shown

in Fig. 3 is an improvement on the old Monitor, the radical change

being that this injector is operated by a single lever. Any one

who has studied the operation of the injector already described

will have no difficulty in perceiving how the new Monitor works.

It will be seen that steam is admitted from the top to the tube

that forms the body of the injector, and the water from below.

To start the injector, the water-valve W is opened. The

main lever S is then pulled out a short distance to lift

the water; when the water begins to escape through the overflow

the lever S is steadily drawn back, which puts the injector

working at its maximum power. The quantity of feed required is

graduated by the valve W.

When it is desired to use the injector as a heater, close the

valve H and. pull out the lever S all the way. At

other times the valve H must be kept open.

With a boiler pressure of 30 pounds this injector will lift

the water 5 feet, and at ordinary working pressure the steam will

have power to lift the water to a height not likely to arise in

locomotive practice.

THE MACK INJECTOR.

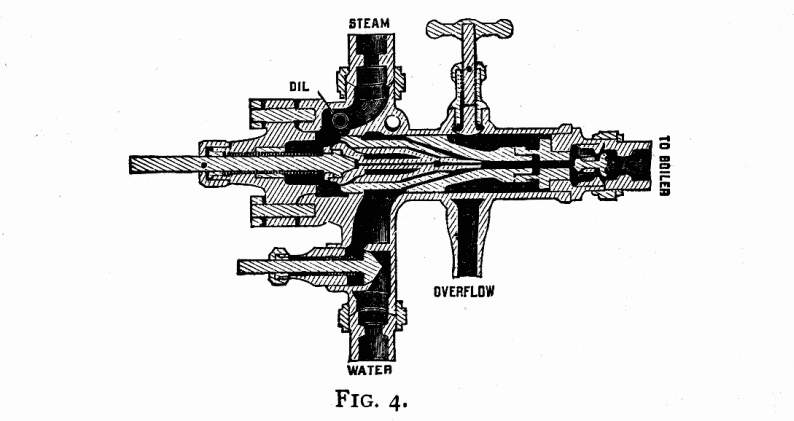

The engraving gives a sectional view of the well known Mack injector,

which is one of the oldest and has long been a favorite on many

roads. The parts are strikingly simple, and they are designed

in very compact form. The section shows the arrangement very clearly.

The cone and tubes can be easily re-moved for cleaning; or should

they get cut by the sand in gritty water, or filled with incrustation,

they can betaken out and replaced by a new set in a few minutes,

the interchangeable parts being kept in stock. There is but one

water-passage and it is very large, so that there is very little

danger of sand or mineral deposits interfering with the efficiency

of the injector.

To work this injector, the steam-valve is opened one quarter

of a turn to lift the water; when water begins to escape from

the overflow, the steam-valve is opened till the water ceases

to pass out of the overflow opening. The supply is regulated by

the lazy-cock.

A special claim made for this injector is the wide range of

its delivery. The supply can be regulated to the absolute requirements

of the boiler, be the train fast or slow, light or heavy. It will

start readily at 30 pounds pressure and work up to any pressure

required. Below 50 pounds pressure it may be necessary to partly

close the supply of water.

LITTLE GIANT INJECTOR.

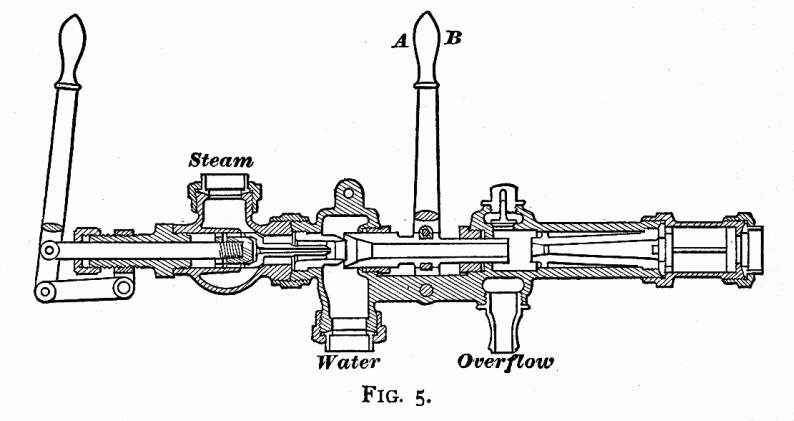

This injector, made by the Rue Manufacturing Co. is a highly efficient

boiler-feeder, and a very simple apparatus. The construction is

clearly seen in the engraving. A unique feature about this injector

is the movable combining tube adjusted by a lever, causing the

feed to be exactly suited to the service. Moving the lever towards

A tends to cut off the feed, and moving towards B

increases it.

To work the injector, the combining tube lever is set in position

to admit sufficient water to condense the steam from the starting

valve. The starting valve is then opened slightly till the water

begins to escape from the overflow, when it is opened full. The

feed is then regulated by the combining tube lever. To use this

injector as a heater, the overflow is closed by the combining

tube being moved up against the discharge, and opening the starting

valve sufficiently to admit the quantity of steam required.

Table of Contents

| Contents Page

|