|

1148

GENERAL INSTRUCTIONS.

1702. Inspecting a Section from a Car or Engine.—Section

foremen should occasionally ride over their section either

on an engine, a caboose, or the rear car of a passenger train,

and note carefully the action of the car while passing over the

track. A defect in line or surface, which would scarcely have

any effect upon a car running 20 miles an hour, would cause one

running at a speed of 45 miles an hour to lurch violently. This

is owing to the fact that a speed of 20 miles an hour will permit

a car to become righted after passing one defect before coming

to a second, while a car running at a speed of 45 miles an hour

may encounter several defects in line or surface in a second of

time.

If a car lurches badly when passing over a straight line, the

track at that spot is either low or badly out of gauge. If, in

passing over a curve, the car swings to the outside of the curve,

there is not sufficient elevation to the outer rail, but if the

car swings towards the inside of the curve, there is too much

elevation in the outer rail at that place.

1149

An observing, alert man will soon become expert in detecting

the different movements of the car as it swings to either side

of the track, and should determine the cause by walking over the

track immediately after riding over it, and remedy the defects

in the track.

1703. Avoid Attaching Hand or Push Cars to Trains.—Foremen

should never attach a hand or push car to a train to avoid

the labor of pumping or pushing the car to its destination. Many

serious accidents have resulted from such action. The sudden slackening

or stopping of a train is likely to throw the hand or push car

under the train in spite of every effort to prevent it, and serious

injury, if not death, is the sure result.

1704. Always Carry a Track Jack.—Foremen should

never be out on their sections without a track jack. Keep it on

the hand car when not in use, so it will always be available.

In no way is time oftener wasted than in attempting to raise a

rail with a makeshift lever when the track jack has been left

behind at the section house. Frequently, the spikes are drawn

from the ties and the track marred both in gauge and surface by

it.

The track jack is one of the best and most economical tools

in use upon a railroad, and every section should possess one and

make the utmost use of it.

1705. The Track Level.—Always carry a track

level when going out on the section to pick up or surface track.

It is useless to attempt to surface track without a spirit level,

though low spots in a track which has once been put in good surface

may be put in proper surface by sighting.

1706. Rails of Different Heights.—Where rails

of different heights meet at a joint, they should be connected

by a step splice, and an iron shim should be placed under

the low rail, to bring the tops of both rails to the same level.

The shim should be slotted at the sides, and spikes driven through

the slots, to hold the shim in place.

1150

1707. Extra Men.—When a section foreman is about

to largely increase his force for temporary work, he should take

time to carefully plan his work and the disposition of his men.

Work well organized is half done.

1708. Getting Acquainted with the Section.—Every

section foreman should, immediately upon taking charge of his

section, thoroughly acquaint himself with everything connected

with it and his work. He should know the length of his section,

the location and degree of each curve, the number and location

of each bridge, trestle, cattle guard, crossing, and culvert,

the weight, brand, and age of all steel and its location, the

number of panels of snow fence, the height of bridges from the

ground, the location of whistling posts, the- numbers of all frogs,

and any information which can assist a foreman in making out correct

and prompt reports to the roadmaster.

1709. Drilling Rails.—When it is necessary to cut

rails in putting in switches, or in repairing track, the rails

should be full drilled and bolted at every joint. A joint but

half bolted is sure to sag in a short space of time.

1710. Lining Disconnected Track.—When lining

disconnected track that has been washed out, always commence at

the connected end, else it' will be practically impossible to

get the track in line.

1711. Cutting Steel.—Section foremen should carefully

instruct their men how to cut rails. The cut of the chisel should

be a continuous line extending entirely around and square across

the rail. Iron rails require deeper cutting than steel rails.

To break off a rail at the cut, lift up the end nearest the cut

and let it fall across a piece of rail laid on a tie. If but a

short piece of the rail is to be broken off, a sharp blow from

a sledge is the surest way to break it. Hard steel, if cut too

deep, is liable to become softened by the battering of the chisel,

and in breaking leave a rough, unshapely end on the rail. A spike

maul should not be used to strike the head of either chisel or

punch, as it is

1151

sure to destroy the face of the maul and split pieces out of

the head of steel tools. A sledge of suitable weight, made for

the purpose of striking hard steel tools, should be used instead.

Cold chisels when first dressed by the blacksmith are

not always well tempered at the point, and in using a newly sharpened

chisel, light and careful blows should be given first. If the

tool is well tempered, the edge will hold, but if poorly tempered,

the edge will chip slightly. The chisel should then be ground

to a true edge, which generally toughens it, and it will cut a

number of rails before it is necessary to send it to the shop

again.

1712. Distance at Which to Place Danger Signals.—Danger

signals should be placed at distances not less than 3,500

feet in each direction from the point where the track is impassable

for trains. The distance can be measured by counting 117 rails

of 30 feet each from the point of danger, or, where the telegraph

poles are 150 feet apart, place the signals 23 poles distant from

the point of danger. If the point of danger is at the foot of

a heavy grade, where it is difficult to stop a train, the distance

of the danger signal should be increased to even double the ordinary

distance, or the telegraph operator at the nearest station informed

of the danger, so that he may notify the train dispatcher, who

will at once warn all trains within danger, and they can be held

until the track is safe for their passage. Where there is a sufficient

force of men to make repairs, the flagman should remain with the

danger signal until the track is repaired or the train stopped.

In foggy or stormy weather, the flagman must always remain

out with the signals until all danger is passed. As soon as

the track is safe for the passage of. trains, flags, torpedoes,

or other signals should be removed at once.

Foremen should always carry flags and torpedoes on their hand

cars, and fully instruct their men in the use of them. They should

be fully posted on the time of all

1152

regular trains, and should be on the watch for signals carried

by regular trains.

1713. Signals.—In setting a signal

requiring a train to run slowly, called a slow flag,

place the flag on the engineer's side of the track, the

right hand side, slightly leaning, so that most of it can be seen,

and just far enough from the rail to clear the engine and cars.

A slow signal is set out one-half mile, about 17 telegraph

poles, distant.

A red flag or light, which is a stop signal, should

be placed in the center of the track. Two torpedoes should be

placed on the same rail, about 60 feet apart, between the stop

signal and the approaching train.

1714. Location of Whistling Posts and Signs.—Station

whistling posts should be placed one-half mile outside the switch,

not the depot, and on the engineer's side (the right side) of

the track to one approaching the station. Station mile boards

should be placed one mile outside the switches. If the

post were placed but one mile from the station, it would, in large

yards, often fall inside the switches. The object of these signs

is to warn trainmen of the near approach of a station in order

that they may have the train under control before reaching the

station.

Whistling posts for highways should be placed one-quarter of

a mile from the crossing, and on the engineer's side of the track.

Whistling posts or other signs should never be placed in a cut

where they will not be readily seen. If on a descending grade,

place the sign outside the cut, increasing the distance; if on

an ascending grade, decrease the distance. This rule also applies

to sharp curves. All signs carrying a cross-board should have

the board placed at right angles to the track. Highway crossing

signs should be placed parallel to the rails, so that they may

be distinctly read by persons approaching the track. All posts

carrying signs should be vertical, and securely set in the ground,

and so placed as not to come in contact with either trains or

vehicles.

1153

1715. Obstructing the Track.—The track should

never be so used as to obstruct a regular train, nor should any

work be undertaken which can not be finished, and the track made

safe, fully 15 minutes before the train is due. In case of a delayed

passenger train, the track must be kept constantly safe and clear,

and if repairs must be made, a responsible man, preferably the.

foreman himself, should remain out with signals until the track

is safe and clear.

Some foremen have a habit of leaving the hand or push car on

the track while repairs are being made. This is a dangerous practice,

and contrary to the rules of any well-managed railroad. The hand

car should not only be kept clear of the track when not in use,

but should not be left in the way of road or farm crossings.

1716. Hand-Car and Tool Houses.—Hand car and tool

houses should be placed outside the switches at yards and stations,

so that trains standing on the side track will not deter section

men with their band car from going to work. Tool houses must be

far enough from the track to prevent obstructing the view of passing

trains.

1717. Throwing Switches.—Foremen should

not throw switches for trivial reasons. An empty hand car or push

car should always be carried from one track to another, and, if

carrying a light load, it can be handled without throwing a switch.

Most foremen carry a switch key, but it should be used with proper

discretion and never in the absence of the foreman. The

person tending to the switch should always remain by it until

it is set for the main track and locked. Any foreman who makes

a practice of throwing switches where it is unnecessary' should

be discharged at once.

1718. Care of Tools.—The section foreman is responsible

to the railway company for all tools and other supplies issued

to him. The systematic use and care of tools will greatly increase

their efficiency and prolong their

1154

service, and it is evident that the foreman can not better

serve his company than by instructing his men in the proper handling

and care of tools.

Hand cars and push cats should be oiled regularly, the axle

and other boxes kept tight, and the cars kept always ready for

service. Hand cars should not be used to carry steel except in

emergencies, and then only a light load should be taken, the rails

being placed on both sides of the car so as to balance. Both rails

and ties should be transported on the push car.

Shovels figure largely in the tool account chargeable to track

repairs. On most sections this account is unnecessarily large,

owing to the many improper uses to which the shovel is put. A

shovel should never be used to hold up the end of a tie for spiking,

nor driven into a tie in place of a pick to pull the tie into

its trench in the track. As soon as the edge begins to turn, it

should be straightened, and, if necessary, trimmed with a cold

chisel. Proper care will often double the life of a shovel.

Claw bars should never be used to pry up the track, and, above

all, in frosty weather, as the claws are then easily broken, and

are always difficult to repair.

1719. Care of Material.—A sure test

of a good foreman is his care for all material placed in his charge.

Whenever track repairs of any kind are made, all loose material

of every kind should be collected, and, with the exception of

rails, should be carried to the section house, where it may be

sorted. Much old material, such as splice bolts and spikes, may,

with a little straightening, be made to serve a second time and

be as serviceable as new material. All old iron should be piled

in places convenient to the track, whence it may be shipped at

the direction of the roadmaster.

1720. Care of Station Grounds.—It is particularly

to the section foreman's interest to keep the station grounds

in perfect order. By a little thought and planning, he can find

time to grade the approaches to the station, plant a few

1155

shade trees, and do some sodding where it will tell. This work

must not be done at the expense of regular track work, but a spare

hour is often available, and the results, if the time has been

wisely expended, amply pay for the outlay. Neat station grounds

'encourage travel, and are sure to win the approbation of superior

officers.

1721. Work-Train Service.—The foreman in charge

of a work train should make it his business to keep his men at

work whenever the train is delayed. There is always plenty of

work to do along the track at any point, and by proper forethought

and planning, these unavoidable delays may be turned to full account.

Every work train should be in charge of a thorough trackman,

who should, in addition, be thoroughly competent to run a train.

Work-train conductors and foremen in charge of gravel pits

or of steam-shovel outfits should receive their orders from and

be responsible to the roadmaster of the division upon which they

are working. They should send in a daily report to the roadmaster,

and every evening after quitting send in to the dispatcher a

lay-up report, stating where they will work the following

day. Work trains should always lay up at a telegraph station.

Conductors in charge of work trains should see that all axle

boxes are properly packed and oiled, and any accidents to cars

or any part of the outfit should be promptly reported to the roadmaster.

1722. Track Inspection.—There should be a well-organized

system of track inspection on every railroad. The amount of inspection

should be in proportion to the excellence of the track and the

amount of traffic. Whatever the amount of traffic, the entire

section should be inspected each day. In ordinary weather this

work may be entrusted to a careful section hand, but in stormy

weather the section foreman should give his entire section

a careful inspection. It is best that the track inspection, especially

at the more dangerous points, should be made before the passage

of express

1156

trains. On double-track roads where the traffic is heavy, track

inspection is performed by regular track walkers. They should

always carry a track wrench, to tighten loose bolts, and a flag

and, torpedoes for signals. During the winter months, when the

ground is frozen solid, the frost, which hinders many kinds of

general track work, is constantly heaving the track out of line

and surface, and greatly increasing the danger of accident. A

rule requiring the section foreman to see his entire section daily

should be strictly enforced. During extremely cold weather the

track requires constant watching. During heavy storms, it is a

good plan to go by train against the storm, to the end of the

section, and inspect the track while returning on foot. Two or

three inspections in a day are none too many for severe, stormy

weather.

1723. Methods of Work.—Every foreman should be

on the alert to learn new and approved methods of work. By careful

thought he may devise time and labor-saving methods himself. Work

slowly done is not necessarily well done. In fact, expedition

is an adjunct to excellence, as no man can do work rapidly without

giving it his full attention, and any work, however simple, that

has heart put into it, will show it by superior excellence.

1724. Discipline.—A foreman to succeed must be

superior to his men both in knowledge and in force of will. Abusive

and profane language will soon demoralize men, robbing them of

all respect for their foreman and for themselves. Patience in

teaching men their duties and habitual fair treatment will make

an enviable reputation for any foreman. He will always receive

prompt and efficient service from his men, can always count on

a full gang, and can readily increase his force for an emergency.

Railroad companies always prefer to fill their important offices

with men who have been tried and promoted in their own service.

The young foreman may be sure that competence and faithfulness

will not go unrecognized or unrewarded. He should take advantage

of every opportunity to increase his know

1157

ledge of his craft, and do all in his power to make it rank

as a profession.

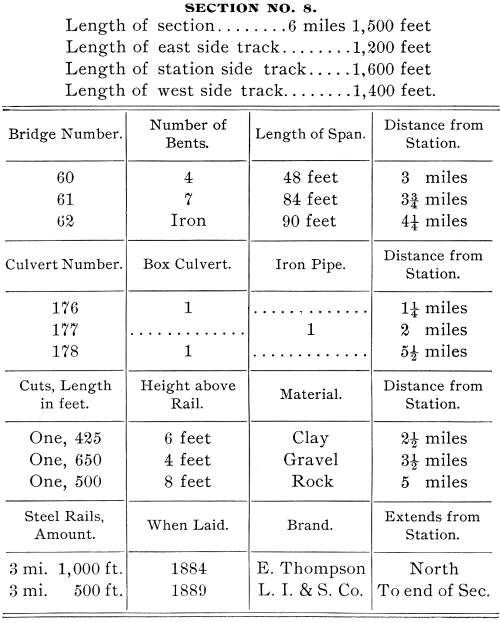

1725. Section Records.—Every section foreman

should keep a record of everything connected with the track under

his charge. This record should be neatly and clearly arranged

and should contain all information which may be used as a basis

for estimates, for the location of structures, or for the distribution

of material.

The following will suggest suitable forms for such a record:

1158

1726. Average Day's Work for One Man.—The following

is a list of the various kind of labor connected with track work,

and gives the amount of each which a good man can perform in one

day. This will serve to show the relation existing between the

labor of one man and a gang of men at any of the different kinds

of work specified:

One man can

Place on a grade one-eighth of a mile of ties.

Spike one-tenth of a mile of track laid on soft ties.

Spike one-fourteenth of a mile of track laid on hard ties.

Splice and bolt one-sixth of a mile of track.

Clean with a shovel one-eighth of a mile of average weeds.

Unload 10 cars of gravel.

Unload 8 cars of dirt.

Load upon cars, 18 to 24 cubic yards of gravel.

Load upon cars, 20 to 25 cubic yards of dirt.

Load coal into buckets for engines, 15 to 20 tons.

Unload coal into sheds, 25 to 30 tons.

Put into dirt ballast track, 20 new ties.

Put into gravel ballast track, 15 new ties.

Put into stone ballast track, 8 to 10 new ties.

Do labor equal to ballasting 60 feet of gravel ballasted track.

Do labor equal to ballasting 35 feet of stone ballasted track.

Chop 2 cords of 4 ft. wood.

Make 15 to 25 hard wood ties.

Make 35 to 40 soft wood ties.

Sixty men can lay one mile of track in a day.

1727. Tables of Material Required for One Mile of Track.

Tons of Rail

Required

Number of

Cross-ties Required

Number of

Rails, Splices and Bolts

Railroad

Spikes

Number of

Track Bolts

Track Page

| Contents Page

|