A Text Book on Civil Engineering

Copyright 1897, 1898, 1899 by The Colliery Engineer Company

WATER STATIONS.

1815. Water stations are points along a railroad where

the engines stop to take in water. Their distance apart will depend

mainly upon the amount of the traffic, but somewhat upon the grades.

On roads with a light traffic, water stations at intervals of

15 miles will meet every requirement, while roads with a heavy

traffic and frequent trains may require them at every 5 or 6 miles.

They usually consist of large wooden tubs placed upon a strong

framework, supported by heavy pillars which rest upon a foundation

of masonry. The tubs are generally circular in form, the bottom

diameter being a few inches larger than that of the top diameter,

in order that the iron hoops may drive tight. White pine, cedar,

and redwood are the varieties of timber principally used in the

manufacture of tanks. The staves are planed by machinery specially

designed to give them the proper bevel, so that when set up the

joints are close and water-tight. The staves are fastened together

at the top with a single dowel between each two, merely to hold

them in place while being, set up. The pieces forming the bottom

of the tank are doweled together and fit into a groove about I

inch in depth, which is cut into the staves to receive them. The

hoops are fastened together with lugs which grip the two ends

of the hoop. The two lugs are united by a bolt threaded at both

ends and fitted with nuts. By screwing up these nuts, a strain

is put upon the hoop. The hoops are first nearly driven to place;

the lugs are then tightened with a wrench, after which the driving

is finished.

Railroad water tanks hold from 20,000 to 40,000 gallons. A

common size is 16 ft. in diameter and 16 ft. in height, holding

about 21,000 gallons. All tanks holding above 200 barrels are

made from 3-in. stuff. This thickness is some what reduced by

planing. The bottom of the tank should be from 10 to 12 ft. above

the tops of the rails. It is a common practice to enclose the

tank in a framed structure, the foundation and post supports forming

the first story, and the tank, together with its covering, the

second story. Where the supply of water is pumped, the first story

is often used as a pump house, and a fire is usually maintained

in winter to prevent the freezing of the water. At division or

terminal points, where many engines are to be supplied, the tank

is made proportionately larger, and often two are placed together.

It is desirable to combine a coaling with a water station,

in order that an engine may take both fuel and water at the same

time. Such an arrangement is usually made at division points and

terminals, though it is not always practicable to place a water

tank and coaling station side by side.

A tender of coal will serve for several tankfuls of water,

so that coaling stations situated at division points, at intervals

of say 100 miles, will serve every requirement.

When the railroad has a double track, it is customary to place

a water tank on each side of the roadway, so that engines may

take water from either track.

The tank house should stand near the track, leaving only from

2 to 4 feet clearance for cars.

1816. Source of Water Supply.—The least expensive

and most satisfactory water supply is that obtained from either

springs or brooks which have sufficient elevation to deliver water

into the tank by gravity and so avoid the expense of pumping.

Clear, pure water, as free as possible from mineral matter in

solution, is greatly to be desired. If the stream from which the

supply is obtained is liable to become muddy from freshets, a

reservoir of suitable size should be constructed and kept constantly

full of clear water, so that, in case of a freshet, the flow of

the water into the reservoir may be stopped until the stream runs

clear.

Where spring water is used, and the supply in times of drought

is liable to run short, a reservoir of ample capacity should be

constructed, and the surplus water stored for future use.

When the source of supply is too low to be delivered by force

of gravity, resort is had to pumping. Formerly, horsepower was

used to a considerable extent for pumping, but of late years steam

and wind power have been exclusively employed. Pumping by wind

mills is the least expensive, and, but for occasional calms, the

most satisfactory. The only way to provide against a short supply

due to calms is to make the capacity of the water tanks adequate

for a number of days' supply. The tank has three pipes: an inlet

pipe by which the water enters the tank, a waste pipe for preventing

overflow, and a discharge, or feed-pipe, 7 or 8 inches in diameter,

in or near the bottom, through which the water flows to the tender

tank. The discharge pipe is from 8 to 10 feet long, and jointed

at the end which joins the tank, so that when the tender tank

is filled, the discharge pipe, acted upon by a counterweight,

swings either sideways or vertically on its hinge joint, out of

reach of the cars. The discharge pipe at its connection with the

tank is provided with a valve which has a lifting gate. Movement

is communicated to this gate by means of a lever, the short arm

of which is attached to the valve rod. The long arm of the lever

has a rope attached, which hangs within reach of the engineman.

When taking water, the discharge pipe is lowered and swung

over the water hole in the tender tank. The engineman then pulls

down on the lever. This action raises the valve stem and allows

the water to flow from the water tank into the tender tank. Tender

tanks hold from 2,500 to 3,500 gallons.

1817. Standard Water Tanks.—A general plan of a

standard water tank is given in Fig. 632. The foundation is shown in

plan at A; a plan of the arrangement of timbers composing

the tank seat or deck is shown at B, and a complete elevation

of the tank at C. The foundations should be of the most

substantial character, of well-dressed stone laid in cement mortar.

The foundation consists of either continuous walls laid at right

angles; upon which the sills are placed and the posts mortised

into them, or a pediment of pyramidal form is built for each post,

as shown in the figure. Each post is secured to its pediment by

a dowel 1 in. in diameter by 6 in. in length. The stone pediment

forms a very substantial foundation. It is effective in appearance

and does away with the sills, which are apt to decay from alternate

wetting and drying.

The posts are connected together

by girts a, b, c, which are tenoned into the posts and

fastened with tree-nails. This connection is further strengthened

by 4 in. tie-rods d, e, f, which pass through each row

of posts, a cast washer being placed under the head and nut of

each tie-rod. Between each two rows of girts a series of X braces g, h, k is placed and

securely spiked to the posts and girts. The caps 1, m, n, o,

upon which the beams which compose the deck rest, are 12 in. x

12 in., and fastened to the posts by mortise and tenon. The deck

is composed of two sets of timbers laid at right angles to each

other. The first set, laid directly upon the posts, are 3 in.

x 12 in., and uniformly spaced. They are held together and strengthened

by bridging (see detail D) besides being spiked to the

caps. The second set of deck timbers are 4 in. x 6 in., and laid

at right angles to the floor-beams. They are spaced 19 in. center

to center, and extend to within 3 in. of the tank staves. They

are in direct contact with the bottom of the tank, and receive

the entire weight of the water contained in the tank without allowing

any of its weight to rest upon the staves. The deck is usually

made octagonal in form, and where the tank is not covered by a

house, the deck is made to project far enough from the tank (as

shown at E) to protect the foundation and timber supports

from the weather. The sides of the tank flare or batter outwards

at the rate of ½ in. to the foot, so that the hoops will

drive tight. The posts are connected together

by girts a, b, c, which are tenoned into the posts and

fastened with tree-nails. This connection is further strengthened

by 4 in. tie-rods d, e, f, which pass through each row

of posts, a cast washer being placed under the head and nut of

each tie-rod. Between each two rows of girts a series of X braces g, h, k is placed and

securely spiked to the posts and girts. The caps 1, m, n, o,

upon which the beams which compose the deck rest, are 12 in. x

12 in., and fastened to the posts by mortise and tenon. The deck

is composed of two sets of timbers laid at right angles to each

other. The first set, laid directly upon the posts, are 3 in.

x 12 in., and uniformly spaced. They are held together and strengthened

by bridging (see detail D) besides being spiked to the

caps. The second set of deck timbers are 4 in. x 6 in., and laid

at right angles to the floor-beams. They are spaced 19 in. center

to center, and extend to within 3 in. of the tank staves. They

are in direct contact with the bottom of the tank, and receive

the entire weight of the water contained in the tank without allowing

any of its weight to rest upon the staves. The deck is usually

made octagonal in form, and where the tank is not covered by a

house, the deck is made to project far enough from the tank (as

shown at E) to protect the foundation and timber supports

from the weather. The sides of the tank flare or batter outwards

at the rate of ½ in. to the foot, so that the hoops will

drive tight.

The discharge pipe p, when not in use, takes the position

shown in the figure, being held in that position by the weighted

ball g, which is attached to the chain r, running

through the sheaves s, and thence to its connection with

the discharge pipe. A cross-section of the track is shown at G,

the top of the rail being 12 ft. below the outlet of the discharge

pipe.

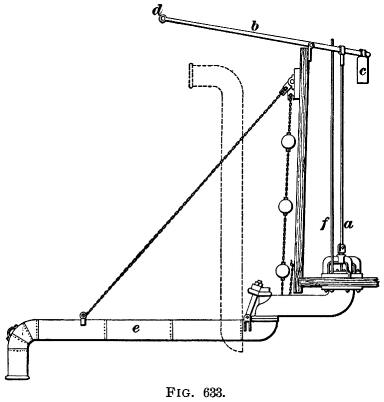

The valve connection of the discharge

pipe with the tank is shown in Fig. 633. The connection may be

made either through the side or bottom of the tank. The bottom

valve connection is shown in the figure. The valve rod a is attached

to the short arm of the lever b. The weight c, attached

to the end of the short arm of the lever, holds the valve firmly

in place. A rope is attached to the end d of the long arm

of the lever and hangs within reach of the engineman. By pulling

down on this rope, the valve is raised, and the water flows through

the discharge pipe a to the tender tank. The vacuum pipe f admits

air to the discharge pipe after the valve comes to its seat, so

that the discharge pipe is quickly voided. The valve connection of the discharge

pipe with the tank is shown in Fig. 633. The connection may be

made either through the side or bottom of the tank. The bottom

valve connection is shown in the figure. The valve rod a is attached

to the short arm of the lever b. The weight c, attached

to the end of the short arm of the lever, holds the valve firmly

in place. A rope is attached to the end d of the long arm

of the lever and hangs within reach of the engineman. By pulling

down on this rope, the valve is raised, and the water flows through

the discharge pipe a to the tender tank. The vacuum pipe f admits

air to the discharge pipe after the valve comes to its seat, so

that the discharge pipe is quickly voided.

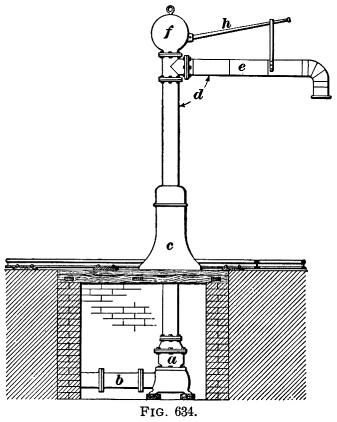

1818. Water Columns.—Where space is limited and

the head of water is sufficient, a water column (see Fig. 634)

is used in place of a tank. One advantage of a water column is

in its economy of space, as will be at once apparent. It can safely

be placed between the parallel tracks of a double-track road,

and serve engines on both tracks equally well.

This water column consists of a globe valve a, connecting

with the main water pipe b, and enclosed in a chamber of

brick masonry. This chamber is covered with a substantial floor

of timber, and forms the foundation for the pedestal c,

which supports the crane-shaped water column d. This column

is jointed at its connection with the pedestal, so that the discharge

pipe may be readily swung over the tender when taking water. The

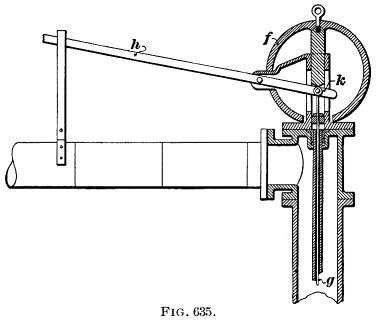

cast-iron globe f (Fig. 635) is connected with the valve

disk by means  of the valve rod

g, and by its weight keeps the valve closed. When taking

water, the lever h is depressed. This causes the short

arm k of the lever to rise, and lifts the globe f.

The weight being thus removed from the valve, the disk is lifted

by the pressure of the water which flows through the discharge

pipe to the tender tank. of the valve rod

g, and by its weight keeps the valve closed. When taking

water, the lever h is depressed. This causes the short

arm k of the lever to rise, and lifts the globe f.

The weight being thus removed from the valve, the disk is lifted

by the pressure of the water which flows through the discharge

pipe to the tender tank.

Structures | Contents

Page

|