|

CHAPTER XVIII.

THE SHIFTING LINK

EARLY REVERSING MOTIONS.

IN the engineering practice of the world, before the

locomotive and marine engines came into use, there was no need

for devices to make engines rotate in more than one direction.

When the need for a reversible engine first arose, it was met

by very crude appliances. Locomotives were kept at work, earning

money for their owners, which were reversed by the man in charge

stopping the engine, and by means of a wrench changing the position

of the eccentric by hand. A decided improvement on the wrench

was the movable eccentric, which was held in forward or back gear

by stops; the operation of reversing being done by a treadle or

other attachment located near the engineer's position. A serious

objection to this form of reversing gear was, that the abrasion

of work enlarged the slot ends, and wore out the stops, leading

to inaccuracy and frequent breakage. A somewhat better form of

reversing motion was a fixed eccentric, with the means at the

end of the eccentric-rod for engaging with the top or bottom of

a rocker-shaft, which operated the valve-stem. This was the form

of reversing motion used on the early Baldwin engines. Numerous

other appliances, more or less defective, were experimented with

before the double fixed eccentrics were introduced. Till the link

was applied to valve-motion, the double eccentrics—an American

invention—were the most important improvement that had been

made on the locomotive valve-motion since the incipiency of the

engine. The 'V' hook, in connection

with the double eccentrics, made a fair reversing motion in comparison

to any thing that had preceded it. The objection to the hook was,

that, when the necessity arose for reversing the engine while

in motion, much difficulty was experienced in getting the hook

to catch the pin. As a simple, prompt, and certain reversing motion,

the link was readily acknowledged to be far superior to any thing

that had previously been tried.

INVENTION OF THE LINK.

There is no doubt but the link was first applied to

a steam engine by William T. James of New York, a most ingenious

mechanic, who also invented the double eccentrics. James experimented

a great deal about the period from 1830 to 1840, with steam carriages

for common roads; and it was in this connection that he invented

the link. His work having proved a commercial failure, the improvements

on the valve-motion were not recognized at the time; although

the probability is, that Long, who started the Norris Locomotive

Works of Philadelphia, and brought out the double eccentrics upon

the locomotives built there, was indebted to James for the idea

of a separate eccentric for each direction of engine movement.

The credit of inventing the ordinary shifting link is due to

William Howe of Newcastle, England. This inventor was a pattern-maker

in the works of Robert Stephenson & Co., and he invented the

link in 1842 in practically its present form. The idea of Howe

was to get out an improved reversing motion; and he made a pencil-sketch

of the link, to explain his views to his employers. The superintendent

of the works was favorably disposed to the invention, and ordered

Howe to make a pattern of the motion, which was done; and this

was submitted to Stephenson, who approved of the link, and directed

that one should be tried on a locomotive. Although Stephenson

gave Howe the means of applying his invention, he does not seem

to have perceived its actual value, for the link was not patented;

and Stephenson never failed to patent any device which he thought

worth protecting.

The link-motion was applied to a locomotive constructed for

the Midland Railway Company, and proved a success from the day

it was put on. Seeing how satisfactorily the invention worked,

Robert Stephenson paid Howe twenty guineas (one hundred and five

dollars) for the device, and adopted the link as the valve-gear

for his locomotives. This is how the shifting link comes to be

called the "Stephenson link," and the credit for this

invention was not extravagantly paid for.

The capability which the link possesses of varying the steam

admission and release, did not appear to be understood by the

inventor; nor was the mechanical world aware, for some time after

the link was brought into use, that it could be employed to adjust

the inequality of steam distribution, due to the angularity of

the connecting rod.

CONSTRUCTION OF THE SHIFTING LINK.

As usually

constructed for American locomotives, the link is a slotted block

curved to the arc of a circle, with a radius about equal to the

distance between the center of the driving-axle and the center

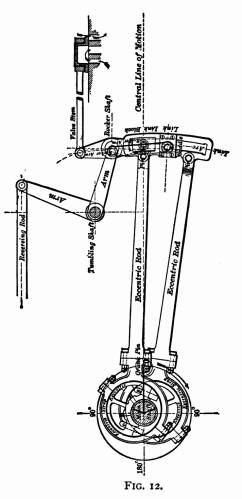

of the rocker-pin. The general plan of the link-motion is shown

in Fig. 12. Fitted to slide in the link-slot is the block which

encircles the rocker-pin. The eccentric-rods are pinned to the

back of the link; the forward eccentric-rod connecting with the

top, and the back-up eccentric-rod with the bottom, of the link.

Bolted to the side and near the middle of the link is the saddle,

which holds the stud to which the hanger is attached; this, in

its turn, connecting with the lifting arm, which is operated by

the reversing rod that enables the engineer to place the link

in any desired position. As usually

constructed for American locomotives, the link is a slotted block

curved to the arc of a circle, with a radius about equal to the

distance between the center of the driving-axle and the center

of the rocker-pin. The general plan of the link-motion is shown

in Fig. 12. Fitted to slide in the link-slot is the block which

encircles the rocker-pin. The eccentric-rods are pinned to the

back of the link; the forward eccentric-rod connecting with the

top, and the back-up eccentric-rod with the bottom, of the link.

Bolted to the side and near the middle of the link is the saddle,

which holds the stud to which the hanger is attached; this, in

its turn, connecting with the lifting arm, which is operated by

the reversing rod that enables the engineer to place the link

in any desired position.

ACTION OF THE LINK.

Regarded in its simplest form, the action of the link in full

gear is the same upon the valve movement as a single eccentric.

When the motion is working, as in the figure, with the eccentric-rod

pin in line with the rocker-pin, it will be perceived that the

movement can not differ much from what it would be were the eccentric-rod

attached to the rocker. Here the forward eccentric appears as

controlling the movement of the valve. Putting the link in back

motion brings the end of the backing eccentric-rod opposite the

rocker-pin, the effect being that the back-up eccentric then operates

the valve. When the link-block is shifted toward the center of

the link, the horizontal travel of the rocker-pin is decreased;

consequently, the travel of the valve is reduced; for, with ordinary

engines, the travel of the valve in full gear equals the throw

of the eccentrics, the top and bottom rocker-arm being of the

same length. The motion transmitted from the eccentrics, and their

means of connection with the link, make the latter swing as if

it were pivoted on a center which had a horizontal movement equal

to the lap and lead of the valve. The extremities of the link,

or rather the points opposite the eccentric-rods, swing a distance

equal to the full throw of the eccentric. The variation of valve-travel

that can be effected by the link, is from that of the eccentric

throw in full gear down to a distance in mid gear which agrees

with the extent of lap and lead. The method of obtaining these

various degrees of travel is by moving the link so that the block

which encircles the rocker-pin shall approach the middle of the

link.

When an engine is run with the lever in the center notch, the

supply of steam is admitted by the lead, opening alone. In full

gear the eccentric, whose rod-end is in line with the rocker-pin,

exerts almost exclusive control over the valve movement; but,

as the link-block gets hooked towards the center, it comes to

some extent under the influence of both eccentrics.

A thoughtful examination of Fig. 12 will throw light on the

reason why the proper position of a slipped eccentric can be determined

by the other eccentric when the engine is on the center. In the

cut, the crank-pin is represented on the forward center; and in

that position the eccentric centers are both an equal distance

in advance of the main shaft center. It will be evident now that

the valve must occupy practically the same position for forward

or back gear, as each of the eccentric-rods reaches the same distance

forward. Putting the motion in back gear would bring the back

up eccentric-rod pin to the position now occupied by the pin belonging

to the forward eccentric-rod.

VALVE-MOTTON OF A FAST PASSENGER LOCOMOTIVE.

Reducing the travel of the valve by drawing the reverse-lever

towards the center of the quadrant, and consequently the link-block

towards the middle of the link-slot, not only hastens the steam

cut-off, but it accelerates in a like degree every other event

of steam distribution throughout the stroke. To explain this point,

let us take the motion of a well-designed engine in actual service,

which has done good economical work on fast train running. The

valve-travel is five inches, lap one inch, no inside lap, lead

in full gear z inch, point

of suspension b inch back of

center of link.

EFFECT OF CHANGING VALVE-TRAVEL.

When this engine is working in full gear, the steam

will be freely admitted behind the piston till about eighteen

inches of the stroke, when cut-off takes place; and the release

or exhaust opening will begin at about twenty-two inches of the

stroke, giving four inches for expansion of steam. Now, if the

links of this engine are hooked up so that the cut-off takes place

at six inches of the stroke, the steam will be released at sixteen

inches of the stroke; and at that point compression will begin

at the other end of the cylinder.

WEAK POINTS OF THE LINK-MOTION.

This attribute which the link-motion possesses, of

accelerating the release and compression along with the cut-off,

is very detrimental to the economical operating of locomotives

that run slow. High-speed engines need the pre-release to give

time for the escape of the steam before the beginning of the return

stroke; and the compression is economically utilized in receiving

the heavy blow from the fast-moving, reciprocating parts, whose

direction of motion has to be suddenly changed at the end of each

stroke, and in helping to raise the pressure promptly in the cylinder

at the beginning of the stroke. A locomotive, on the other hand,

that does most of its work with a low-piston speed, would not

suffer from back pressure if the steam were permitted to follow

the piston close to the end of the stroke; and a very short period

of compression would suffice. If the engine, whose motion we have

been considering, instead of releasing at sixteen inches, could

allow the steam to follow the piston to twenty-two inches of the

stroke, after cutting off at six inches, a very substantial gain

of power would ensue. And this would be well supplemented by avoiding

loss of power, did compression not begin till within two inches

of the return stroke.

WHY DECREASING THE VALVE-TRAVEL INCREASES

THE PERIOD OF EXPANSION.

Increase of expansion follows reduced valve-travel,

from a similar cause to that which produces expansion when lap

is added to the edge of a slide-valve. When the valve is made

with the face merely long enough to cover the steam-ports, there

can be no expansion of the steam; for, so soon as the valve ceases

to admit steam, it opens the steam-port to the exhaust. When lap

is added, however, the steam is inclosed in the cylinder, without

egress for the time that it takes the lap to travel over the steam-port.

An arrangement of motion which will make the valve travel quickly

over the port, has a tendency to shorten the period for expansion;

while making the valve travel slowly over the port, has the opposite

effect, and protracts expansion. A valve with, say, five inches

travel, has a comparatively long journey to make during the stroke

of the piston; and the lap-edges will pass quickly over the steam-ports—much

more quickly than they will when the travel is reduced to three

inches. In a case of this kind, there is more than the mere reduction

of travel to be considered. Suppose the valve has one inch lap

at each end. When it stands on the middle of the seat, it has

a reciprocating motion of two and one-half inches at each side

of that point to make. At the beginning of the stroke, it has

been drawn aside one inch (we will ignore the lead), but still

has one and one-half inch to travel before it begins to return.

On the other hand, when the travel is reduced to three inches,

the valve has only one and one-half inch to travel away from the

center; and, one inch being moved to draw the lap over the port,

there only remains one-half inch for the valve to move before

it must begin returning. This entails an early cut-off; for the

valve must pass over the ports with its slow motion, and be ready

to open the port on the other end, before the return stroke. Thus

a travel of five inches draws the outside edge of the valve one

and one-half inch away from the outside of the steam-ports, three

inches travel only draws it one-half inch away, and a greater

reduction of travel decreases the opening in like proportion.

INFLUENCE OF ECCENTRIC THROW ON THE VALVE.

As reducing the travel of the valve diminishes the

port opening, a point is reached in cutting off early in the stroke

where the port opening is hardly any more than the port opening

due to the lead. This is what makes long steam-ports essential

for a successful high-speed locomotive. The best-designed engines

give an exceedingly limited port opening at short cut-offs, and

badly planned motion sometimes seriously detracts from the efficiency

of the engine, by curtailing the opening at the point where a

very brief time is given for the admission of steam. The magnitude

of the eccentric throw exerts a direct influence on the port opening

when cutting off early. A long throw tends to increase the opening,

while a short throw reduces it. The long-throw eccentric will

draw the valve farther away from the edge of the steam-port, when

admitting steam for the same point of cut-off, than a short-throw

eccentric will move its valve. For an ordinary 17 X 24 inch locomotive,

the throw of eccentric should not be less than five inches, unless

the engine is intended entirely for slow running. There are many

engines running with eccentric throw less than five inches, but

they are invariably slow unless the valve-lap is very short. With

an ordinary lap, an engine having an eccentric throw of 42 inches needs so much angular advance

to overcome the lap, and provide lead, that the rectilineal motion

of the eccentric is very meager at the beginning of the stroke.

That is, the center of the eccentric is traveling downward in

its circular path, which gives little motion to the valve, just

as the crank gives decreased motion to the cross-head when near

the centers.

HARMONY OF WORKING-PARTS.

Hitherto we have regarded the link as merely performing

the functions of transmitting the motion of the eccentrics to

the valves, with the additional capability of reducing the travel

at the will of the engineer. Otherwise, the motion of the link

is intensely complex; and its movements are susceptible to a multitude

of influences, which improve or disturb its action on the valve.

A good valve-motion is planned according to certain dimensions

of all the working-parts; and any change in their arrangement

will almost invariably entail irregularities upon the link's movement,

which will radically affect the distribution of steam. A link-motion

schemed for an eccentric throw of 42

inches will not work properly if the throw be increased

to five inches: a link with a radius of 57 inches can not be changed

with impunity for one of 60 inches. Any change in the position

of the tumbling-shaft or rocker-arms distorts the whole motion,

and any alteration in the length of the rods or hangers has a

similar effect. That the link may perform its functions properly,

all its connections must remain in harmony.

ADJUSTMENT OF LINK.

A very important feature of the link is its property

of adjustability, which serves to neutralize the distorting effect

of the connecting rod's angularity. As has already been explained,

the angularity of the main rod tends to delay the cut-off during

the backward stroke, while it is accelerated in the forward stroke.

With the ordinary length of connections, this irregularity would

seriously affect the working of the engine. But it is almost entirely

overcome by the link, which can be suspended in a way that will

produce equality for the period of admission and point of cut-off

for both strokes in one gear. Perfect equalization of admission

and cutoff for both gears has been found impossible with the link-motion;

and designers are generally satisfied to adjust the forward motion,

and permit the back motion to remain untrue. The point about the

link which exercises the most potent influence on adjusting the

cut-off, is the position of the saddle, or of its stud for connecting

the hanger. This stud is called the point of suspension. Raising

the saddle away from the center of the link will effect adjustment

of steam admission; but in locomotive practice the saddle is nearly

always located in the middle of the link, there being practical

objections against raising it. Equalization of steam distribution

is produced by placing the hanger-stud or point of suspension

some distance back of the center line of the link-slot, the distance

varying from 8 inch to d inch.

Moving the hanger-stud affects the link's movement in a way

that is equivalent to temporarily lengthening the eccentric-rod

during a portion of the piston-stroke. The length of the tumbling-shaft

arms, the length of hanger, the location of the rockers and tumbling-shaft,

the radius of link, and length of rods, all exercise influence

on the accurate adjustment of the valve-motion.

SLIP OF THE LINK.

In equalizing the valve-motion, and overcoming the

discrepancy of steam admission, due to the angularity of the connecting

rod by moving the link-hanger stud away from the center of the

slot, a new distortion is introduced. The link-block being securely

fastened to the bottom of the rocker-pin, moves in the fixed arc

traversed by that pin, which is nearly horizontal. The action

of the eccentric-rods on the link, on the other hand, forces the

latter to move with a sort of vertical motion at certain parts

of the stroke, making it slip on the block. Moving the hanger-stud

back tends to increase this slip, which will become excessive

enough to seriously impair the efficiency of the motion if not

kept within bounds by the designer. Where the slip is very great,

the motion will not be serviceable, a consideration which can

never be overlooked; for the block will wear rapidly, producing

lost motion, a very undesirable defect about any part of a link-gear.

With the long rods which prevail in locomotive practice, designers

have no difficulty in keeping the slip within practical bounds;

but with marine engines it is sometimes necessary to sacrifice

equality of steam admission to the reduction of the slip. The

greatest amount of slip is in full gear, and it diminishes as

the link-block is moved towards the center.

Placing the eccentric-rod pins back of the link-arc, as is

almost universally done in this country, has a tendency to make

the link slip on the block; and care has to be taken not to locate

these pins farther back than is actually necessary for other requirements

of the link-motion's adjustment. Auchincloss, who is a recognized

authority for designing of link-motion, gives four varieties of

alterations capable of reducing the slip when it is found too

great for a practicable motion.

His resorts are, either to increase the angular advance, reduce

the travel, increase the length of link, or shorten the eccentric-rods.

One, or a combination, of these methods may be adopted, as the

designer finds most convenient.

RADIUS OF LINK.

Among the constructing engineers who plan link-motion,

there is considerable diversity of opinion about what radius of

link helps to produce the best valve-motion. The distance between

the center of axle and center of lower rocker-pin may be accepted

as, approximately correct, although some designers slightly increase

beyond these points. On the other hand, the locomotives sent out

from a leading building establishment have the radius of link

drawn w inch per foot short

of the distance between the axle and rocker; and the claim has

been made, that the arrangement produces an excellent motion.

A committee of the American Master Mechanics' Association have

placed themselves on record on this subject by asserting that

the distance between the centers of axle and rocker-pin is the

proper radius for the link. That same committee recommended that

the link-motion should be planned to give as long a link radius

as possible, subject to the first-mentioned conditions.

It must be noted that the middle of the link-slot is the radius

arc. I knew of a case where the links for an altered locomotive

were finished out of the true radius through the edge of the slot

being taken as the radius-curve.

INCREASE OF LEAD.

Most of the men who are at all familiar with the valve-motion

are aware of the fact, that, with the shifting link, the lead

increases as the link is notched towards the center. Where the

valve has z inch lead in full

gear, it is no unusual thing to find it increase to a

inch lead opening at mid gear. The phenomenon is better known

than its cause is understood.

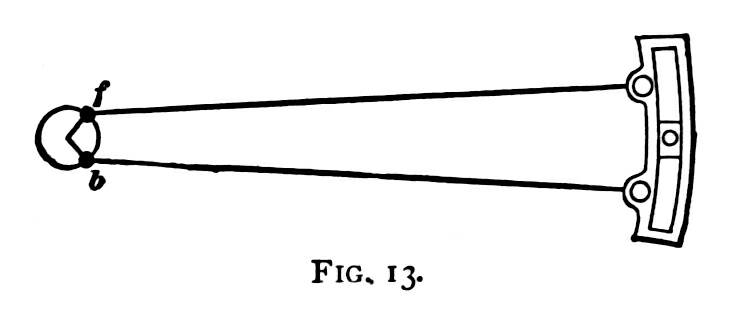

The relative positions of link and eccentric centers of an

engine, when the crank is on the forward center, are shown in

Fig 13;

the link being represented with the block in the center, which

represents mid gear. It will be observed that the centers of the

eccentrics f and b, from which the rods receive

direct influence, are both some distance ahead of the center of

the axle, the one above, the other below. The eccentric-straps

to which the rods are connected sweep round the eccentric circles,

and are controlled thereby. When the link is moved up or down,

each eccentric-rod pin, where it attaches to the link, describes

the arc of a circle with a radius drawn from its own eccentric.

If both rods were worked with a radius from the axle-center, the

link could be raised and lowered when the engine stands on the

dead center, without moving the rocker pins at all; but, under

the existing arrangement, the link is influenced directly by one

or other of the eccentrics, whatever position in the link the

block may stand. When the engine is standing on the forward center,

with the link in mid gear, as shown in Fig. 13, it will be readily

perceived that the block stands at its farthest point away from

the axle; for the rods are so placed to reach their greatest horizontal

distance ahead, and consequently in this position the lead opening

is greatest. If the link be now lowered, the backing eccentric-rod

will immediately begin to pull the link back: and, as the pin

of the forward eccentric-rod approaches the central line of motion,

it will also keep drawing the link back; so that, by the time

the link is in full gear, the lead opening will be considerably

reduced.

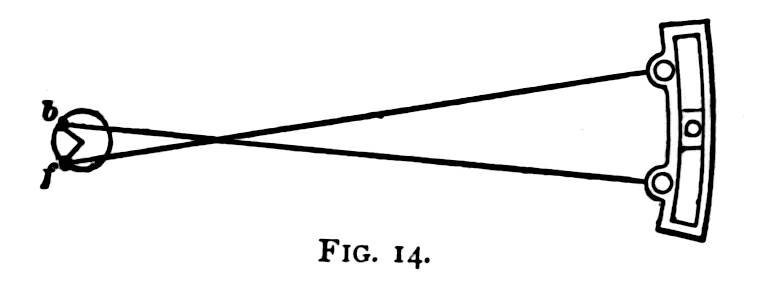

When the engine stands on the back dead center, as shown in

Fig. 14, the eccentric centers will be on the other side of the

axle, and the

eccentric-rods will be crossed. While in mid gear, the link-block

is drawn closer to the axle than it would be in any other position

of the link; and consequently the lead opening is greatest. If

the link be now lowered, the forward eccentric-rod will approach

its horizontal position, and consequently reaches farther on the

central line of motion, so it will push the link-block away from

the axle, thereby decreasing the lead. Pulling the link into back

gear has a similar effect. axle, and the

eccentric-rods will be crossed. While in mid gear, the link-block

is drawn closer to the axle than it would be in any other position

of the link; and consequently the lead opening is greatest. If

the link be now lowered, the forward eccentric-rod will approach

its horizontal position, and consequently reaches farther on the

central line of motion, so it will push the link-block away from

the axle, thereby decreasing the lead. Pulling the link into back

gear has a similar effect.

The tendency of a link-motion to increase the lead towards

the center is made greater by shortening the eccentric-rods. Increasing

the throw of eccentric inclines to accelerate the lead towards

the center, since it throws the eccentric centers farther apart.

For slow running, hard-pulling locomotives, where increase of

lead is a disadvantage, the tendency to increase the lead is sometimes

restrained in forward gear by reducing the angular advance of

the backing eccentric. This expedient is, however, not necessary

where proper care and intelligence have been bestowed in the original

design of the motion.

In studying this part of the valve-motion, a young machinist

or engineer will obtain valuable assistance by cutting a link

template out of a piece of pasteboard, and using strips of wood

as eccentric-rods. With these he can test on a drawing-board or

table the various positions of the link, and note, in a way that

is easily understood, the effect of changing the link into different

positions.

Table of Contents

| Contents Page

|