|

Engineering News and American Railway Journal

— July 13, 1889

The Judson Pneumatic Railway System

With the multitude of patents already in existence for propelling

street-cars, it would be but natural to suppose that future inventors

had little left them other than some further improvement upon

methods in use. But in the street railway system about to be described

the direct motive power is independent of horses, steam, electricity,

compressed-air motors on the car or cables. It is, in fact, a

new departure, differing most essentially from all previous schemes

for producing similar results.

As will be better understood by examining the accompanying

illustrations, the Judson system is founded upon a new mechanical

movement, a new method of converting rotary into rectilinear motion.

It is a screw, but without a thread; and this screw

though always revolving in one direction, will send the cars in

either direction, and do this by a pure and simple rolling and

not a sliding friction. But to understand this novel and at first

puzzling mechanical movement, it is best to refer at once to the

cuts shown.

In Figs. 1 and 3 we have illustrated the controlling principle

of this invention. Instead of a cable a line of coupled steel

tubing (A), about 12 ins. in diameter, is run in a subway and

supported at intervals by pillow-blocks. At long intervals this

line of tubing is revolved at a constant speed by any power desirable,

whether water, steam, or electricity; though the introducers of

this system give several good reasons for preferring compressed

air above other motive powers. Successful practice in England

and France has demonstrated the fact that compressed air is one

of the best and most economical methods of transmitting power

from a central station to other stations for use at varying distances,

and its application is less liable than that of other powers to

introduce any element of danger or create a nuisance of any description

on the line of our public highways.

Coming back to the tube itself,

in Fig. 1 A represents a hollow cylinder with a perfectly

smooth surface rotating on its axis continuously in one direction

E E are friction wheels resting on opposite quarters of

the drum A and adjustable in the planes of their axes,

and like the drum having a perfectly smooth periphery. When in

contact with the moving drum amid in the position No. 1, these

wheels simply rotate without imparting any linear impulse. But

turn them slightly into the position shown in No. 2, and they

move forward on the path of a finely threaded screw, as shown

by the dotted lines, with adhesion between the surfaces taking

the place of the regular screw and nut. In No. 2 position, the

speed is slow, but tractive power is great, just the quality of

power best adapted to starting a car from a state of rest. When

the start is made, more speed is wanted, and the tractive power

can be safely reduced by gradually assuming the positions 3 and

4 in Fig. 1. This change in the position of the motor-wheels is

smooth and gradual and the application and economy of power is

self-evident to every mechanical engineer. Coming back to the tube itself,

in Fig. 1 A represents a hollow cylinder with a perfectly

smooth surface rotating on its axis continuously in one direction

E E are friction wheels resting on opposite quarters of

the drum A and adjustable in the planes of their axes,

and like the drum having a perfectly smooth periphery. When in

contact with the moving drum amid in the position No. 1, these

wheels simply rotate without imparting any linear impulse. But

turn them slightly into the position shown in No. 2, and they

move forward on the path of a finely threaded screw, as shown

by the dotted lines, with adhesion between the surfaces taking

the place of the regular screw and nut. In No. 2 position, the

speed is slow, but tractive power is great, just the quality of

power best adapted to starting a car from a state of rest. When

the start is made, more speed is wanted, and the tractive power

can be safely reduced by gradually assuming the positions 3 and

4 in Fig. 1. This change in the position of the motor-wheels is

smooth and gradual and the application and economy of power is

self-evident to every mechanical engineer.

The reverse of these movements, from No. 4 to No. 1, brings

the car gradually to a stand still again; or if the movement of

the friction wheels is continued until No. 2 stands in the direction

opposite to that shown in the cut, the motion of the car will

be reversed, and it will back with the same speed and power it

had in moving forward, and accomplish this with the drum A

still rotating in its former direction. Thus, with one simple

lever connected with these friction wheels, the operator can start,

stop reverse and vary at will the speed of the car.

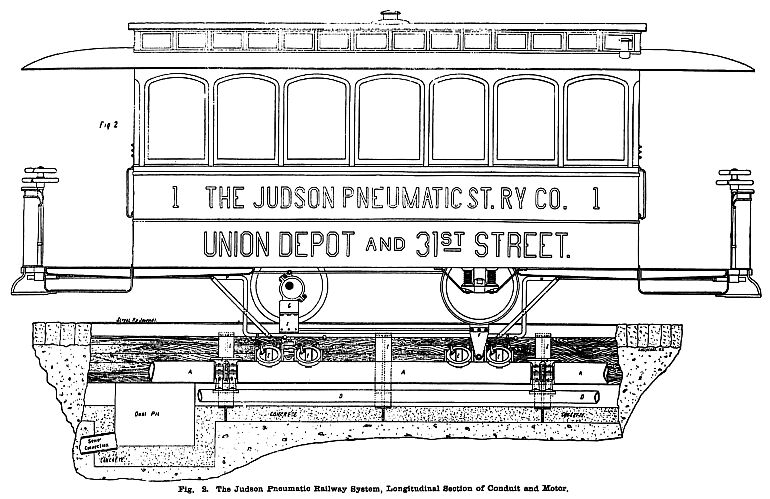

Fig. 2 shows a longitudinal section of the car-propelling mechanism

and the conduit. As it stands, the plane of the friction wheels

is at right angles to the axis of the drum, and the car is stopped.

On the front platform are two hand-wheels, superimposed. The wheel

J is rigidly fastened to a rod terminating in a cog-pinion

under the car platform, and this pinion is in mesh with two racks,

one on either side, which are rigidly connected with the lever

H. This last lever passes down into the conduit, and is

linked by ball-and-socket connections with the spiders which support

the friction wheels E E. By this connection, when the operator

slightly turns the hand-wheel J, all of the friction wheels

on one side of the drum are thrown to a certain angle and all

the wheels on the other side are thrown to exactly the same pitch

line in the opposite direction, and the car moves foward as previously

described.

The hand-wheel K, shown under J in Fig. 2, is

used as follows: As the minimum of pressure between the friction

wheels and the drum A is desirable, this pressure is normally

supposed to be just sufficient to maintain the desired speed on

a level track. A grade or a curve will of course present a greater

resistance and demand an increase in the tractive power to overcome

it. This increase is gained by taking hold of the wheel K,

which is fixed to a hollow shaft surrounding the stem of J,

and by a slight turn operating eccentrics which throw as much

of the weight of the car upon the friction wheels as is desired

to gain the required tractive force. By turning K in the

other direction, the friction wheels can be lifted entirely out

of contact with the drum A, and thus reduce the wear and

tear when standing still. Similar sets of wheels at both ends

of the car avoid any necessity for turning the car at the end

of the route. The wheels E E, in position No. 1, Fig. 1,

constitute in themselves a powerful brake.

In Fig. 2 A is the propelling drum; B is the

pillow-block in which the journals of A rest, completely

housed over to protect it from dust and dirt C is a "bridge

rail" to carry the friction wheels over the space left at

the journals; D is the tube conveying compressed-air; F

is the "slot-blade," or the connection between the traction

wheels and the car; G are "spring-boxes" contain-lug

coiled springs and connected with the axle of the car through

the eccentrics, with the purpose of relieving the friction wheels

from any sudden jar or pounding arising from unevenness of track,

etc.; and I is the cast-iron yoke, similar to those used

in cable construction, but lighter.

The depth from street surface to base of the concrete foundation

to the conduit is 3 ft., and the conduit proper is 2 ft. deep

by 22 ins. wide at the widest point. The bottom of the conduit

is smooth and shaped to form a gutter on each side of the drum.

A brush or scraper could easily be attached to the framework of

the friction wheels and so used as to gather up all dirt and deposit

it in pits (as shown in Fig. 2). The top of this conduit is also

removable (see Fig. 3), and can be lifted out in ten 12 ft. sections

so that repairs may be made without tearing up the street surface.

The small compressed-air engine to be used in rotating the

drum is shown in Fig. 4. In this illustration, M is a small

air pipe conducting the air from the main supply pipe D

into the heater L, where the compressed air is heated to

any desired degree before it is permitted to go into the engine

cylinders through the governor. N is a lever connected

with a clutch, and by it the engines are thrown into or out of

gear with the drum. It wall be observed that one set of these

cylinders drives the drum on both the going and the coming track,

so that one main supply pipe and one set of connections only is

required for each engine. These engines will be placed as shown,

beneath and between the two tracks, in a pit provided for them

and it is believed that they will be required not oftener than

once in 1,500 ft. on straight lines, and perhaps somewhat nearer

if many curves are encountered. They are very simple and inexpensive,

costing not more than $200 each.

In this connection we may say that every detail in regard to

curves, grades, switches or turnouts, crossings, etc., has been

worked out by the inventor until this system stands forth with

such completeness as to be at once a marvel to outsiders and a

tribute to the genius of the inventor. The system is peculiarly

adapted to elevated railroads and would relieve the structure

greatly and abate all nuisances. As the cars can be run in either

direction at the will of the operator, and switches or turn-outs

are easily provided, it is also applicable to single-track lines

in small or suburban cities where traffic will not warrant double

tracks. The offices of the Judson Pneumatic Street Railway Co.

are in rooms 143, 144, 145, Aldrich Court, 45 Broadway, New York

City, where further information concerning this new departure

can be obtained.

Stories Page

| Contents Page

|