|

1087

CURVED TRACK.

1664. Difference in Length of Inner and Outer Rails of a

Curve.—It is evident that the radius of the outer

rail of a curve is greater than that of the inner rail, and, consequently,

its length is greater. This difference may be taken at 1 and one-thirty-second

inches per degree of curve per 100 feet, for standard gauge track.

The difference in length between the inner and the outer rails

of a curve may be found by any of the three following rules:

Rule 1.—Multiply the degree of the curve by

the length in stations of 100 feet, and this product by 1and one-thiryty-second

inches. The result will be the difference in length between the

inner and outer rails in inches.

EXAMPLE.—The degree of a curve is 4

degrees; its length 520 feet; what is the difference in length

between the inner and outer rails of the curve?

SOLUTION—520 feet = 5.2 stations of 100 feet each. 4 x

5.2 = 20.8. 1 and one-thirty-second = 1.03125 in. 20.8 x 1.03125

= 21.45in. = 1.7875ft.

Rule 2.—Multiply the distance between the center

lines of the rails by the length of the curve in feet and divide

the product by the radius of the track curve.

EXAMPLE.—A 4 degree curve is 520 feet

in length; the distance between the center lines of the rails

is 4 ft. 10½ in.; what is the difference in length between

the inner and outer rails of the curve?

SOLUTION.—The radius of a 4 degree curve is 1432.69 ft.

(See table of Radii and Deflections.)

10½ in. reduced to the decimal of a foot is

.875 4.875 x 520 divided by 1,432.69 = 1.77 ft.

Rule 3.—Multiply the excess for a whole

circumference by the total number of degrees in the curve, and

divide the product by 360. The excess of a whole circumference,

no matter what the degree of curve, is equal to twice the distance

between rail centers multiplied by 3.1416.

EXAMPLE.—A 4 degree curve is 520 feet

in length; the distance from center to center of the rails is

4 ft. 10½ in. ; what is the difference in length between

the inner and outer rails of the curve?

SOLUTION.—The distance between rail centers is 4.875 ft.

4.875 x 2 x 3.1416 = 30.6306 ft. A 4 degree curve for 520 ft.

contains 20.8 degrees. 30.6306 x 20.8 divided by 360 = 1.77 ft.

1088

For light curves laid to exact gauge, the first rule is the

simpler one, but for short curves where the gauge is widened use

either the second or the third method.

These rules should be applied in determining the number of

short rails for curves, when loading material at the supply yard

for forwarding to the track-layers. As previously stated, a safe

rule is one 29½-foot rail per 100 feet for each 6 degrees

of curvature. In laying track with either even or, broken joints,

the required number of short rails must be laid in proper order

if a first-class job is to be expected.

1665. Curving Rails.—When laying track on

curves, in order to have a smooth line, the rails themselves must

conform to the curve of the center line. To accomplish this the

rails must be curved. The curving should be done with a rail bender

(see Fig. 495)

or with a lever, as shown in Fig.

497. The rail bender is preferable.

To guide those in charge of this work, a table of middle and

quarter ordinates for a 30-foot rail for all degrees of curve

should be prepared.

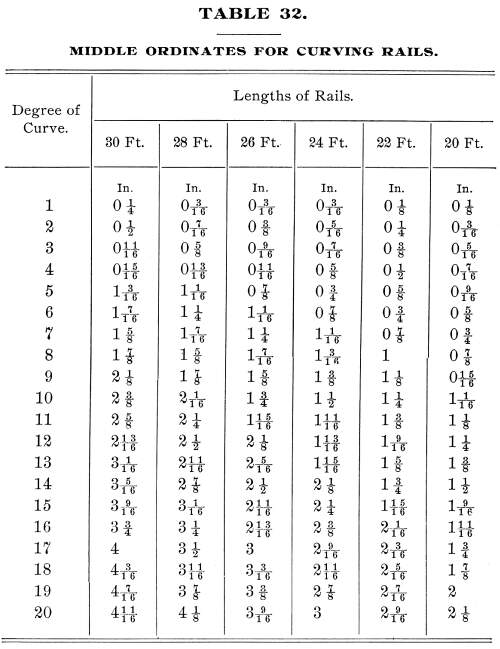

The accompanying table of middle ordinates for curving rails

is calculated by using the formula

m = c (squared) divided by 8 R' (112.)

in which m is the middle ordinate; c, the chord,

assumed to be of the same length as the rail, and R, the

radius of the curve.

EXAMPLE.—What is the middle ordinate

m of a 30-foot rail for an 8 degree curve?

SOLUTION.—The radius of an 8 degree curve is 716.78 ft.

Applying the formula, we have

m = 30 (squared) divided by 8 x 716.78 = 900 divided

by 5,734.24 = 0.157 ft = 1 and seven-eighths ins.

The results obtained from this formula are not theoretically

correct, yet the error is so small that it may be ignored in practical

work. With a table of radii such as is given in the table of Radii

and Chord and Tangent Deflections, a table of ordinates may be

readily calculated by substituting the known values in formula

112.

1089

In curving rails, the ordinate is measured by stretching a

cord from end to end of the rail against the gauge side, as shown

in Fig.517.

Suppose the rail A B is 30 feet in length, and the curve

8 degrees. Then, by the previous problem, the middle ordinate

at a should be 1 and seven-eighths inches. To insure a

uniform curve to the rails, the ordinates at the quarters b

and b' should be tested. In all cases the quarter ordinates

should

1090

be three-quarters of the middle ordinate. In Fig.

517, if the rail has been properly curved, the quarter ordinates

at b and b' will be ¾ x 1 and seven-eighths in. = 1 and

thirteen-thirty-seconds, say 1 and three-eighths in.

With practice, a man having a good eye and good judgment will

soon find his eye measurements closely checking his table measurements.

When a quantity of rails are to be curved for curves of different

degrees, it is a good plan to mark the degree of the curve of

each rail in white paint on the web of the rail on the concave

side. There should be ample force to handle the rails with dispatch,

else much time will be wasted. The use of sledges in curving rails

should under no circumstances be allowed. There is great danger

of fracture, and often a flaw is caused which at the time is not

perceptible, but which may, under the stresses caused by frost

and heavy trains at high speed, result in a broken rail, with

serious consequences.

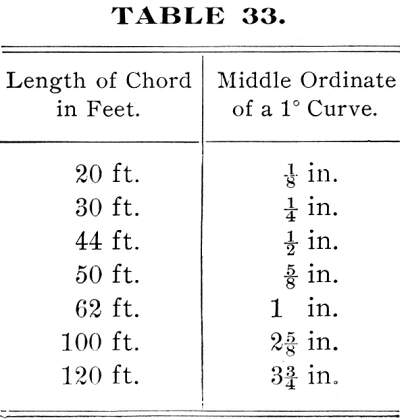

In track work it is often necessary to ascertain the degree

of a curve, though no transit is available for measuring it. The

following table contains the middle ordinates of a one degree

curve for chords of various lengths:

1091

The lengths of the chords are varied so that a longer or shorter

chord may be used, according as the curve is regular or not.

The table is applied as follows: Suppose the middle ordinate

of a 44-foot chord is 3 inches. We find in the table that the

middle ordinate of a 44-foot chord of a one-degree curve is ½

inch. Hence, the degree of the given curve is equal to the quotient

of 3 divided by ½ = 6 degree curve.

Additional examples are given as follows:

1. The middle ordinate of a 100-foot chord is 14¾

inches; what is the degree of the curve?

Ans. 5.6 degrees, nearly.

The degree of the curve is probably 5 degrees 30 minutes.

2. The middle ordinate of a 50-foot chord is 5¼

inches; what is the degree of the curve?

Ans. 8.4 degrees.

The degree of the curve is probably 8 degrees 30 minutes.

3. Calculate by rule 1 the difference in lengths

between the inner and the outer rails of a 7 degree curve 475

feet in length.

Ans. 34.29 in. = 2.857 ft.

4. Solve Example 3 by rule 2.

Ans. 2.827 ft.

1666. Springing Rails into Curve.—Rails should

never be sprung and spiked to a curve; the elastic force of the

steel is constantly acting, and is sure to force the track out

of line. Each passing train, through its centrifugal force, aids

the rails to regain their original form. The result is that in

a short time the curve, especially it a sharp one, wilt show an

angle at each joint. The effect at these angles is to cause a

sudden lurch of the car at each joint, causing not only discomfort

to passengers, but serious and constant wear and strain upon the

rolling stock.

1667. Widening Gauge of Curves.—In passing over

curved track, the car wheels bind hard against the outside rail

at the curve. The reason for this is that the difference between

the gauge of the track and the gauge of the wheels is taken up

by the wheel base, which forms a chord to the curve of the track,

instead of being parallel to the rails, as is the case on a straight

line. To lessen this friction,

1092

the gauge is usually widened on curves to the amount of one-sixteenth

inch per degree, but never to exceed 1 inch on any curve. The

increase in gauge is usually made in quarter-inches, that being

the amount allowed for 4 degrees. The necessity for widening the

gauge on sharp curves is still more apparent when we consider

that provision must be made to accommodate cars of both standard

gauge (4 feet 8½ inches) and for those of 4 feet 9 inches

gauge, common to Southern roads.

When the gauge is not widened, a wide-gauged car is liable

to mount the rail, especially if the flanges of the wheels are

badly worn and sharp. The effect of all curvature is to increase

the train resistance, and on sharp curves, this resistance, due

to friction, becomes so great as to largely reduce the train load.

All train loads are limited by the maximum resistance which they

must overcome. This maximum resistance may be concentrated upon

a single curve, and it is at once apparent that a railroad company

might well incur heavy expense in reducing this curvature, if

by so doing they could add one extra car to each train load. Another

charge against curvature is the loss of time to passenger trains

which can not run over sharp curves, except at reduced speed.

All curves exceeding eight degrees, besides their resistance to

trains, cause a direct loss of time to all fast passenger trains.

1668. Guard Rails on Short Curves.—On straight

track, laid to exact gauge, the guard rail is spaced 1 and seven-eighths

inches from the gauge rail; but when the gauge is widened, as

on sharp curves, the amount of the increase in gauge must be added

to the space between the gauge and the guard rail.

1669. Lining Curves.—A common habit of trackmen

when lining curves is to throw the curve outwards to line. The

effect of this, in time, is to reduce the degree of curvature

at the ends of the curve and sharpen it at the center, besides

crowding the roadway on the outside of the curve.

1093

A safe rule is to always throw the track inwards, i.e.,

towards the center of the curve. It is at once apparent that the

effect of the centrifugal force of the train in passing over a

curve is to throw the track outwards, and in lining curves, the

track should be thrown inwards, if for no other purpose than to

overcome this effect of the trains. The effect of throwing the

track outwards when lining a curve is shown in Fig. 518, in which A B C represents

the true line of the curve and A E C the position of the

tracks due to improper lining.

When track is first laid, there should be a track center stake

driven at every 50 feet and carefully centered with a tack. Before

and after ballasting, the track should be carefully lined to the

center stakes, and if the rails have been properly curved the

track will hold its line, with occasional retouching, for years.

In the case of a badly lined curve, select a piece of track

60 feet in length, which appears to be in good line. There are

few curves, however badly out of line, but will show at least

60 feet of good line. At each end of the 60 feet of good track

set an accurate center stake, and one in the center of the track

midway between them. In Fig.

519, A and B represent the center stakes 60

feet apart, and C the stake midway between them. Stretch

a cord from A to B, and measure the distance from

L, its middle point, to C. The distance C L is

the middle ordinate of a 60-foot chord. Next, mark the middle

point L of the chord, and move the end A of the

chord to C. Measure from B the

1094

distance B M = C L, and carry the measuring cord forwards,

stretching it taut, and in the line C M, as determined

by the offset B M. The forward end D of the cord

will mark the spot for another track center. Then, move ahead

as before, measuring another offset and stretching the cord to

locate another center stake at E, In this way a perfect

curve may be run in without the use of an instrument. It is better

policy to set the track centers in line with the faces of the

stakes for line rather than the tack centers, as the cord is sure

to line properly to the faces of the stakes, but in order to line

their centers they must be practically of the same height, which

is sometimes difficult to obtain, especially if the ballast contains

stone.

Having set all the track centers, select a track gauge which

is square and true, and mark a point midway between the gauge

lines. Then, place the gauge on the track close to the track center,

and direct the men to move the track until the middle point of

the track gauge coincides with the track center. Line up the track

at each track center until the entire curve has been moved to

line; then, repeat the operation, giving the final touches, as

a second lining should be sufficient.

1670. Elevation of Curves.—To counteract the centrifugal

force which is developed when a car passes around a curve, the

outer rail is elevated. The amount of elevation will depend upon

the radius of the curve and the speed at

1095

which trains are to be run. There is, however, a limit in track

elevation, as there is a limit in widening gauge, beyond which

it is not safe to pass.

When we consider that the centrifugal force of a car increases

as the degree of curvature, and as the square of the

speed, we readily see how a slight decrease in speed will

equalize a great increase in curvature.

To illustrate: A car passing around an 8-degree curve will

have double the centrifugal force of a car passing around a 4

degree curve at the same speed. But to neutralize the effect of

sharpening the curve from 4 to 8 degrees, it is not necessary

to halve the speed, but only to reduce it in an inverse proportion

to the square root of the degrees of curvature. Thus, if a speed

of 60 miles per hour is admissible on a 4-degree curve, the speed

on an 8-degree curve is obtained by the proportion 60:

If we again double the degree of the curve to 16 degrees, we

only reduce the admissible speed of equal safety to 30 miles per

hour. Hence, it will be seen that the centrifugal force developed

by an increase in speed is not proportional to the centrifugal

force developed by an increase in curvature. In consequence of

this varying relation between curvature and speed, no fixed rule

can be followed for elevating the outer rail of curves.

It is a safe rule to elevate all curves to suit the highest

speed of trains passing over that part of the track. Ordinarily

freight trains require the same track elevation as passenger trains.

All railroad men know that freight trains repeatedly run at passenger

train speed. The aim of every freight train conductor is to "make

time," and he makes it whenever the grades and train loads

permit.

On rolling grades it is often necessary to run down a grade

at top speed in order to acquire sufficient momentum to carry

the train to the summit of the following grade. Every day fast

running is necessary in order to make up for time lost through

unavoidable delays; hence, if a curved track is elevated to meet

the requirements of passenger trains, freight trains will be equally

well served. All curves, when possible,

1096

should have an elevated approach on the straight main track,

of such length that trains may pass on and off the curve without

any sudden or disagreeable lurch. The length of the approach should

be in proportion to the elevation of the curve and not to its

degree.

A good rule for curve approaches is the following: For each

half-inch or fraction thereof of curve elevation, add 30 feet

or 1 rail length to the approach; that is, if a curve has an elevation

of 2 inches, the approach will have as many rail lengths as ½

is contained in 2, which is 4 times. The approach will, therefore,

have a length of 4 rails of 30 feet each, or 120 feet.

The following formula by Searles, viz.,

c = 1.587 V, (113.)

gives the length of the chord c, whose middle ordinate

is equal to the proper elevation of the outer rail

of the curve for any velocity V in miles per hour.

EXAMPLE.—The curve is 8 degrees, and

the velocity 40 miles pet hour; what is the proper elevation for

the outer rail of the curve?

SOLUTION. -Substituting the given values in formula 113,

c = 1.587 V,

we have c = 1.587 x 40 = 63.48 feet, the length of the

required chord.

To find the middle ordinate of this chord, we apply formula

112.

We have just found c = 63.48 feet, and R = the

radius of an 8 degree curve = 716.78 feet.

Substituting these values of c and R in the above

formula, we have

m = 63.48 (squared) divided by 8 x 716.78 = 4,029.7

divided by 5,734.2 = .71 ft., nearly = 8½ in.

This result is too great. The best authorities on this subject

place the maximum elevation at one-seventh the gauge, or about

8 inches for standard gauge of 4 feet 8½ inches. The gauge

on a 10 degree curve elevated for a speed of 40 miles an hour

should be widened to 4 feet 9¼ inches.

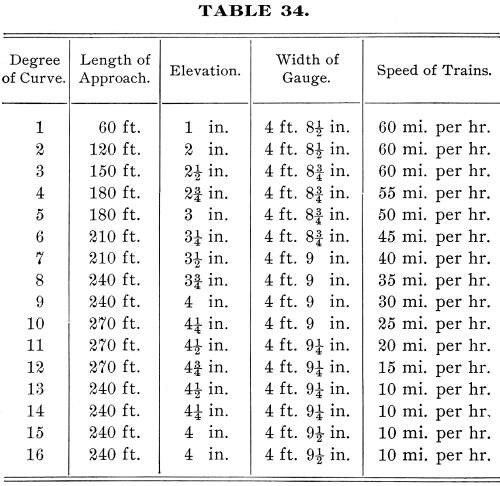

The following table for elevation of curves is a compromise

between the extremes recommended by different engineers. It is

a striking fact that experienced trackmen never elevate track

above 6 inches, and many of them place the limit at 5 inches:

1097

Many persons overrate the objections to sharp curves, especially

where the grades are low. Their great objection is not in their

being an obstacle to high speed, but in their great resistance

to traction. Freight trains, which are usually heavily loaded,

are much more impeded by sharp curves than passenger trains, which

are generally lighter and made up of cars which more readily adjust

themselves to irregularities in line and surface.

No curve exceeding 10 degrees should be placed in the main

line of any railroad. The additional cost of operating and maintaining

a sharper curve would pay for the additional outlay necessary

to bring the degree within the 10-degree standard. Many roads

place the maximum curve at 6 degrees, and though beyond the reach

of many roads, it is a safe standard.

1098

Besides the loss of time necessitated by running slowly on

short curves, there is a much greater loss due to the wear and

tear on rolling stock and upon the rails themselves. The friction

of the wheel flanges against the rails rapidly wears them out,

and the continual lurching and rolling of the cars detract greatly

from the comfort of passengers.

Most of the trunk lines in the United States have been greatly

improved since their first construction, especially in their alinement,

some of them being practically rebuilt. The Pennsylvania R.R.

between Philadelphia and Harrisburg is a striking instance of

the great improvement, both in alinement and grade, of a line

originally cheaply and poorly built. Many of the original curves

have been removed, and all of them lightened. In many places the

original line has been entirely abandoned, and a new and better

one adopted. This road is, however, an exceptional case, as few

lines in the world could afford to make slight changes involving

so great cost.

1671. The Elevation of Turnout Curves.—The speed

of all trains in passing over turnout curves and

crossovers is greatly reduced, so that an elevation of ¼

inch per degree is amply sufficient for all curves under 16 degrees.

On curves exceeding 16 degrees, the elevation may be held at 4

inches until 20 degrees is reached, and on curves exceeding 20

degrees, three-sixteenths of an inch of elevation per degree may

be allowed until the total elevation amounts to 5 inches, which

is sufficient for the shortest curves.

1672. Curve Approaches Between Reverse Curves.—If

possible, there should be a level piece of track, at least 60

feet in length, between reverse curves, besides the elevated approaches

to the curves. When the whole of the intermediate tangent is required

in making the elevated approaches to the curves, commence at the

middle of the intermediate tangent, if both curves are of the

same degree. If, however, they are of different degrees, make

the approach to each curve in proportion to its degree. In elevating

the approaches to the curves, give to the first rail

1099

length an elevation of inch, after which give ½ inch

additional elevation per rail length, or, if necessary, 1 inch

additional elevation, so as to make the total elevation of the

approach equal to the elevation of the outer rail of the curve.

When a curve is compounded, commence to increase or decrease

the elevation far enough back from the point of compound curvature

to give to the second branch of the compound curve the elevation

which it requires. This increase or decrease in elevation is made

at the rate of ½-inch per rail length, precisely as in

elevating the approach to a regular curve. When the changes in

a compound curve are frequent and abrupt, it is best to elevate

the outer rail for the highest degree of the curve and carry this

elevation uniformly throughout the curve.

1673. Putting the Elevation in Curves.—If the track

is in good surface, first catch up all the low joints on the inner

rail of the curve. The elevation of the outer rail is determined

by means of the track level shown in Fig. 520. For leveling track, the edge

a b of the track level is placed upon the rails, and when

perfectly level the bubble c of the spirit level will rest

in the middle of the tube. The steps d, e, etc., of the

track level are made 1 inch in height, so that when the step d

is placed on the outer rail of a curve and the rail raised until

the bubble of the spirit level rests in the middle of the tube,

the outer rail has an elevation of 1 inch. Similarly, the step

e, when brought to a level, would indicate a track elevation

of 2 inches, etc.

Having determined the amount of elevation required for the

curve, the outer rail is raised with the track jack and the ballast

thoroughly tamped under the ties. The elevation

1100

should be about ½ inch in excess of that required, in

order that provision may be made for settlement.

In dressing the track after the elevation has been made, make

the crown of the ballast at not more than one-third of the width

of the gauge from the outer rail, in order to secure drainage.

The raising of the outer rail reduces the outer slope and increases

the inner slope of the ballast. If the curve is sharp, the ballast

on the outer half of the track is practically level and holds

water, instead of shedding it. By crowning the ballast as directed,

thorough drainage is insured.

1674. The Effects of Curved Track upon Locomotive and Car

Wheels.—The effect of all curved track, however easy

the curve, is to wear the flanges and treads of car wheels. This

effect is due to the centrifugal force which forces the flanges

of the wheels against the head of the outside rail of the curve.

The elevation of the outer rail, the widening of the gauge,

and the coning of the car wheels, all combine to reduce this friction

and consequent wear.

Where the elevation is insufficient, the friction increases,

and if the gauge is the same as on straight track, there is great

danger of the wheels mounting the rails, especially if the flanges

are badly worn. The conclusion from many years of experiment and

close observation is that the wear of rails on curved track is

largely due to the driving wheels of the engine. When the tires

become worn, the wear of the rails rapidly increases, and hence

the importance of careful and repeated inspection of the driving

wheels. As soon as they show considerable wear, the tires should

be turned off to true lines. Besides preventing unnecessary wear

of rails, this greatly increases the tractive power of the engine.

When the treads of car wheels become badly worn, especially at

the flanges, there is bound to be more or less slipping of the

wheels. For the outer rail, being the circumference of a greater

circle, should require a wheel of greater diameter than the inner

wheel, if both are to make

1101

the same number of revolutions. This increased diameter is given

by the coning of the wheels, shown in Fig. 521, in which the rail a is

on the outside of the curve. An inspection of the figure will

show that the cone-shaped tread of the wheel b gives a

greater diameter to the wheel at c d than at e f.

In passing around the curve, the flange of the wheel b is

forced against the rail a, while the flange of the wheel

h recedes from the rail g. This increases the diameter

of the wheel b, while decreasing that of the wheel h,

and so the excess in length of the outer rail of the curve is

at least partially covered.

Careful experiment proves that under the most favoring conditions

some slipping of the wheels is bound to occur. The friction

between wheels and rails rapidly increases as the rails become

worn, and, as soon as the head of the outer rail of a curve becomes

badly worn, the outer rail should be taken up and placed on the

inside of the curve, and the inner rail put in its place. This

furnishes almost new wearing surfaces to the wheel, and the life

of the rails is greatly prolonged.

1675. Care of Curved Track.—As curved track

offers greater resistance and greater danger to passing trains

than straight track, special effort and pains should be taken

to maintain it in perfect order. All trackmen know that a low

spot on a curve will cause every car in a train to

1102

lurch heavily towards the low side. By careful watching, and

by prompt and thorough repairs, curved track may be kept in perfect

order. It is highly important that the elevation of the outer

rail be kept uniform, and no foreman, however experienced, should

place dependence upon his eye in estimating curve elevation.

Both the civil engineer and the track foreman will do well

to cultivate each other, the engineer imparting theoretical knowledge

in exchange for practical knowledge. The result will certainly

promote mutual respect and enhance the efficiency of both.

Track Page

| Contents Page

|