|

CHAPTER XXI.

THE WESTINGHOUSE AIR-BRAKE.

INVENTION OF THE WESTINGHOUSE ATMOSPHERIC

BRAKE.

IN this exacting age, the traveling public are much

more disposed to find fault with systems that do not provide against

fatalities resulting from human fallibility, than to commend the

perfection of appliances which annually save more lives than would

be lost in a sanguinary war. The Westinghouse brake has performed

this life-saving service, yet its great conserving merit has been

but feebly appreciated outside of railroad circles. During the

decade between 1860 and 1870, America became a reproach among

nations for the frequency and disastrous nature of its railroad

accidents. To-day fewer railroad travelers in America lose their

lives by accidents beyond their own control, than the travelers

in any country under the sun. The credit of this immunity from

fatal accidents is almost entirely due to the successful operation

of the Westinghouse and other brakes that followed the line suggested

by this invention.

DISTINCT CLASSES OF INVENTIONS.

Inventions may be divided into two distinct classes.

Far the more numerous class are those which effect improvements

on recognized appliances. The other is the rare and more valuable

class, to which belongs the original inventor who devises an entirely

new method for performing a desired operation. Among this class

of inventions may be noted Watt's separate condenser, which first

rendered the steam engine a commercial success; the multi-tubular

boiler of Nathan Read, which made a high-speed locomotive practicable;

and the airbrake of Westinghouse, which made fast traveling safe,

by putting the train speed under the control of the engineer.

BENEFITS CONFERRED ON TRAIN MEN BY GOOD

BRAKES.

To the traveling public the air-brake has proved a

source of satisfaction by assuring exemption from accidents, but

its greatest blessing has been conferred upon train men. Being

the greatest sufferers from railway accidents, their risks of

life and limb are greatly reduced; and the agonizing helplessness

that used to be so often experienced with trains that could not

be stopped in time to avoid a disaster, is almost unknown on our

well-managed roads. Mind has become victor in its conflict with

matter. When necessary, an engineer can run a train at a high

velocity over crowded lines without having to shut off steam within

a mile of each point where there may be another train obstructing

the track, or keep up his speed at the risk of his life. People

unacquainted with the inside operating of railroads have no idea

of the difficulties train men had to contend with in getting fast

trains over the road, before continuous brakes were supplied.

The train had to be run on schedule time, and all points where

trains might be expected had to be approached with care. This

meant reduced speed; and speed could not be reduced in short distances,

so the risk had to be taken of violating one rule to comply with

another.

ESSENTIAL PARTS OF THE WESTINGHOUSE AUTOMATIC

AIR-BRAKE.

The prominent features of the Westinghouse automatic air-brake

consist of the following leading parts:

An air-pump, placed on the locomotive, is operated by a steam

cylinder, which forces air into an iron drum or reservoir placed

under the deck, or in any other convenient part about the engine.

The air is compressed to the density considered necessary for

the kind of train the locomotive usually pulls.

In the cab, located conveniently to the hand of the engineer,

is the engineer's brake-valve, commonly called the "three-way

cock," which regulates the flow of air from the main reservoir

into the main brake-pipes for supplying the auxiliary reservoirs

with air. This valve applies the train-brakes by letting the air

escape from the main brake-pipes, and releases them by again admitting

the pressure of air into the pipes.

From the main reservoir, the main brake-pipe connects with

the engineer's valve, and thence along the train, supplying all

the brakes with the air required.

Under the floor of each car is fastened an auxiliary reservoir,

which holds a supply of air necessary for operating the brakes

on that car. So each car carries its own supply of air.

Connected with each car-truck is a brake-cylinder, in which

is operated a piston that applies the brake. The brake-levers

connect with the piston-rod in such a manner, that, when the piston

is forced out by the air-pressure, the brake is applied.

Attached to the auxiliary reservoir is the triple valve, whose

action connects the air-cylinder with the auxiliary reservoir.

THE AIR-PUMP.

When the air-brake was first invented, the distribution

of steam within the cylinder was effected differently from what

it is in modern pump-cylinders. The steam-valve consisted of a

double piston, the beads having ports on their edges which admitted

and released. the steam. This valve did not move up and down,

but received an oscillatory motion from a small auxiliary engine

placed on the top of the steam cylinder-head. The movements of

the auxiliary engine were regulated by a reversing-rod (popularly

known as a kicker-rod), working inside the main piston-rod. This

arrangement of steam distribution was somewhat complicated, and

liable to get out of order; and it was superseded by the differential

steam-valve movement now in use.

HOW THE AIR-PUMP WORKS.

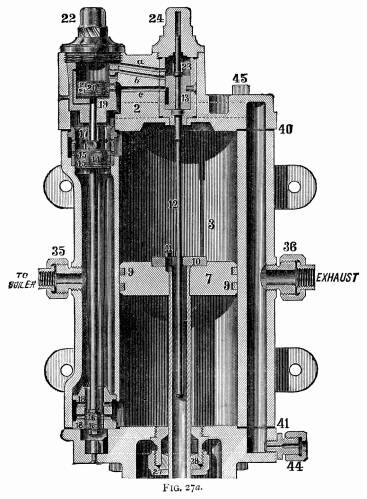

In Fig. 27a, steam enters from the boiler at the nipple

35, and fills the steam-space between the heads of the main piston-valve

15, 16, maintaining a constant pressure of steam there while the

pump is at work. The upper head of the main valve being of greater

area than the lower one, the tendency of the pressure is to raise

the valve. A downward movement of the valve is provided for by

a separate single-headed piston-valve 20, working in a cylinder

above the main valve. The reversing-rod 12 operates a slide-valve

13, which regulates the admission and release of steam for the

third piston.

In the cylinder

shown in the engraving, the main valve is down, so that steam

is passing into the lower end of the main cylinder. Two small

ports can be seen close to the piston-head 16, one above the other.

The upper port is open, and is the admission port: the lower port,

which is closed by the small piston, is for exhausting the steam.

The main piston 7 is on its upward stroke, and the upper exhaust

port seen above the piston-valve 15 is open, while the steam port

immediately below it is closed by the valve-piston in the same

way that the exhaust port is closed at the other end. When the

main piston 7 shall reach near the top of its upward stroke, the

plate 10 will strike on the projection on the reversing-rod, pushing

up the slide-valve Q. The upper edge of this slide-valve

will cut the steam off the passage a, and open the passage

b to the exhaust. This takes the steam away from the piston

20, and allows piston 15 to move upward, closing the exhaust-port,

and opening the upper steam-port. The same movement makes the

piston 16 close its steam-port, and open the exhaust. Piston 7

now begins to travel downward; and, when it reaches nearly to

the bottom of the cylinder, the plate 10 catches the knob on the

end of the reversing-rod, and pulls down the slide-valve 13 to

the position it holds in the engraving. Steam then rushes through

the passage a, and makes the piston 20 push down the main

valve. That completes the circle of the operations in the steam

cylinder. In the cylinder

shown in the engraving, the main valve is down, so that steam

is passing into the lower end of the main cylinder. Two small

ports can be seen close to the piston-head 16, one above the other.

The upper port is open, and is the admission port: the lower port,

which is closed by the small piston, is for exhausting the steam.

The main piston 7 is on its upward stroke, and the upper exhaust

port seen above the piston-valve 15 is open, while the steam port

immediately below it is closed by the valve-piston in the same

way that the exhaust port is closed at the other end. When the

main piston 7 shall reach near the top of its upward stroke, the

plate 10 will strike on the projection on the reversing-rod, pushing

up the slide-valve Q. The upper edge of this slide-valve

will cut the steam off the passage a, and open the passage

b to the exhaust. This takes the steam away from the piston

20, and allows piston 15 to move upward, closing the exhaust-port,

and opening the upper steam-port. The same movement makes the

piston 16 close its steam-port, and open the exhaust. Piston 7

now begins to travel downward; and, when it reaches nearly to

the bottom of the cylinder, the plate 10 catches the knob on the

end of the reversing-rod, and pulls down the slide-valve 13 to

the position it holds in the engraving. Steam then rushes through

the passage a, and makes the piston 20 push down the main

valve. That completes the circle of the operations in the steam

cylinder.

HOW THE AIR-END OPERATES. HOW THE AIR-END OPERATES.

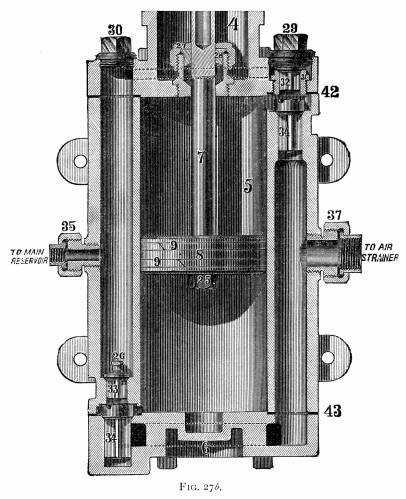

The operation of the air part of the pump is very simple.

While the main piston (Fig. 27b), which is on the same rod as

the piston of the steam cylinder, is moving upward, it is forcing

the air out of the upper end of the cylinder up under the discharge-valve

32, and away through the proper passages to the main reservoir.

At the same time the lower end of the cylinder is being filled

with air drawn through the lower receiving-valve 34. During the

downward stroke of the piston, the air will be delivered through

the valve 33, and the upper part of the cylinder filled by air

received through the upper valve 34.

AIR-PUMP DISORDERS.

An engineer who does not understand the principles

of a locomotive's action, is not likely to prove a valuable runner.

The men who are most successful in getting trains over the road

with solar regularity; the men who make the best records on the

mileage sheets for economy in fuel and in lubricants; who are

lightest in repairs, yet keep their engine going longest, —

are those who comprehend the functions of every portion of the

engine, and what relation the various parts bear to each other.

With this knowledge clearly established in the mind of the runner,

his power to detect any thing wrong with his engine becomes instinctive.

Trifling defects, which neglect would develop into serious disabilities,

are rectified in time, and the whole engine is maintained in smooth

working-order by the harmony of its individual sections. The mere

stopper and starter is losing his hold on the locomotive service.

When he drops off entirely, our mileage for each dollar expended

will be decidedly increased.

The principles which apply to the running of a locomotive are

equally applicable to the management of an air-brake, with all

its perfected connections. This apparatus can not be properly

managed unless the man who works it knows something about its

action.

PUNY DIFFICULTIES VANQUISH THE IGNORANT

ENGINEER.

A great many engineers who run passenger trains, and

take an intelligent interest in the working of the locomotive,

whose technicalities they have thoroughly mastered, display no

desire whatever to understand the air-brake, and are perfectly

contented with its action so long as it will stop the train. The

air-pump, so wonderfully interesting to those who understand its

movements, receives no more attention than is necessary to keep

it going so that the required air-pressure is maintained. They

know how to start and stop the machine, and they oil it regularly;

but these are the limits of their attentions. Should the pump

happen to stop working, the cause is mysterious, like many other

mysteries; and the natural remedy suggested, is to hit the thing

on the head with a monkey-wrench. Should it not respond to this

treatment by renewed action, the hand-brakes are resorted to for

the rest of the journey; and the roundhouse foreman or machinist

is required to do the head, work which locates the trouble.

A belief prevails among men who labor principally with their

hands, that laziness is exclusively physical. This is a mistake.

It is a psychological fact, well known to metaphysicians, that

mental laziness is prevalent enough to dwarf the minds of half

the human race. Men who would willingly work with their hands

during half their leisure time to keep their engines in proper

condition for running, have to be driven, by fear or jealousy,

before they will force their mental faculties to do trifling labor

in a new channel.

CAUSES THAT MAKE BRAKES INOPERATIVE OFTEN

EASILY REMEDIED.

Any engineer of ordinary intelligence, who will spend

one hour a day for two weeks studying up the Westinghouse instruction

book, will understand the brake so well, from the pump to the

hind end of the train, that any imperfection happening to its

working will be as readily located as an ordinary defect in a

locomotive. Yet it is an intensely hard matter to induce men running

passenger engines to go through this trifling mental exercise.

The consequence is, that the brake sometimes becomes inoperative

from causes so slight that men should be ashamed to report them;

and they, would be so if they only comprehended how small a mole-heap

became their mountain. I knew a case where all the train men —

that is to say, engineer, fireman, conductor, baggageman, and

brakemen wrestled for twenty minutes over a triple valve, trying

to find out how to cut the air off a car; and, when the crowd

was vanquished, a colored porter came, and showed them how the

thing was done. This was on a road where straight air was generally

used. One day some winters ago, a passenger train on the road

I worked for was delayed an hour or more at a station, waiting

for something, When the engineer tried to start the air-pump,

it would not work. He fumed and fussed over it for fifteen minutes,

gave it a liberal dose of copper hammer medicine, and saturated

it with oil, but all to no purpose. It would not pump a pound

of air, so the old-fashioned Armstrong was called into operation.

In the course of its journey, this train had to pass the round-house

at headquarters ; and the engineer stopped to see if his pump

could be given some quick remedy. I happened to be the doctor

consulted. On learning the particulars of how the pump stopped

working, I set fire to a piece of greasy waste, and held the flame

to the check-valve of the air-drum; and the pump went right to

work. All the trouble was, that the check-valve was frozen in

its seat. I felt sorry for that engineer, he appeared to be so

thoroughly ashamed and crestfallen at being baffled by such a

small trouble.

CARE OF THE AIR-PUMP.

To run an air-pump successfully, the first requisite

is that it should be managed intelligently, and its wants attended

to regularly. An air-pump consists of numerous moving parts, which

should operate with the least possible amount of friction: consequently,

it is important that the machine should be properly lubricated,

not deluged with grease for ten minutes, and then run on the interest

of the excess for two hours, but sparingly furnished with clean

oil which will keep the moving parts moist all the time. To accomplish

this, the feeding-cup must be kept in proper working-order, so

that it will pass the oil regularly. I have found a leading cause

for air-pumps working unsatisfactorily to be in the intermittent

feeding of the oil-cups. Some dirt gets into the cup, obstructing

its action, and greater opening is given to make it feed; then

the oil goes through by spasms, and the pump works irregularly;

for at one time the steam-piston is churning the oil, and again

it is working dry. There is also a common abuse of the oilcan

when any thing goes wrong with the pump; for some men will then

drench it with oil, expecting that to make it work smoothly. Permanent

injury is often done in this way, especially where inferior oils

are used, which frequently contain mineral substances in suspension.

This solid matter is separated from the oil by the heat, and settles

in the small passages, filling them up by degrees till eventually

there is no channel left for the steam to pass through to reverse

the steam-valve; so the pump stops. I once saw a runner trying

to doctor a sick pump by pouring the stickiest kind of gummy valve-oil

into an air-cylinder. He gave the thing its quietus, as other

poor doctors sometimes do with their patients.

PUMP PACKING.

The stuffing-box packing is not generally supposed

to exercise an important effect on the action of an air-pump;

yet I have seen cases where irregular action of the pump, and

serious loss of air, resulted from bad packing. Soapstone and

asbestos, and other substances that become compact and rigid when

cold, are unsuitable for packing the air end of a pump. After

a little use, material of this kind becomes so hard that no amount

of screwing of the gland will make it tight; and the greater part

of the air at that end of the pump escapes through the stuffing-box

instead of passing into the drum.

HOW STEAM PASSAGES GET CHOKED.

Around the bushings of the cylinder, where the small

reversing piston 20 works, are diminutive steam passages, very

liable to get stopped up when foreign matter is attempted to be

run through the cylinder. Such matter is occasionally introduced

in various ways. When rubber gaskets are used in the pipe connections

leading to the cylinder, the rubber often peels off in shreds,

or breaks off in small pieces, which lodge around the bushing

in the passages, producing harassing annoyance. So soon as those

passages get obstructed, or reduced below their correct size,

the pump begins to work badly. Machinists not well versed in the

mysterious ways of air-pump disorders will now take that pump

apart, and find nothing the matter. Subsequent proceedings depend

upon the nature of the man who has the job in hand. If the machinist

be of a conservative disposition, he will put the apparatus together

again without making any alteration, and perhaps will relieve

his mind by expressing a belief that the engineer does not know

when an air-pump is in good shape. Another machinist, of a more

enterprising stamp, must find something to change, so he lengthens

or shortens the reversing valve-rod 12 (a favorite resort of small-knowledge

tinkers), which gives the pump the coup de grâce; and

it has to be over. hauled by a competent machinist before it again

supplies the air to stop a train. This competent man goes direct

to the root of the trouble. Skill in this particular line of work

convinces him, after an examination, that the moving parts require

no repairs; and knowledge begotten of experience, supplemented

by sound sense, directs him where to look for the cause of defective

operation.

SAGACITY NEEDED IN REPAIRING AIR-PUMPS.

Men who meet with good success in repairing air, pumps,

and in determining, from the action of the pump the probable cause

of defect, have to do a great deal of deep and sagacious thinking.

Sometimes a defect, simple enough in itself, is extremely difficult

to locate, because it belongs to the unexpected order of occurrences.

Here was an instance. Some small jobs had been done one day

to the steam cylinder of a pump which had not been working quite

satisfactorily. When they tried to start it, after being put together,

the pump would not work at all. The machinist who did the job,

an eminently competent man at such work, took the machine apart

again, but could detect no defect or maladjustment about it. The

steam cylinder, with all its valves and rods and bushings, was

critically examined: the air-pump, with all its connections, got

a thorough inspection to no purpose. When an ordinary man goes

through the patient, thoughtful labor needed for an examination

of this kind, and finds nothing wrong, he is apt to get discouraged,

and confess himself beaten. This man did not recognize the word

beaten as applied to his work. He reasoned, "This pump would

work if it were all right. It will not work, so something must

be wrong." After exercising more patience and perseverance,

he discovered that the bushing 23 of the reversing valve (usually

called the kicking-rod valve) had become loose, and, when the

cap was screwed down, it twisted the bushing round, and closed

the passages that lead steam to the reversing piston. There are

small grooves round the sides of the small steam passages to provide

for the bushings being moved a little, but these grooves had become

gummed up so that they failed to serve their purpose of keeping

the ports open.

GRADUAL DEGENERATION OF THE AIR-PUMP.

The working and stationary parts within the cylinders

of the air-pump are adjusted with nice exactness; and, when they

remain in their normal condition, the pump works smoothly, and

compresses air rapidly. When wear, or any other cause, alters

the dimensions of these parts, the effect immediately becomes

apparent in unsatisfactory working of the whole machine. Rods

are adjusted so that valves or pistons shall cover and uncover

steam passages, and no superfluous movement is provided for. The

passages are so small that all the steam they convey is needed

for the work of reversing the motion; and if from any cause the

valve or piston only partly uncovers the opening, the necessary

volume of steam does not get through. A close observer of the

pump's action can, day by day, perceive the gradual degeneration

due to wear. Wear of the steam-cylinder connections is generally

indicated by reduced power. The pump will not do its work satisfactorily,

and has difficulty in keeping up the pressure of air. This deterioration

continues till the pump will stop, unless its decay gets arrested

by repairs. When the valves of the air-pump are in correct order

for doing good work, the discharge-valves 32 and 33 have Z of an inch, and the suction-valves

34 8", lift. The continual

tapping of these valves on their seats has a tendency to wear

out valves and seats, making the lift greater than what is desirable.

Any material increase of lift for the discharge-valve has a most

injurious effect upon the motion of the pump, especially if the

suction-valve should happen to be leaky. Then the movement of

the pistons will become fluctuating, and subject to frequent stoppages.

The up-and-down motion of the piston is of a jerky character,

that makes the beholder suppose the thing is uncertain which way

to go. Deterioration of air-valves is not, however, the only cause

for that jerky motion so often observed in bad working pumps.

A bent reversing valve stem (kicker-rod) acts on the reversing

valve with oblique pull and thrust, which tend to move it away

from the seat, letting the steam pass the wrong way. A broken

main steam-valve ring has a similar effect; for the steam passes

to the wrong end of the valve, destroying its equilibrium; and

there is nothing decisive about its reversal, or about its motion

after it is reversed. Its action resembles the movements of a

vacillating human being. It does not want to go in that direction,

but goes, then keeps trying to change its mind during the rest

of the journey. Obstructed steam passages will sometimes cause

indecisive action of the pump before it gets bad enough to stop

it altogether.

When one of the exhaust ports begins to get filled up sufficiently

to interfere with the action of the pump, the effect will be that

the main piston will very slowly approach the end where the trouble

is, and then make the opposite stroke with a quick motion. The

contracted passage leaves some steam in the cylinder which is

compressed, causing slow movement, and the compressed steam helps

to give velocity to next stroke.

CAUSES THAT MAKE A PUMP POUND.

Pounding on the heads is a somewhat common attribute

of degenerated air-pumps. Broken or badly worn air-valves very

often cause the pump to pound. If the trouble should happen to

be in the upper air-valve, it will demonstrate its disorder by

causing pounding on the upper head; and the lower valve's malady

will cause pounding on the lower head. When a pump is suffering

from indecisive motion, or is pounding, and the machinist does

not feel certain about where the trouble lies, he may safely examine

the condition of the air-valves, —for they can be easily

reached,— and in a great many cases the defect will be found

there. Wear of the pin whereon the bottom of the main valve-rod

rests, or of the rod itself, will induce pounding on the tipper

head by the main piston.

I have known of a disastrous effect being produced on a pump

by putting a new gasket, which proved too thick, on the upper

head. It was the thinnest copper that could be found, but it perceptibly

lengthened the upper end of the cylinder so that the bottom knob

on the reversing stem struck the reversing plate on the main piston

before that action was due. On several occasions I have had air-pumps

reported to be working badly, when all the trouble lay in the

air-strainer being partly choked up by floating vegetable matter

that had been sucked in with the air, and failed to pass through

the meshes. In another case we had much difficulty in locating

the defect, with a pump that absolutely refused to work. The boiler-makers

had been working in the smoke-box, and by some means the end of

the exhaust-pipe got solidly stopped up with cinders. As none

of us had come across that particular cause of obstruction before,

we expended a good deal of labor searching for the trouble before

we thought to disconnect the exhaust-pipe from the pump.

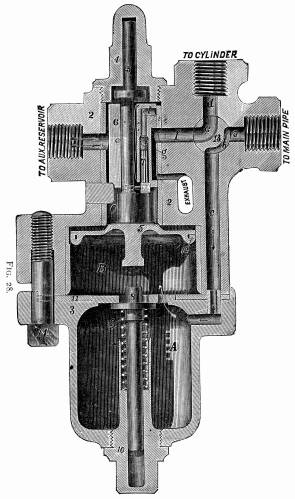

THE TRIPLE VALVE. THE TRIPLE VALVE.

This is the part whose operation gives the brake its automatic

action. Those who have opposed this form of brake have made great

objection to the complicated nature of the triple valve. But some

familiarity with the device shows that it is far from being complex,

considering the functions it performs. It is merely a piston-valve

carrying a slide-valve along with it.

The arrangement of the parts of the triple valve is shown in

Fig. 28.

The triple valve has a piston 5, working in the chamber B,

and carrying with it the slide-valve 6. Air enters from the main

pipe through the four-way cock 13 into the drain-cup A,

and passes to the chamber B, forcing the piston up, and

uncovering a small feeding-groove in the upper part of the chamber,

which permits air to flow past the piston into the auxiliary reservoir,

while, at the same time, there is an open communication from the

brake-cylinder to the atmosphere through the passages d, e,

f, and g. Air will continue to flow into the auxiliary

reservoir until it contains the same pressure as the main brake-pipe.

ACTION OF THE TRIPLE VALVE.

To apply the brakes with their full force, the compressed

air in the main brake-pipe is permitted to escape, when the greater

pressure in the auxiliary reservoir forces the piston 5 down below

the feeding-groove, thus preventing the return of air from the

reservoir to the brake-pipe. As the piston descends, it moves

with it the slide-valve 6, so as to permit air to flow directly

from the auxiliary reservoir into the brake-cylinder, which forces

the pistons out, and applies the brakes. The brakes are released

by again admitting pressure into the main brake-pipe from the

main reservoir; which pressure, being greater than that of the

auxiliary reservoir, forces the piston 5 back to the position

shown in the engraving, recharges the reservoir, and at the same

time permits the air in the brake-cylinders to escape.

To apply the brakes gently, a slight reduction is made in the

pressure in the main brake-pipe, which moves the piston down slowly

until it is stopped by the graduating spring 9. At this point,

the opening l in the slide-valve is opposite the port f,

and allows air from the auxiliary reservoir to feed through a

hole in the side of the slide-valve, and through the opening l

into the brake-cylinder. The passage l is opened and closed

by a small valve 7, which is attached to, and moves with, the

piston 5, provision being made for a limited motion of these parts

without moving the valve 6. When the pressure in the auxiliary

reservoir has been reduced by expanding into the brake-cylinder

until it is the same as the pressure in the main brake-pipe, the

graduating spring pushes the piston up until the small valve 7

closes the feed opening l. This causes whatever pressure

is in the brake-cylinder to be retained, thus applying the brake

with a force proportionate to the reduction of pressure in the

brake-pipe.

TO PREVENT CREEPING ON OF BRAKES.

To prevent the application of the brakes, from a slight

reduction of pressure caused by leakage in the brake-pipe, a semicircular

groove is cut in the body of the car-cylinder, nine-sixtyfourths

of an inch in width, five-sixtyfourths of an inch in depth, and

extending so that the piston must travel three inches before the

groove is covered by the packing leather. A small quantity of

air, such as results from a leak, passing from the triple valve

into the car-cylinder, has the effect of moving the piston slightly

forward, but not sufficiently to close the groove, which permits

the air to flow out past the piston. If, however, the brakes are

applied in the usual manner, the piston will be moved forward,

notwithstanding the slight leak, and will cover the groove. It

is very important that the groove shall be three inches long,

and shall not exceed in area the dimensions given above. Heretofore

leakage valves have been used, and also a leakage hole. These

leakage holes have been found to be too uncertain in their operation;

and consequently it is recommended that these holes should be

closed, and the grooves in the cylinders substituted, as rapidly

as possible.

When the handle of the four-way cock 13 is turned down, there

is a direct communication from main brake-pipe to the brake-cylinder,

the triple valve and auxiliary reservoir being cut out; and the

apparatus can be worked as a non-automatic brake, by admitting

air into the main brake-pipe and brake-cylinder, to apply the

brakes. When from any cause it is desirable to have the brake

inoperative on any particular car, the four-way cock is turned

to an intermediate position, which shuts off the brake-cylinder

and reservoir, leaving the main brake-pipe unobstructed to supply

air to the remaining vehicles.

The drain-cup A collects any moisture that may accumulate,

and is drained by unscrewing the bottom nut.

HOW TO APPLY AND RELEASE THE BRAKE.

The brakes, as has been explained, are applied when

the pressure in the brake-pipe is suddenly reduced, and released

when the pressure is restored.

It is of very great importance that every engineer should bear

in mind that the air-pressure may sometimes reduce slowly, owing

to the steam-pressure getting low, or from the stopping of the

pump, or from a leakage in some of the pipes when one or more

cars are detached for switching purposes, and that in consequence

it has been found absolutely necessary to provide each cylinder

with the leakage groove already referred to, which permits a slight

pressure to escape without moving the piston, thus preventing

the application of the brakes, when the pressure is slowly reduced,

as would result from any of the above causes.

This provision against the accidental application of the brakes

must be taken into consideration, or else it will sometimes happen

that all of the brakes will not be applied when such is the intention,

simply because the air has been discharged so slowly from the

brake-pipe that it only represents a considerable leakage, and

thus allows the air under some cars to be wasted.

It is thus very essential to discharge enough air in the first

instance, and with sufficient rapidity, to cause all of the leakage

grooves to be closed, which will remain closed until the brakes

have been released. In no case should the reduction in the brake-pipe

for closing the leakage grooves be less than four or five pounds,

which will move all pistons out so that the brake-shoes will be

only slightly bearing against the wheels. After this first reduction,

the pressure can be reduced to suit the circumstances.

On a long train, if the three-way cock be opened suddenly,

and then quickly closed, the pressure in the brake-pipe, as indicated

by the gauge, will be suddenly and considerably reduced on the

engine, and will then be increased by the air-pressure coming

from the rear of the train: hence it is important to always close

the three-way cock slowly, and in such a manner that the pressure,

as indicated by the gauge, will not be increased; or else the

brakes on the engine and tender, and sometimes on the first one

or two cars, will come off when they should remain on. It is likewise

very important, while the brakes are on, to keep the three-way

cock in such a position that the brake-pipe pressure can not be

increased by leakage from the main reservoir; for any increase

of pressure in the brake-pipe causes the brakes to come off.

On long down grades, it is important to be able to control

the speed of the train, and at the same time to maintain a good

working pressure. This is easily accomplished by running the pump

at a good speed, so that the main reservoir will accumulate a

high pressure while the brakes are on. When, after using the brake

some time, the pressure has been reduced to sixty pounds, the

train pipes and reservoirs should be recharged as much as possible

before the speed has increased to the maximum allowed. A greater

time for recharging is obtained by considerably reducing the speed

of the train just before recharging, and by taking advantage of

the variation in the grades.

There should not be any safety-valve or leaks in the main reservoir,

otherwise the necessary surplus pressure for quickly recharging

can not be obtained.

To release the brakes with certainty, it is important to have

a higher pressure in the main reservoir than in the main pipe.

If an engineer feels that some of his brakes are not off, it is

best to turn the handle of the three-way cock just far enough

to shut off the main reservoir, and then pump up fifteen or twenty

pounds extra, which will insure the release of all of the brakes;

all of which can be done while the train is in motion.

For ordinary stops, great economy in the use of air is effected

by, in the first instance, letting out from eight to twelve pounds

pressure while the train is at speed, taking care to begin a sufficient

distance from the station.

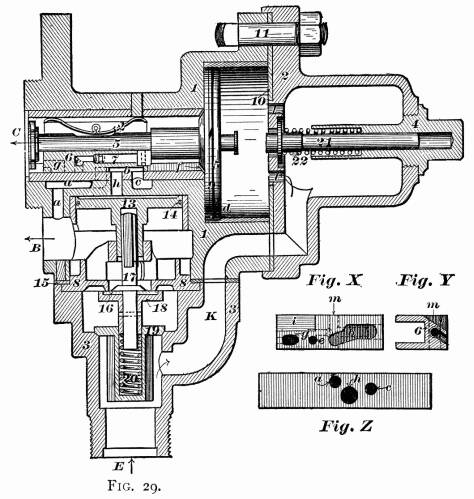

THE QUICK-ACTION VALVE. THE QUICK-ACTION VALVE.

When the application of air-brakes to freight trains

began to be a recognized necessity, it was found that the common

automatic brake was too slow in its action for handling a train

of fifty cars smoothly. The required quickness of action was provided

by Mr. Westinghouse in the invention of the Quick-action Triple

Valve, illustrated in Fig. 29.

This triple valve stands horizontally instead of vertically

as the old one is set, and it retains all its former features,

while those that are added are improvements. The casing of the

triple valve has three branches, C, B, and E

(seen in Fig. 29), connected respectively to the auxiliary

reservoir, the brake-cylinder, and the train-pipe. Branch E

has access by the passage K and openings ll

with a cylinder in which is the piston-valve 5. The opposite side

of this piston is in direct connection with the reservoir through

the opening C, and, when the parts are in the position

shown, compressed air from the train-pipe can flow past the piston

5, through the grooves d and f, until the pressure

in the reservoir is equal to that in the train-pipe. During the

time the interior of the brake-cylinder is connected to the atmosphere

through the branch B, the passage a, the port a

(Fig. Z, and also shown in dotted lines in Fig. 29), the

cavity b (Figs. 29 and X) of the slide-valve 6,

and the port c which emerges into the open air. If now

the pressure in the train-pipe be slightly reduced by opening

the engineer's valve, the piston 5 will be moved to the right

by the expansion of the air in the reservoir, but under ordinary

circumstances it will only move through half of its available

travel, in consequence of the pressure in the reservoir being

reduced to that in the train-pipe by a part of the air rushing

into the brake-cylinder in the following way: The rod of the piston

5 passes through the slide-valve 6, the connection between the

two being so made that the piston can move a small distance without

moving the valve. When the piston first moves, it carries with

it the "graduating" valve 7 seated in a recess in the

slide-valve, and allows the air to gain access through the passage

m (Fig. X) to the port e. The continued movement

of the piston carries the valve to the right until the port e

comes opposite to the port a, which is first shut off

from the atmosphere. The air then flows from the auxiliary reservoir

to the brake-cylinder and applies the brakes, but immediately

its pressure has fallen slightly below the pressure in the train-pipe,

the piston 5 moves slightly back and closes the valve 7, cutting

off the air-supply. If now the pressure in the train-pipe is again

slightly reduced, the valve 7 will be opened again by the piston,

and in this way, by repeated applications, the brakes can be applied

gradually up to the maximum force which would be possible when

the pressure is equalized in the cylinders and auxiliary reservoirs.

APPLYING THE QUICK ACTION.

When the engineer desires to apply the brakes rapidly

and strongly, then the new part is brought into action. By opening

his valve wide the pressure in the train-pipe will be so far reduced

that the piston 5 will move to the extreme limit of its travel

and will seat itself against the leather ring 10. The corner of

the slide-valve being removed at i (Fig. X) opens

port h (Fig. Z), and brings port g over the

port a. Air from the reservoir passing through the port

h acts on the piston 13, forcing it down, and at the same

time opening the valve 18. Immediately this happens, the check-valve

19 is opened by the pressure below it, and there is a clear passage

from the train-pipe into the brake-cylinder. There is also a passage

from the reservoir through the ports g and a, but

as its cross-section is small, compared with that of the opening

through the valves, the train-pipe has time to relieve itself

before the accumulation of pressure at B shuts the check-valve

19 and prevents the air blowing back into the train-pipe. After

the engineer has accomplished his object the brakes are released

in the usual way by connecting the train-pipe to the main reservoir

on the engine or tender. The pressure moves back the piston 5

and slide-valve 6 to the position shown. The cavity b connects

the passage h to the atmosphere; the piston 13 is raised

by the cylinder pressure beneath it, and the valve 18 by the spring

20. The air in the brake-cylinder exhausts through the passage

a and cavity b into the atmosphere, and the springs

in the brake-cylinder return the brake-pistons and take off the

brake-shoes, and the reservoir is again recharged through the

groove d and f.

ENGINEER'S BRAKE AND EQUALIZING-DISCHARGE

VALVE.

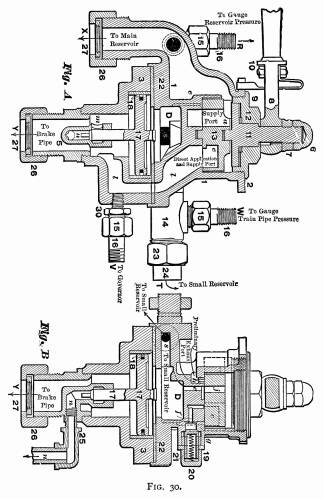

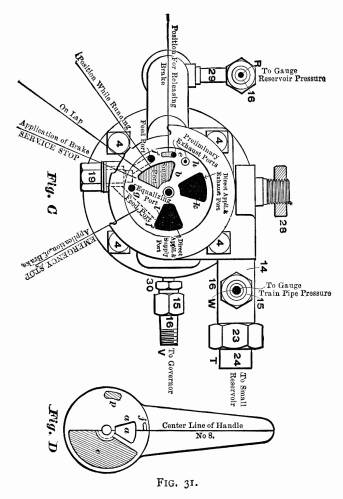

The purpose of the valve illustrated in Figs. 30 and

31 is to put in the hands of the engineer an apparatus that would

insure a more uniform application of brakes through the entire

length of a long train than was practicable with the old forms

of engineer's valve. It admits of easy and gradual reductions

of air, and prevents the sudden reduction of pressure from the

forward cars that so often led to the release of front brakes

caused by the rush of air through the pipes.

By preparing a diagram similar to Fig. D, representing

the rotary-valve 13 and handle 8, of tracing cloth or other

transparent material, cutting the ports a and j

out of the diagram on their boundary lines to show through

openings, and then reversing same and placing it upon the

seat of the valve, Fig. C, where it may be rotated at will

on its center, the explanation following will be made clear.

By reference to cuts of the valve Figs. 30 and 31, it

will be seen that movement of the handle 8, on which is located

a spring 9 for guiding it to position, operates "rotary valve"

13 upon its seat, opening and closing the various ports

as required.

When the handle 8 is in "position for releasing brake"

air pressure from the main reservoir, entering the brake-valve

at X, passes through "supply ports" a

and b, thence upward into cavity c, in the under

surface of the rotary valve 13, then through "direct application

and supply port" l to the train-pipe at Y.

While yet in this position, port j in the rotary valve

and port e in its seat are in communication, and air passes

into chamber D above piston 17, thence through port

s to a small reservoir, which is usually suspended under

the right running board of the engine, pipe connections being

made therewith at T. This reservoir serves the, purpose

of increased volume of space to chamber D.

The handle 8 now being placed in "position while running,"

direct communication between the train-pipe and main reservoir

ceases, and port j is brought opposite feed-port f

through which main reservoir pressure now passes to the under

side of the "feed-valve" 21, which latter is held to

its seat by "feed-valve spring" 20 having a resistance

of about twenty pounds. When this additional pressure is accumulated

in the main reservoir, "feed-valve" 21 is forced open,

the pressure passing thence through "feed-port" f1

to port l and the train-pipe, while train-pipe pressure

is maintained in chamber D through port l, cavity

c, and "equalizing port" g, thus equalizing

the pressure on top and under piston 17, the stem of which, forming

a valve, is seated in the position shown in "bottom cap"

5, and permits the escape of air from the train-pipe to the atmosphere

through ports m and n when raised from its seat.

When applying brakes for ordinary or station stops, move handle

8 to "on lap" position. This blanks all ports in the

rotary valve and seat. Then moving the valve handle to the position

"application of brake, service stop," the small exhaust

cavity p in the lower surface of the rotary valve 13 establishes

communication between the two "preliminary exhaust ports"

e and h, the latter leading to the atmosphere, and

after discharging about eight pounds pressure as shown by the

gauge, restore the handle to "on lap" position. This

preliminary discharge of air from chamber D will cause

the piston 17 and its stem to rise, which operation is followed

by a discharge of air from the train-pipe to the atmosphere through

ports m and n applying the brakes gently. This discharge

of air from the train-pipe continues after the valve handle is

carried to "on lap" position (gradually equalizing train-pipe

pressure) and until the train-pipe pressure has been reduced slightly

lower than that yet remaining in the chamber above the piston,

when the latter is forced downward, and its stem to its seat,

closing the outlet n, and preventing the further escape

of air, until the operation is repeated, which may be necessary

to apply the brakes with the desired degree of force.

To throw off brakes, push handle 8 to "position for releasing

brakes," causing the excess air-pressure in main reservoir

to be discharged into the train-pipe, insuring their prompt and

certain release.

For an "emergency" application of brakes, push the

handle to the extreme right, to position "application of

brake, emergency stop." This operation establishes direct

communication between the train-pipe and the atmosphere, through

the "direct application and supply port" l, cavity

c, and the "direct application and exhaust port"

k, applying the brakes with full force instantly.

When handling trains on down grades, the handle should be kept

in "full release" position, except when applying brakes,

which will insure the full and prompt recharging of auxiliary

reservoirs under cars.

PUMP GOVERNOR. PUMP GOVERNOR.

This is an important attachment which ought to be connected to

all air-brake pumps. It not only prevents the carrying of an excessive

air-pressure by the engineers, which often results in the sliding

of the wheels, but it also causes the accumulation of a surplus

of air-pressure in the main reservoir, while the brakes are applied,

which insures the release of the brakes without delay. It also

limits the speed of the pump, and consequently the wear.

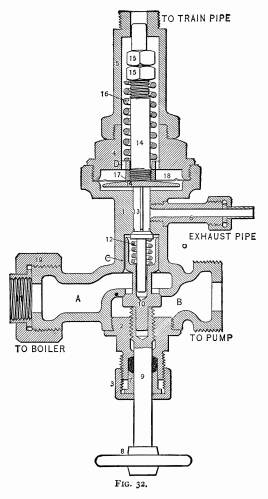

The pump governor is shown in Fig. 32, the object of which

is to automatically cut off the supply of steam to the pump when

the air-pressure in the train-pipe exceeds a certain limit, say

seventy pounds.

The operation of this governor is as follows: the wheel 8 is

screwed down so as to permit the valve 10 to be unseated by the

excess of pressure on the upper side of the valve, permitting

steam to pass through the openings A and B to the

pump. A connection is made from the train-pipe to the upper end

of the governor, and the compressed air passes around the stem

14 to the upper side of the diaphragm plate 18, which is held

to its position by the spring 16, which latter is of sufficient

strength to resist a pressure of, say, seventy pounds per square

inch on diaphragm. As soon as the air-pressure on the diaphragm

18 exceeds this amount, it forces the diaphragm down, unseating

the valve 13, and allowing the steam on the upper side of the

valve 10 to escape through the exhaust 6, which causes an excess

of steam-pressure on the lower side of the valve 10, forcing the

valve against its seat, and cutting off the supply of steam to

the pump.

When the pressure in the train-pipe is diminished by applying

the brakes, the diaphragm is restored to the position shown by

the action of the spring 16. The valve 13 is seated by the spring

12; and the steam pressure, passing through the port C,

accumulates on the upper side of the valve 10, forcing it down,

and opening the passage for steam to the pump until the air-pressure

is again restored to the required limit of seventy pounds.

Table of Contents

| Contents Page

|