|

The Railways of America—1890

THE most notable invention of latter days in bridge construction

is that of the cantilever bridge, which is a system devised to

dispense with staging, or false works, where from the great depth,

or the swift current, of the river, this would be difficult, or,

as in the case of the Niagara River, impossible to make. The word

cantilever is used in architecture to signify the lower end of

a rafter, which projects beyond the wall of a building, and supports

the roof above. It is from an Italian word, taken from the Latin

cantilabrum (used by Vitruvius), meaning the 1ip of

the rafter. If two beams were pushed out from the shores of

a stream until they met in the centre, and these two beams were

long enough to run back from the shores until their weight, aided

by a few stones, held them down, we should have a primitive form

of the cantilever, but one which in principle would not differ

from the actual cantilever bridges. This is another American invention,

although it has been developed by British engineers-Messrs. Fowler

& Baker-in their huge bridge now building across the Forth,

in Scotland, of a size which dwarfs everything hitherto done in

this country, the Brooklyn bridge not excepted.

The first design of which we have any record was that of a

bridge planned by Thomas Pope, a ship carpenter of New York, who,

in 1810, published a book giving his designs for an arched bridge

of timber across the North River at. Castle Point, of 2,400 feet

span. Mr. Pope called this an arch, but his description clearly

shows it to have been what we now call a cantilever. As was the

fashion of the day, he indulged in a poetical description:

"Like half a Rainbow rising on yon shore,

While its twin partner spans the semi o'er,

And makes a perfect whole that need not part

Till time has furnish'd us a nobler art."

The first railway cantilever

bridge in the world was built by the late C. Shaler Smith, C.E.,

one of our most accomplished bridge engineers. This was a bridge

over the deep gorge of the Kentucky River. The next was a bridge

on the Canadian Pacific, in British Columbia, designed by C. C.

Schneider, C.E. A very similar bridge is that over the Niagara

River, designed by the same engineer in conjunction with Messrs.

Field & Hayes, Civil Engineers. This bridge was the first

to receive the distinctive name of cantilever. The first railway cantilever

bridge in the world was built by the late C. Shaler Smith, C.E.,

one of our most accomplished bridge engineers. This was a bridge

over the deep gorge of the Kentucky River. The next was a bridge

on the Canadian Pacific, in British Columbia, designed by C. C.

Schneider, C.E. A very similar bridge is that over the Niagara

River, designed by the same engineer in conjunction with Messrs.

Field & Hayes, Civil Engineers. This bridge was the first

to receive the distinctive name of cantilever.

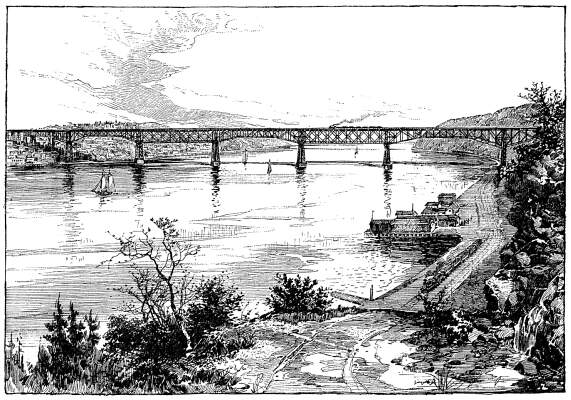

The new bridge at Poughkeepsie has three of these cantilevers,

connected by, two fixed spans, as shown in the illustration. The

fixed spans have horizontal lower chords, and really extend beyond

each pier and up the inclined portions, to where the bottom

chord of the cantilever is horizontal. At these points the

junctions between the spans are made, and arranged in such a way,

by means of movable links, that expansion and contraction due

to changes of temperature can take place. The fixed spans are

525 feet long. Their upper chord, where the tracks are placed,

is 212 feet above water. These spans required stagings to build

them upon. These stagings were 220 feet above water, and rested

on piles, driven through 60 feet of water and 60 feet of mud,

making the whole height of the temporary staging 332 feet, or

within 30 feet of the height of Trinity Church steeple, in New

York. The time occupied in building one of these stagings and

then erecting the steel-work upon it was about four months.

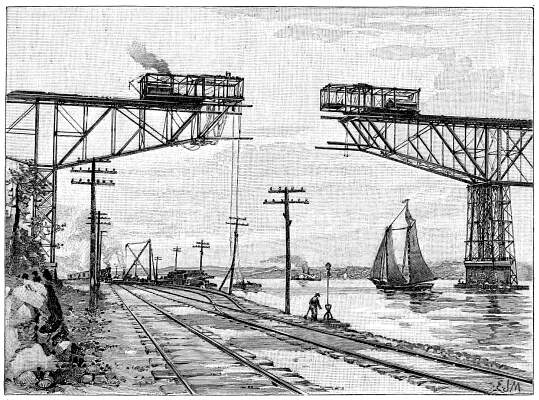

The cantilever spans were erected,

as shown in the illustration, without any stagings at all below,

and entirely from the two overhead travelling scaffolds, shown

in the engraving. These scaffolds were moved out daily from the

place of beginning over the piers, until they met in the centre.

The workmen hoisted up the different pieces of steel from a barge

in the river below and put them into place, using suspended planks

to walk upon. The time saved by this method was so great that

one of these spans of 548 feet long was erected in less than four

weeks, or one-seventh of the time which would have been required

if stagings had been used. The cantilever spans were erected,

as shown in the illustration, without any stagings at all below,

and entirely from the two overhead travelling scaffolds, shown

in the engraving. These scaffolds were moved out daily from the

place of beginning over the piers, until they met in the centre.

The workmen hoisted up the different pieces of steel from a barge

in the river below and put them into place, using suspended planks

to walk upon. The time saved by this method was so great that

one of these spans of 548 feet long was erected in less than four

weeks, or one-seventh of the time which would have been required

if stagings had been used.

At the Forth Bridge, all the projecting cantilevers will be

built from overhead scaffolds, 360 feet above the water. It contains

two spans of 1,710 feet each. When spans of this length are used,

the rivets become very long—seven inches—and it would

be impossible to make a good job by hand riveting. Hence a power-riveter

is used in riveting the work upon the staging. A steam engine

raises up a heavy mass of cast-iron, called "the accumulator;"

the weight of this in descending is transmitted through tubes

of water, and its power increased by contracting the area of pressure,

until some twenty tons can be applied to the head of each rivet.

One rivet per minute can be put in with this tool.

It will be seen that most of the great saving of time in modern

construction of bridges and other parts of railways is due to

improved machinery. The engineer of to-day is probably not more

skillful than his ancestor, who, in periwig and cue, breeches

and silk stockings, is represented in old prints supervising a

gang of laborers, who slowly lift the ram of a pile-driver by

hauling on one end of a rope passed over a pulley-wheel. The modern

engineer has that useful servant, steam, and the history of modern

engineering is chiefly the history of those inventions by which

steam has been able to supersede manual labor—such as pile-drivers,

steam-shovels, steam-dredges, and other similar tools.

Poughkeepsie Bridge | Bridge

Page | Contents Page

|