|

THE PROSPECT MOUNTAIN CABLE INCLINE RAILWAY;

LAKE GEORGE, N. Y.

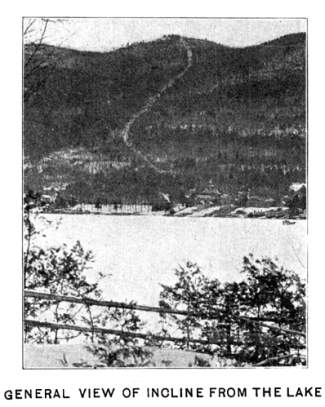

The latest

addition to inclined railways built in this country for the attraction

and accommodation of tourist traffic is the Prospect Mountain

Incline Railway at Lake George, which was built last winter for

the Horicon Improvement Co. The railway starts from a point near

the terminus of the Delaware & Hudson R. R. at Caldwell, N.

Y., and ascends Prospect Mountain, about 1½ miles west

of that place, rising in 6,625.7 ft. to an elevation of 1,950

ft. above Lake George and 2,250 ft. above sea level. From the

summit of the mountain there is a wide range of view, comprising

the southern peaks of the White Mountains in New Hampshire, the

Green Mountains in Vermont, the Catskill and Adirondack Mountains

in New York, and the Berkshire Hills in Massachusetts. Lake George

is the largest and most easterly of the lakes of the Adirondack

region. It is about 210 miles from New York and 71 miles from

Albany. The lake is 346 ft. above sea level and 247 ft. above

Lake Champlain. The region is a famous summer resort, and is rich

in historical associations; the ruins of Fort George, Fort William

Henry and Fort Ticonderoga serving as reminder, of the early days

when numerous battles were fought here between the French and

English armies and the Indians. The names of Generals Abercrombie,

Howe and Burgoyne, of the English armies, and General Montcalm,

of the French army, are associated with the military history of

the region. The latest

addition to inclined railways built in this country for the attraction

and accommodation of tourist traffic is the Prospect Mountain

Incline Railway at Lake George, which was built last winter for

the Horicon Improvement Co. The railway starts from a point near

the terminus of the Delaware & Hudson R. R. at Caldwell, N.

Y., and ascends Prospect Mountain, about 1½ miles west

of that place, rising in 6,625.7 ft. to an elevation of 1,950

ft. above Lake George and 2,250 ft. above sea level. From the

summit of the mountain there is a wide range of view, comprising

the southern peaks of the White Mountains in New Hampshire, the

Green Mountains in Vermont, the Catskill and Adirondack Mountains

in New York, and the Berkshire Hills in Massachusetts. Lake George

is the largest and most easterly of the lakes of the Adirondack

region. It is about 210 miles from New York and 71 miles from

Albany. The lake is 346 ft. above sea level and 247 ft. above

Lake Champlain. The region is a famous summer resort, and is rich

in historical associations; the ruins of Fort George, Fort William

Henry and Fort Ticonderoga serving as reminder, of the early days

when numerous battles were fought here between the French and

English armies and the Indians. The names of Generals Abercrombie,

Howe and Burgoyne, of the English armies, and General Montcalm,

of the French army, are associated with the military history of

the region.

The old Lake House, at the summit of Prospect Mountain, was

bought last year by Mr. Wm. M. Peck, of Glens Falls, N. Y., who

has made considerable improvements and extensions, and the railway

and hotel are owned by the Horicon Improvement Co., of which Mr.

Peck is President and Mr. A. B. Colvin, of Albany, N. Y., State

Treasurer, is a director. Construction of the railway was commenced

on Jan. 2, 1895, and was carried on through many difficulties

incident to the cold and snow. The first car was run on June 2

and the road was opened to traffic on June 15. The total cost

was about $120,000.

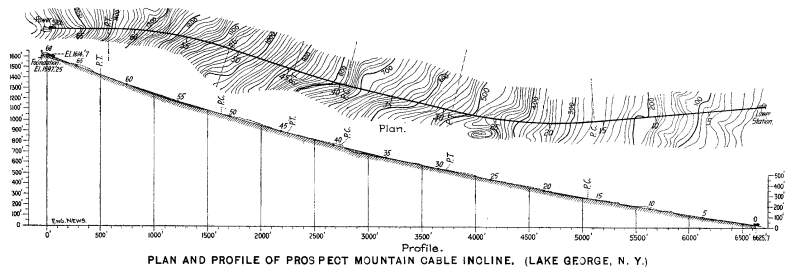

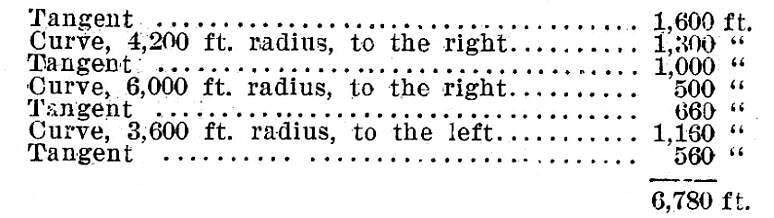

The length of the line, measured on a level, is 6,625.7 ft., and

the total rise is 1,594.7 ft., the length measured on the grade

of the incline being 6,780 ft. The average grade is 24%, the maximum

grade being 37.8% and the minimum 13½%. The alinement,

commencing at the lower station and not including the turnout

curves at the middle, is about as follows:

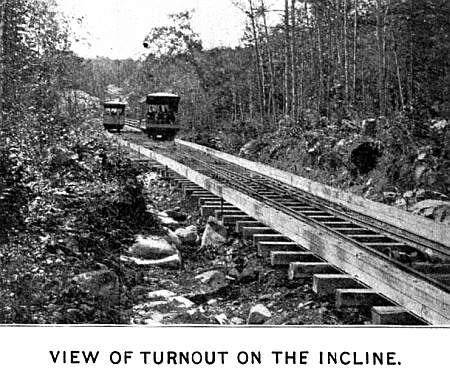

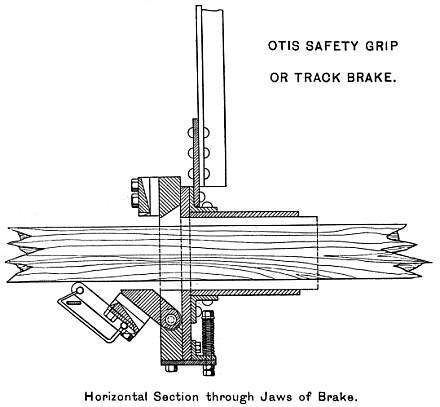

The line has a

single track of 3-ft. gage, with a four-rail turnout on passing

place at the middle. The rails weigh 35 lbs. per yd., and are

spiked to ties 6 x 6 ins. and 8 ft. long, spaced about 24 ins.

c. to c. The joints are supported, spliced by plain fishplates,

and the ends of the rail base are notched for spikes to prevent

creeping. On each side of the track is a yellow pine guard rail,

6 x 8 ins., built up of two timbers 6 x 4 ins., laid to break-joints

and bolted with mushroom headed bolts at each tic. These guard

timbers are embraced by the Otis double-grip safety brake, which

is applied automatically in case of the car getting beyond control,

or can be applied by hand in case of emergency. The ties rest

upon longitudinal timbers, 6 x 10 ins., which are bolted to mudsills

spaced 6 ft. 8 ins. apart, or 4 ft. apart under the joints of

the stringers. The line is in cut and fill, with the exception

of four trestles. On the lower half of the line the excavation

is mainly in earth and hardpan, while on the upper part the excavation

is in granite. The four trestles aggregate 1,400 ft. in length,

and have a maximum height of about 25 ft. They are built of native

hemlock, except that the stringers are of Southern yellow pine,

and the construction closely resembles that used on the Catskill

Mountain cable incline, shown in our issue of Aug. 18, 1892. The

bents are 16 ft. apart, and are built up of two plumb-posts 10

x 10 ins. and two batter-posts 8 x 10 ins., formed into sills

10 x 10 ins., and caps 10 x 10 ins. x 8 ft. The transverse diagonal

bracing is of planks, 2½ x 8 ins., spiked to the caps and

sills, and longitudinal diagonal bracing is placed between some

of the bents. There are also longitudinal timbers, 4 x 8 ins.,

bolted to the inside of the bottom of the plumb-posts. Under each

rail are two stringers 6 x 14 ins. on edge, laid to break-joint,

and separated by 2-in. thimbles, and these stringers rest on corbels

6 x 12 ins., 3 ft. long, notched onto the caps, to give the proper

inclination for the stringer bearings. The ties are 6 x 6 ins.,

18 ins. apart in the clear. They are 13 ft. long, carrying a 42-in.

footway on one side, protected by a wooden railing 4 ft. high. The line has a

single track of 3-ft. gage, with a four-rail turnout on passing

place at the middle. The rails weigh 35 lbs. per yd., and are

spiked to ties 6 x 6 ins. and 8 ft. long, spaced about 24 ins.

c. to c. The joints are supported, spliced by plain fishplates,

and the ends of the rail base are notched for spikes to prevent

creeping. On each side of the track is a yellow pine guard rail,

6 x 8 ins., built up of two timbers 6 x 4 ins., laid to break-joints

and bolted with mushroom headed bolts at each tic. These guard

timbers are embraced by the Otis double-grip safety brake, which

is applied automatically in case of the car getting beyond control,

or can be applied by hand in case of emergency. The ties rest

upon longitudinal timbers, 6 x 10 ins., which are bolted to mudsills

spaced 6 ft. 8 ins. apart, or 4 ft. apart under the joints of

the stringers. The line is in cut and fill, with the exception

of four trestles. On the lower half of the line the excavation

is mainly in earth and hardpan, while on the upper part the excavation

is in granite. The four trestles aggregate 1,400 ft. in length,

and have a maximum height of about 25 ft. They are built of native

hemlock, except that the stringers are of Southern yellow pine,

and the construction closely resembles that used on the Catskill

Mountain cable incline, shown in our issue of Aug. 18, 1892. The

bents are 16 ft. apart, and are built up of two plumb-posts 10

x 10 ins. and two batter-posts 8 x 10 ins., formed into sills

10 x 10 ins., and caps 10 x 10 ins. x 8 ft. The transverse diagonal

bracing is of planks, 2½ x 8 ins., spiked to the caps and

sills, and longitudinal diagonal bracing is placed between some

of the bents. There are also longitudinal timbers, 4 x 8 ins.,

bolted to the inside of the bottom of the plumb-posts. Under each

rail are two stringers 6 x 14 ins. on edge, laid to break-joint,

and separated by 2-in. thimbles, and these stringers rest on corbels

6 x 12 ins., 3 ft. long, notched onto the caps, to give the proper

inclination for the stringer bearings. The ties are 6 x 6 ins.,

18 ins. apart in the clear. They are 13 ft. long, carrying a 42-in.

footway on one side, protected by a wooden railing 4 ft. high.

The work was laid

out entirely by measurements parallel to the grade line, so that

the difference of elevation at any two stations is the sine of

the angle of the slope at that point, the horizontal distance

being the cosine. The contours on the topographical plan accompanying

the profile represent, therefore, not a vertical projection, as

in ordinary practice, but a development of the topography by rolling

out on the grade line. This method is said to, have greatly facilitated

the calculations of grade and power required. The grades are so

adjusted that the two trains with average loads, and including

the weight of the cable, balance each other at all points of line.

The curvature of the grade is not continuously convex downward,

but is flattened for a short distance near the turnout by means

of a curve convex upward, making a slight reverse curve in the

profile. The calculations for balancing grades were made for cars

weighing 14,000 lbs., carrying 27 passengers at 150 lbs. each

(or 18,050 lbs. at each end of the cable), and a cable weighing

2½ lbs. per ft. The work was laid

out entirely by measurements parallel to the grade line, so that

the difference of elevation at any two stations is the sine of

the angle of the slope at that point, the horizontal distance

being the cosine. The contours on the topographical plan accompanying

the profile represent, therefore, not a vertical projection, as

in ordinary practice, but a development of the topography by rolling

out on the grade line. This method is said to, have greatly facilitated

the calculations of grade and power required. The grades are so

adjusted that the two trains with average loads, and including

the weight of the cable, balance each other at all points of line.

The curvature of the grade is not continuously convex downward,

but is flattened for a short distance near the turnout by means

of a curve convex upward, making a slight reverse curve in the

profile. The calculations for balancing grades were made for cars

weighing 14,000 lbs., carrying 27 passengers at 150 lbs. each

(or 18,050 lbs. at each end of the cable), and a cable weighing

2½ lbs. per ft.

The cable is 1¼ ins. diameter, weighing 2.528 lbs. per

ft., and is 7,150 ft. long, making four wraps on the winding drums.

The ends of the cable are attached to the downhill side of the

car frames, the cable passing under a saddle at the front of the

car, which holds it down to within a few inches of the idler pulleys.

These pulleys are of cast iron, 12 ins. diameter (to center of

cable) on the tangents and 15 ins. on the curves, the latter being

inclined towards the center of the curve and having a very high

flange on the outer side. The pulleys are set 30 ft. apart, those

for the ascending and descending cable being set two tie spaces

apart, in order to provide room for the boxes and bearings. The

pulley bearings run in babbitted boxes, and these boxes are supported

by wrought iron straps bent to shape and fastened to the ties

by lag screws. At the turnout the cable, which is normally above

the rails, passes through a slot in the rails, dropping into the

slot by its own weight and being guided by special pulleys for

this purpose The turnout is operated automatically.

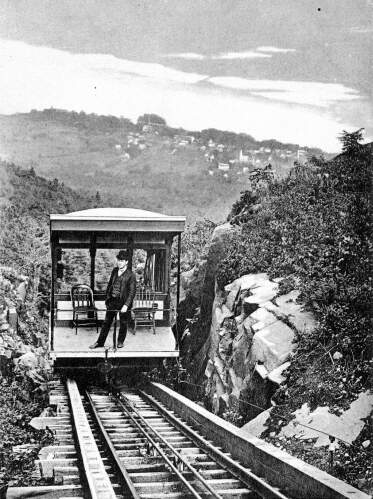

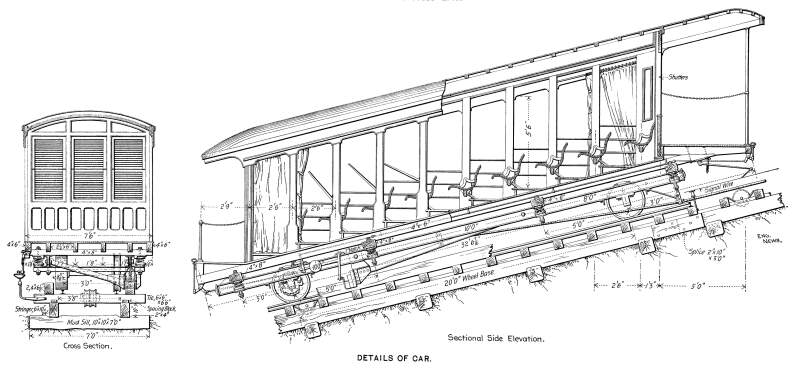

The cars are open, with canvas side curtains for use in bad

weather, and have nine transverse seats; the seats being so set

as to be horizontal on the grade. Each car is about 32 ft. long

and 7 ft. 6 ins. wide, weighs a little over 13,000 lbs., and has

seating accommodations for 54 passengers while 80 or 90 persons

can be accommodated by standing. The front platform is of extra

length, and is intended to carry freight and baggage. The car

frame is of channel iron, and each car is carried on four 24-In.

wheels, the wheelbase being 20 ft. The wheels on one side (on

the outer rail) are double-flanged, or grooved, while those on

the other side are

flat, 8 ins. wide, in order to pass over the turnout, the flat

wheel passing over the slot through which the cable drops, as

above described. There is telephone communication between the

cars and the power house, a copper signal wire being supported

on iron standards attached to the ends of the ties, as shown,

each car having a wire loop contact piece attached to the end

of a vertical rod and held down upon the line wire by a spring.

This wire contact replaces a grooved contact wheel, which was

found to be liable to jump off the wire. Each car is also fitted

with the necessary equipment of batteries, telephone and signal

bell, and there is a code of bell signals for starting and stopping.

The running speed is 850 ft. per minute, or about 10 miles per

hour and the trip occupies about eight minutes on the average. the other side are

flat, 8 ins. wide, in order to pass over the turnout, the flat

wheel passing over the slot through which the cable drops, as

above described. There is telephone communication between the

cars and the power house, a copper signal wire being supported

on iron standards attached to the ends of the ties, as shown,

each car having a wire loop contact piece attached to the end

of a vertical rod and held down upon the line wire by a spring.

This wire contact replaces a grooved contact wheel, which was

found to be liable to jump off the wire. Each car is also fitted

with the necessary equipment of batteries, telephone and signal

bell, and there is a code of bell signals for starting and stopping.

The running speed is 850 ft. per minute, or about 10 miles per

hour and the trip occupies about eight minutes on the average.

The safety grip consists of a heavy steel plate embracing the

guard timber and resting against a butting frame of plates and

angles, forming part of the car frame. A hinged dog is attached

to the grip plate, and lies on the inner side of the guard timber.

Both plate and dog have chiseled edges and are fitted with toothed

plates. The hinged dog is held away from contact with the guard

timber by a weighted lever having a vertical leg, whose end rests

in the notch of a latch carried by a shaft, which is fitted with

a pawl opposite the speed governor of the car axle. The main grip

plate is held away from contact with the guard timber by a brass

spring. The governor itself is similar in operation to the ball

governor of a steam engine, but the balls are replaced with heavy

plates, or jaws, having lugs or teeth formed on the outer edges.

When the car attains excessive speed in descending, the plates

fly out far enough to bring the teeth in contact with the pawl,

thus releasing the latch and causing the weighted lever to drop,

forcing the toothed dog and grip into the guard timber to a depth

of about three-eigths in. on each side. The resisting power of

this safety grip, acting on a yellow pine guard rail, has been

found by experiment to be 28,000 lbs. The governor is set to act

at a speed of 14 miles per hour. To release the grip, the motion

of the car is reversed, so as to relieve the strain on the grip,

and the conductor then pulls up the lever and sets it in the latch,

after which the car can go ahead again. As the car must be drawn

back before the grip can be released, it is evident that the conductor

cannot release it unless the cable is intact. If from any cause

the car should get beyond control, the conductor can apply the

safety grip, throwing the latch by means of the handle shown in

front of the dashboard, without waiting for the car to attain

sufficient speed to cause the governor to apply the brake.

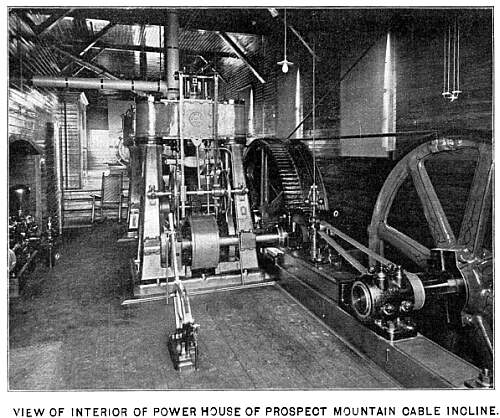

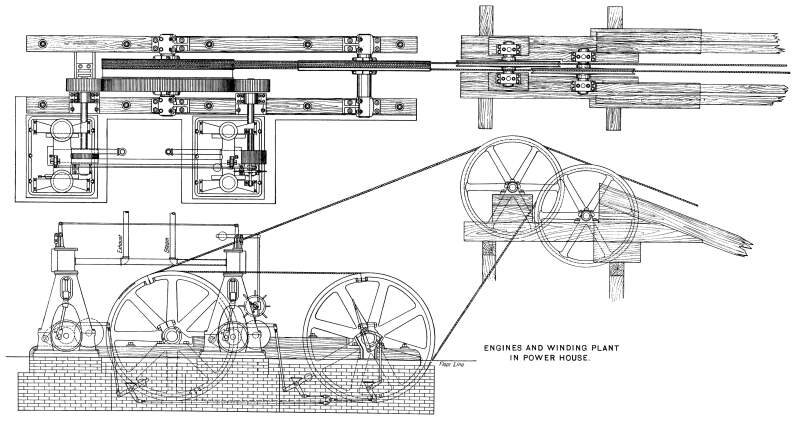

The hoisting plant

is contained in a power house at the upper end of the incline.

It consists of two Otis vertical inverted compound engines of

the marine type, with cylinders 8 x 10 and 12 x 10 ins., and running

at about 200 revolutions per minute. The exhaust of one engine

is used in the low-pressure cylinder of the other, and valves

are arranged in the steam pipes so that both engines can take

live steam direct from the boilers in case of extra heavy loads,

but this has not been necessary so far, as the engines are found

to be capable of doing all the work required when working as compounds.

They develop about 90 HP. when working compound, and can develop

up to 200 HP. when working simple. Each engine drives a pinion

23 ins. diameter, the pinions being on opposite sides of the main

spur wheel, which has a diameter of 8 ft. on the pitch line, a

face 9 ins. wide, and teeth set at a pitch of about 2½

ins. The shaft of this wheel drives two cast iron drums 8 ft.

diameter, one being an idler and the other a driving wheel, and

the cable makes four turns round these drums. The engines are

provided with a hand brake, and also with an emergency brake acting

on the main driving drum, but there has been no necessity for

the use of either of these brakes as yet, the working being completely

controlled by the use of the steam valves. Steam is supplied by

a Heine water-tube boiler of 200 HP., built by the Heine Safety

Water Tube Boiler Co., of St. Louis, Mo., and this boiler also

supplies steam for the electric plant for lighting the stations

and hotels connected with the plant. The current is generated

by a Westinghouse alternating dynamo, with a capacity for 1,100

lights of 16 c. p. There are converters at top and bottom of the

incline. The water is taken from a mountain brook and pumped up

into tanks of 12,000 gallons capacity at the power house by a

special boiler and pump placed in the Valley to the west of the

summit, at a point about 4,000 ft. distant from, and 600 ft. below,

the summit. The supply of water is also used for the hotels and

other buildings. The hoisting plant

is contained in a power house at the upper end of the incline.

It consists of two Otis vertical inverted compound engines of

the marine type, with cylinders 8 x 10 and 12 x 10 ins., and running

at about 200 revolutions per minute. The exhaust of one engine

is used in the low-pressure cylinder of the other, and valves

are arranged in the steam pipes so that both engines can take

live steam direct from the boilers in case of extra heavy loads,

but this has not been necessary so far, as the engines are found

to be capable of doing all the work required when working as compounds.

They develop about 90 HP. when working compound, and can develop

up to 200 HP. when working simple. Each engine drives a pinion

23 ins. diameter, the pinions being on opposite sides of the main

spur wheel, which has a diameter of 8 ft. on the pitch line, a

face 9 ins. wide, and teeth set at a pitch of about 2½

ins. The shaft of this wheel drives two cast iron drums 8 ft.

diameter, one being an idler and the other a driving wheel, and

the cable makes four turns round these drums. The engines are

provided with a hand brake, and also with an emergency brake acting

on the main driving drum, but there has been no necessity for

the use of either of these brakes as yet, the working being completely

controlled by the use of the steam valves. Steam is supplied by

a Heine water-tube boiler of 200 HP., built by the Heine Safety

Water Tube Boiler Co., of St. Louis, Mo., and this boiler also

supplies steam for the electric plant for lighting the stations

and hotels connected with the plant. The current is generated

by a Westinghouse alternating dynamo, with a capacity for 1,100

lights of 16 c. p. There are converters at top and bottom of the

incline. The water is taken from a mountain brook and pumped up

into tanks of 12,000 gallons capacity at the power house by a

special boiler and pump placed in the Valley to the west of the

summit, at a point about 4,000 ft. distant from, and 600 ft. below,

the summit. The supply of water is also used for the hotels and

other buildings.

The road was designed and built for the Horicon Improvement Co.,

by the Otis Engineering & Construction Co., of New York city,

and the operating plant was designed by Mr. Thomas E. Brown, Jr.,

M. Am. Soc. C. E., Chief Engineer and Manager of the latter company,

to whom we are indebted for drawings and particulars used in preparing

this article. Mr. C. F. Parker was the Resident Engineer. The

grading trestles and trackwork were sublet to Mairs & Lewis,

of New York city. The engines, safety devices, etc., were furnished

by Otis Brothers & Co., of New York city, and the winding

drums, pulleys, cars and frog and switch equipment by the Ramapo

Iron Works, of Hillburn, N. Y. The cable, which is of the Lang-Lay

pattern, was made by the John A. Roebling's Sons Co., of Trenton,

N. J. The electric lighting plant was furnished by Westinghouse,

Church, Kerr & Co., of New York city.

Stories Page | Contents Page

|